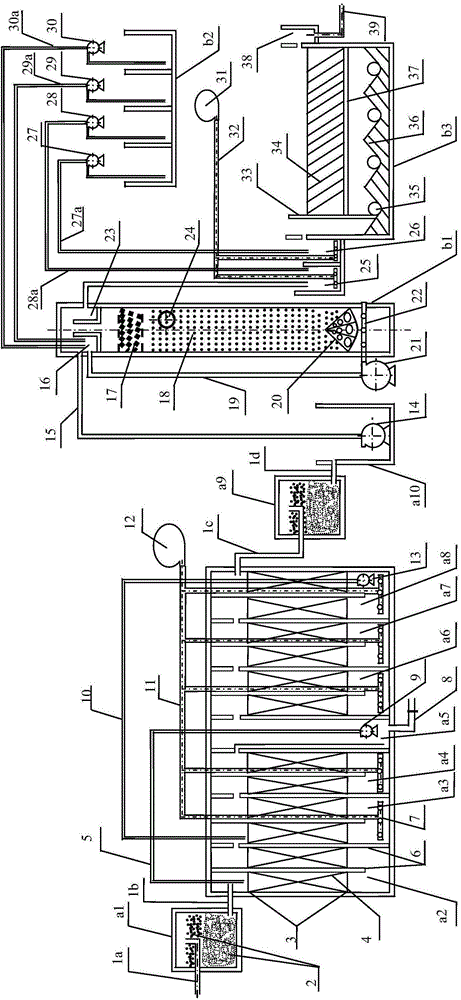

Oil refining sewage integrated combination treatment system and oil refining sewage integrated combination treatment method

A technology for oil refining sewage and treatment system, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Use above-mentioned invention to carry out high-salt refinery sewage treatment experiment, the operation condition of experiment is as follows:

[0041] Biochemical treatment unit: the pH value of refinery sewage is 7.5-9.0, the temperature is 30-42°C, the dissolved oxygen in the anaerobic section of the multi-stage biological treatment system is 0-0.2mg / L, and the dissolved oxygen in the anoxic section is 0-0.5mg / L L. The dissolved oxygen in the aerobic section is 3-4mg / L, the hydraulic retention time is 43.2h, and the reflux ratio is 1. Fenton fluidized bed processing unit: pH value 3.0-4.0, H 2 o 2 The dosage is 1.0g / L, FeSO 4 The dosage is 2.0g / L, and the reaction time is 30min. The influent and effluent COD, ammonia nitrogen concentration and removal rate are shown in Table 1. The COD removal rate is 96.54%, the ammonia nitrogen removal rate is 99.72%, and the effluent meets the A standard of the first-level standard of the "Pollutant Discharge Standards for Ur...

Embodiment 2

[0045] Use above-mentioned invention to carry out mixed type refinery sewage treatment experiment, the operation condition of experiment is as follows:

[0046] Biochemical treatment unit: the pH value of refinery sewage is 7.45-8.43, the temperature is 34-41.2°C, the dissolved oxygen in the anaerobic section of the multi-stage biological treatment system is 0-0.2mg / L, and the dissolved oxygen in the anoxic section is 0-0.5mg / L L. The dissolved oxygen in the aerobic section is 3-4mg / L, the hydraulic retention time is 24h, and the reflux ratio is 1. Fenton fluidized bed processing unit: pH value 3.0-4.0, H 2 o 2 The dosage is 1.5g / L, FeSO 4 The dosage is 3.0g / L, and the reaction time is 45min. The COD, ammonia nitrogen concentration and removal rate of influent and effluent water are shown in Table 2. The COD removal rate is 95.50%, the ammonia nitrogen removal rate is 97.78%, and the effluent meets the A standard of the first-level standard of the "Pollutant Discharge Stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com