Feeding mechanism of multi-head ribbon loom

A ribbon loom and multi-head technology, which is applied in the field of ribbon sewing machines, can solve the problems of low processing efficiency, inability to realize several ribbon conveying, folding and feeding, and achieve the effect of automatic feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

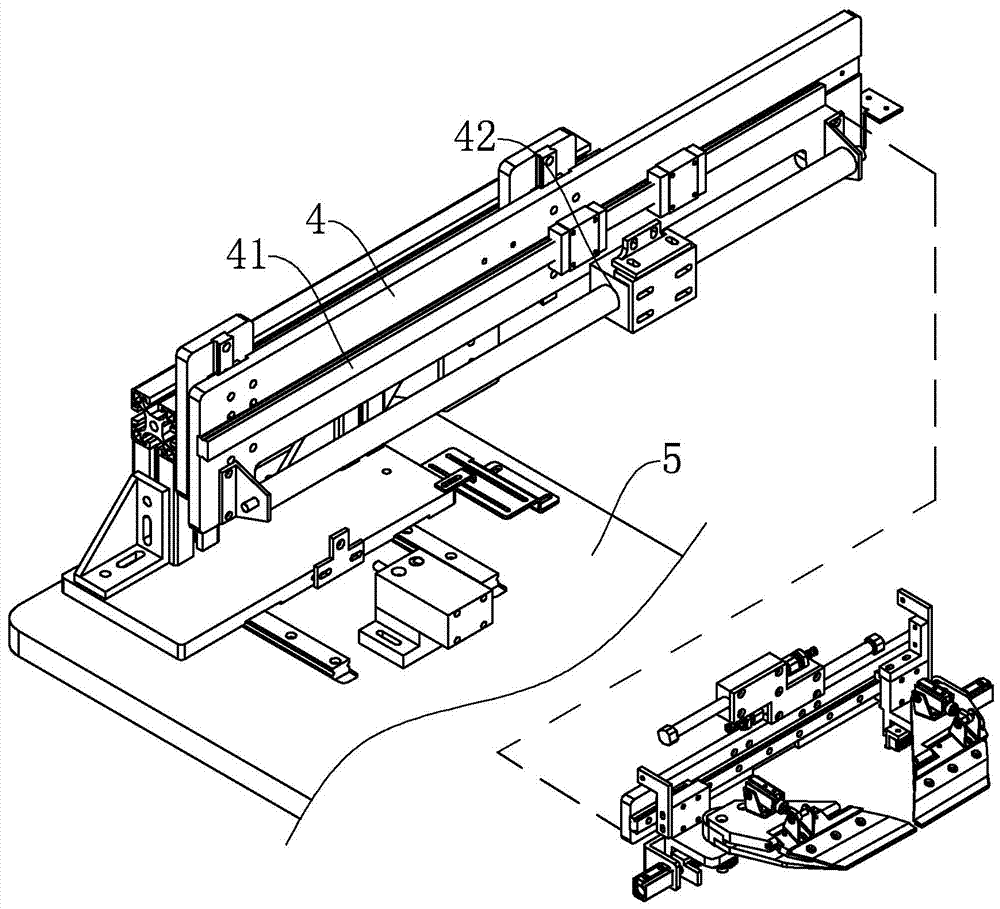

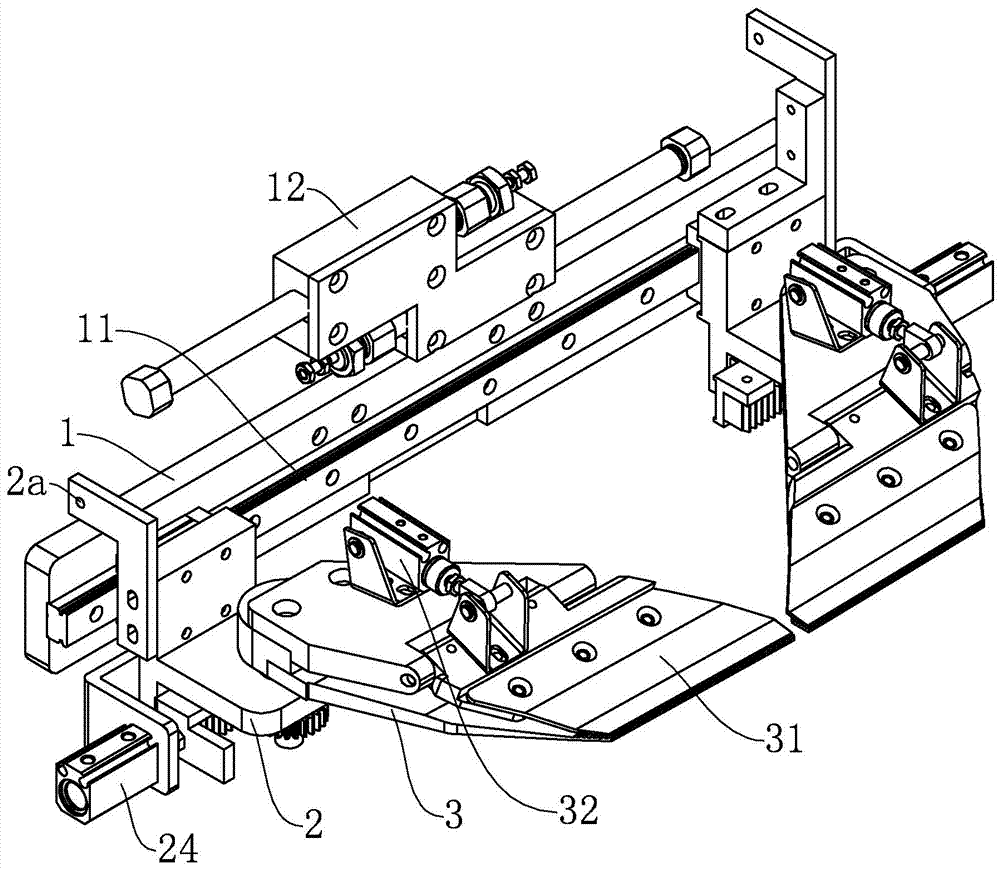

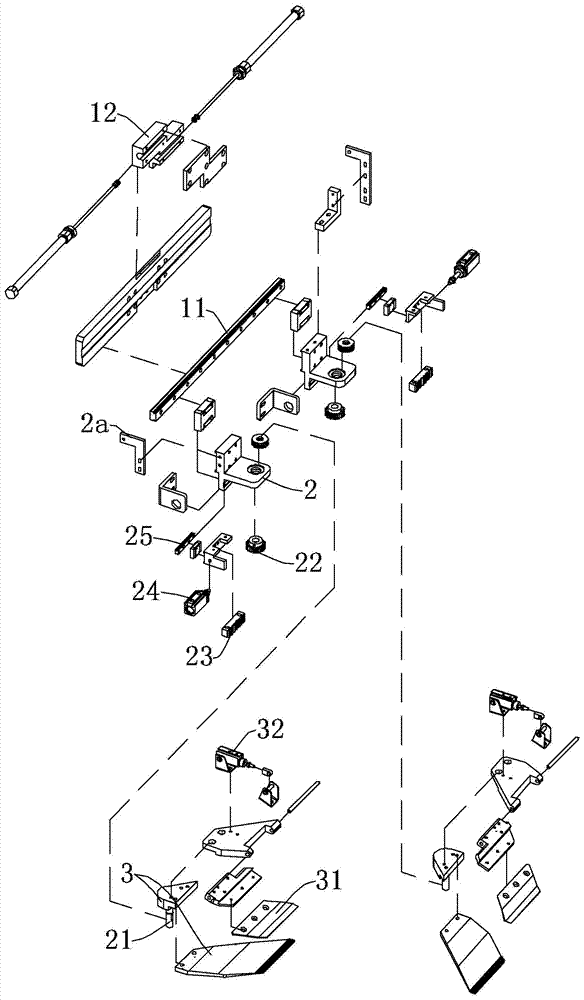

[0022] Figure 1 to Figure 3 Shown is the structural representation of the present invention.

[0023] Wherein the reference numerals are: mounting seat 1, horizontal guide rail 11, cylinder seat 12, clamping seat 2, driving plate 2a, rotating shaft 21, transmission gear 22, transmission rack 23, second driver 24, transmission guide rail 25, the first A splint 3, a second splint 31, a material clamping cylinder 32, a feeding mounting plate 4, a feeding guide rail 41, a rodless cylinder 42, and a worktable 5.

[0024] A feeding mechanism of a multi-head loom according to the present invention includes a mounting base 1, on which are two clamping seats 2 capable of horizontal movement, and a first driver for adjusting the distance between the two clamping seats 2 . Each clamping seat 2 is provided with a rotatable webbing clip and a second dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com