Automatic supplementary device for paint immersion

A technology of automatic replenishment and dipping, which is applied to the device and coating of the surface coating liquid, which can solve the problems of easy volatilization, low production efficiency and large fluctuation, and achieve the effect of reducing volatilization and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

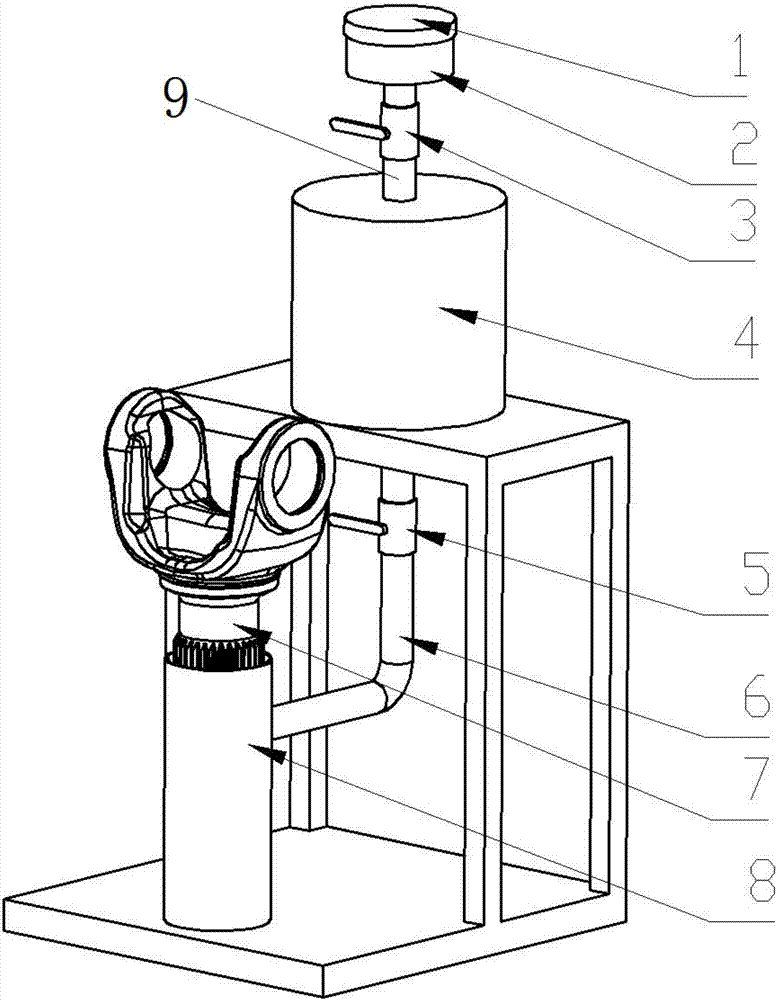

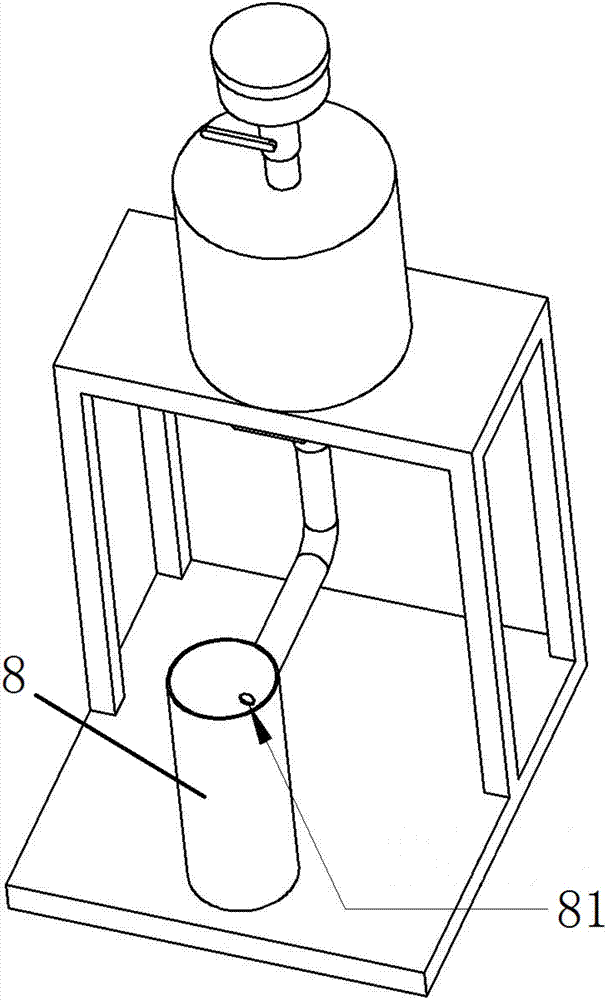

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 Shown, the present invention comprises primer filling tank 2, adds primer tank 4, soaks primer tank 8, and described primer filling tank 2 is connected with adding primer tank 4 by pipeline 9, and in this A primer inlet valve 3 is installed on the pipeline 9, and a primer filling tank cover 1 is covered on the primer filling tank 2; Connected, and a primer valve 5 is installed on the delivery pipe 6 .

[0014] A primer outlet hole 81 is opened on the wall of the dipping primer tank 8 , and the primer outlet hole 81 communicates with the delivery pipe 6 .

[0015] The primer tank 4 is located above the primer tank 8 , and the primer filling tank 2 is directly above the primer tank 4 .

[0016] The working principle of the present invention is: open the primer filling tank lid 1, open the inlet primer valve 3, close the outlet primer valve 5, slowly inject the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com