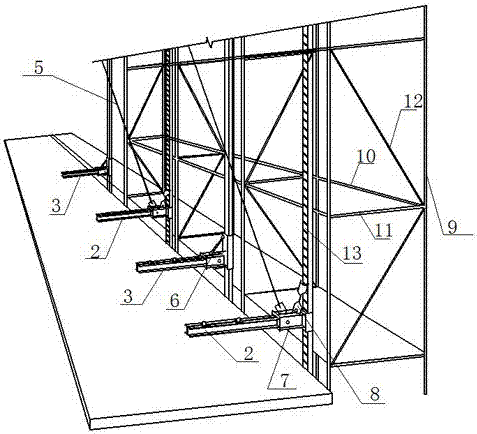

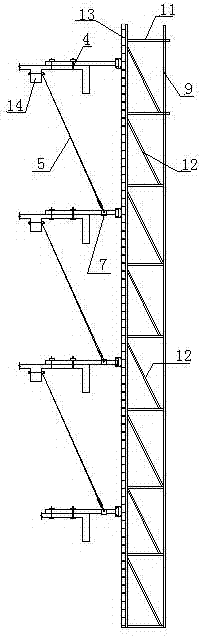

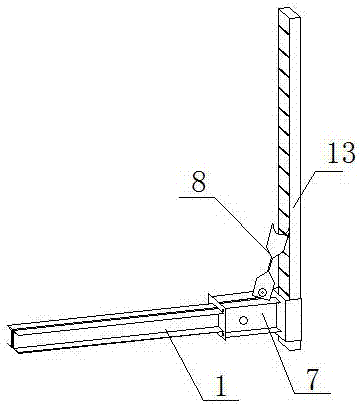

Intelligent attaching lifting scaffold equipment for cambered super high-rise building and construction method

A technology attached to lifting and construction methods, which is applied to the scaffolding supported by the house structure, buildings, building structures, etc., can solve the problems that cannot meet the construction needs of modern super high-rise buildings with various facade changes, and achieve safety and security. Meet the construction needs and ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Project overview: The Science and Technology Research and Development Center Project of China Railway Third Bureau is located in the center of Taiyuan. The project has 38 floors above the ground and 2 floors underground. The surface is variable, and the dimensions of the outer edges of each floor are different. The first floor is an octagon, and the thirty-eighth floor is a quadrangle. The size of the corner gradually decreases, from 13.5m on the first floor to 2.4m, and the size of the front facade gradually increases; the outer edges of each floor are different, and the building area of the 14th floor is the largest (1667m 2 ), the building area of 38 floors is the smallest (1402m 2 ). The climbing angles of the east, south, west and north facades are: (1-4 floors) 96°→90° (13-16 floors)→85° (35-38 floors); the four corner facades The climbing angle is 96° (floor 1-4) → 93° (floor 13-16) → 90° (floor 35-38). The outer dimensions of each layer of the project are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com