Stirring device capable of performing automatic discharging

A stirring device and automatic discharge technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of uneven pressure of stirring paddles, poor homogenization effect, and impossibility of realization, so as to achieve mixing The effect of fast material speed and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in combination with specific embodiments.

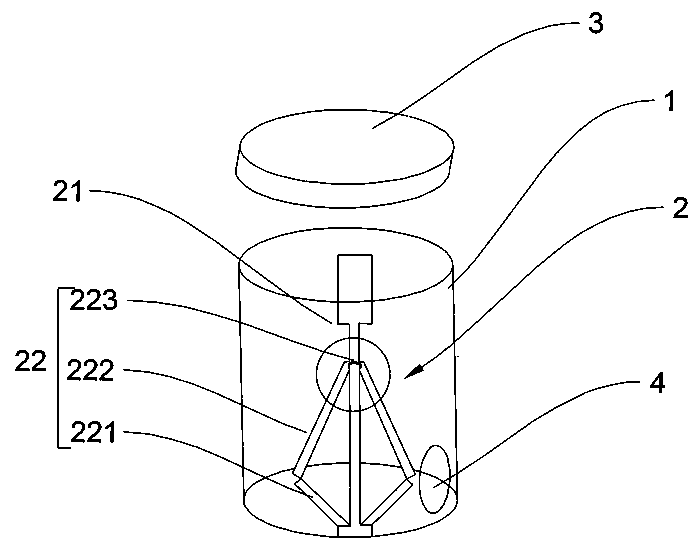

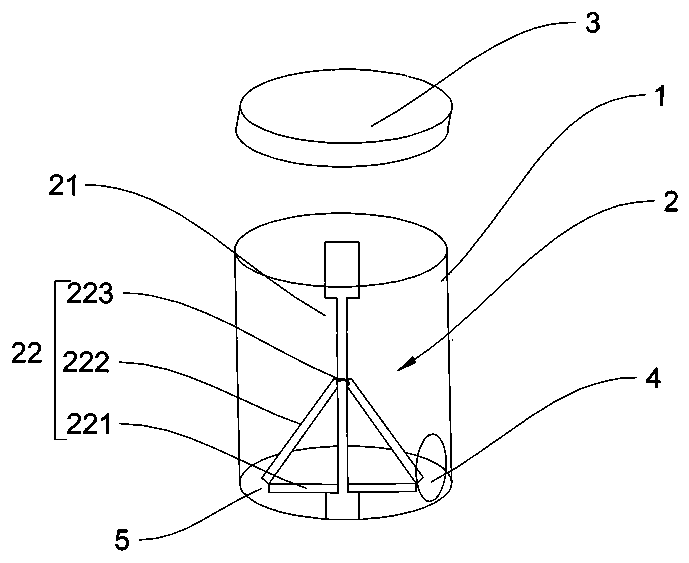

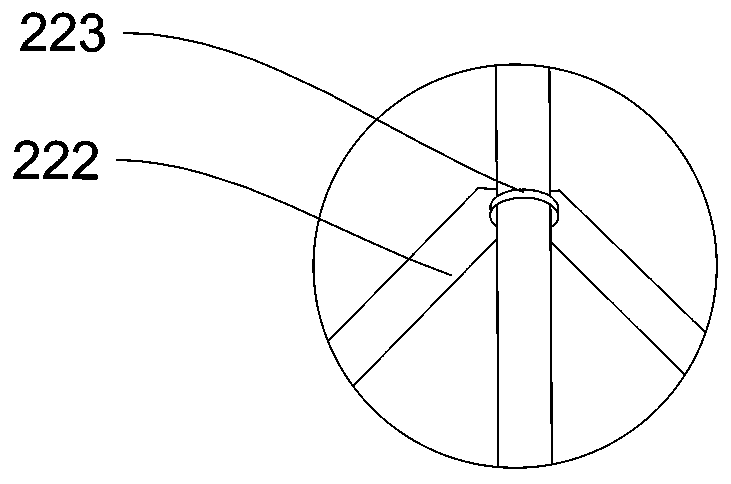

[0020] see figure 1 , figure 2 , image 3 , is a stirring device for automatic discharge, including a cylinder 1, a stirring mechanism 2 is fixed inside the cylinder 1, and the stirring mechanism 2 includes a rotating main shaft 21, a stirring member 22 that is movably connected with the rotating main shaft 21 The stirring member 22 includes a first stirring support 221 movably connected to the bottom end of the rotating main shaft 21, a sliding member 223 sleeved on the rotating main shaft 21 and capable of reciprocating up and down along the rotating main shaft 21, and one end connected to the rotating main shaft 21. The sliding member 223 is movably connected to the second stirring support 222 whose other end is movably connected to the non-fixed end of the first stirring support 221 .

[0021] One end of the first stirring support 221 is flexibly connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com