Light wallboard mandrel core pulling device and core pulling method thereof

A core-pulling device and a technology for lightweight wall panels, which are applied to ceramic forming mandrels, ceramic forming cores, etc., can solve the problems of mandrel fixing and cumbersome disassembly, and achieve the effects of simple movements, simple connection methods, and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

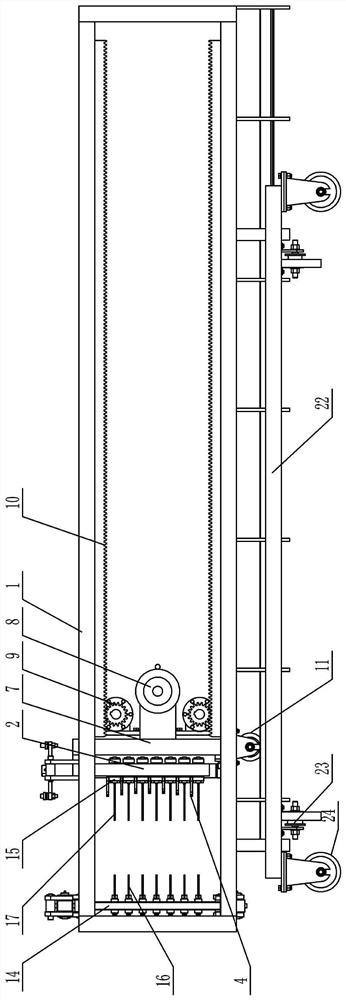

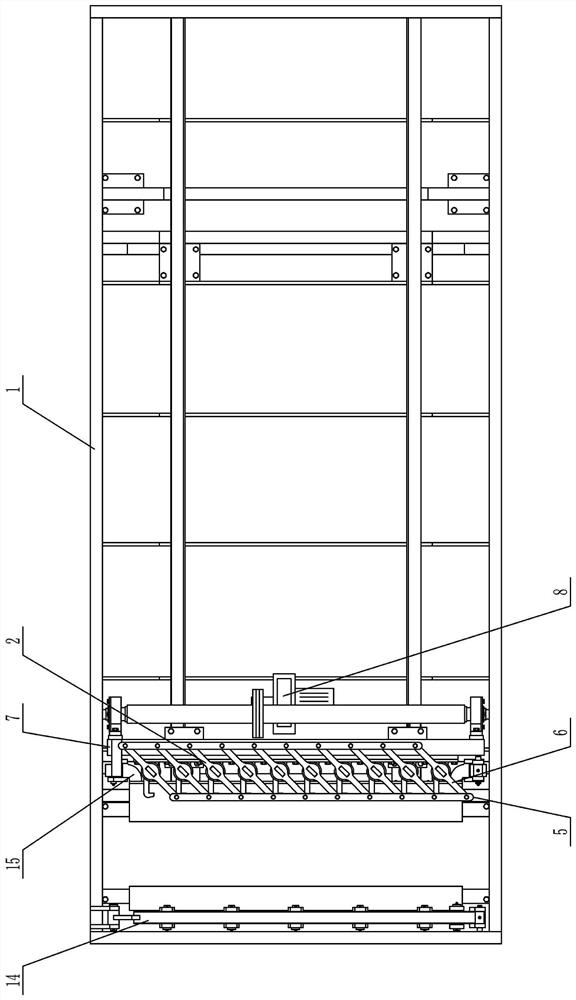

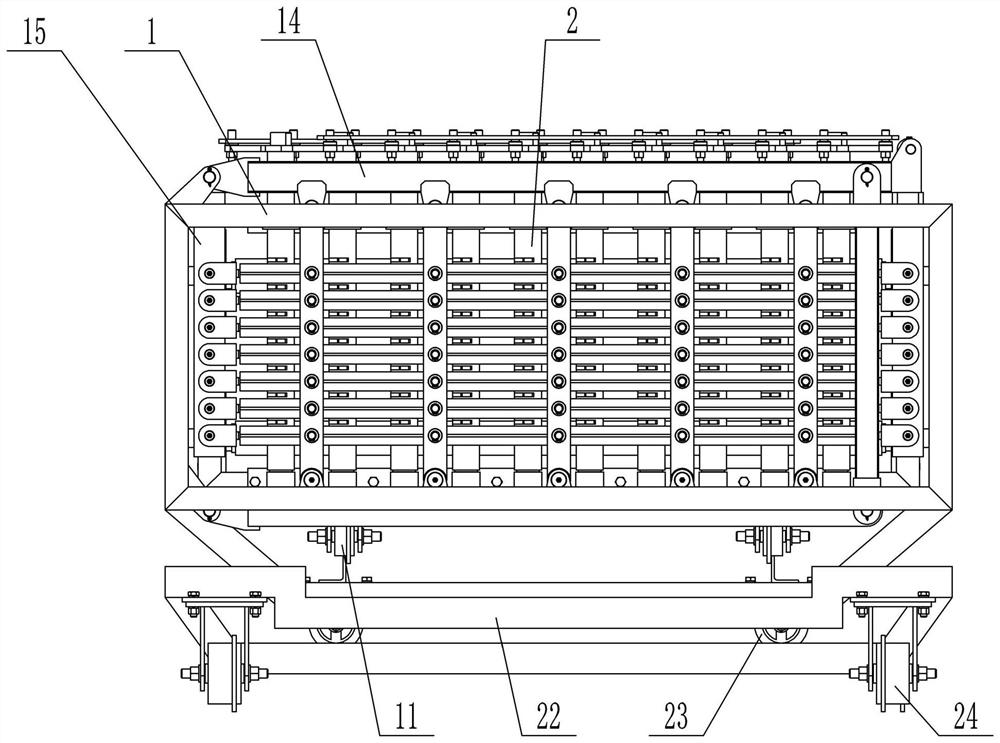

[0038] like Figure 1 to Figure 6 As shown, this embodiment provides a light-weight wallboard mandrel core pulling device, including a core bearing support bracket and a mandrel extraction support 2 arranged on the main frame 1. In the extraction direction of the mandrel, the core bearing support bracket One end is fixed on the main frame 1, and the other end is close to the mandrel extracting bracket 2, and can move synchronously with the mandrel extracting bracket 2 along the extracting direction of the mandrel; the core bearing bracket is used to support the extracting mandrel, and the mandrel extracting bracket 2 Include a connection capable of connecting or disconnecting a mandrel end.

[0039] When in use, use the connecting part on the mandrel extracting bracket 2 to fix and connect the end of the mandrel. After the fixing is completed, the movable end of the mandrel extracting bracket 2 and the core bearing bracket move along the axial direction of the mandrel, and the m...

Embodiment 2

[0050] The present embodiment provides a core-pulling method for a light-weight wallboard mandrel, which includes the following steps:

[0051] 1) Adjust the position of the bracket 22 and the main frame 1 through the first adjustment wheel 23 and the second adjustment wheel 24, so that the mandrel is inserted into the interval between the adjacent front row plates 16;

[0052] 2) Start the motor 8 and rotate the electric gear 9 on the rack 10, thereby driving the rear discharge shaft support 15 and the mandrel extraction support 2 to move toward the end of the mandrel, when the end of the mandrel is on the rear plate 17 Turn off the motor 8, then drive the linkage rod 5 and the linkage arm 6 to swing through the force-applying end, and then drive the hook shaft 3 to rotate, so that the hook 4 enters the interval between the adjacent rear plates 17, and hooks the fixing ring at the end of the mandrel;

[0053] 3) Start the motor 8 again, drive the rear discharge shaft support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com