An automatic steel bar cutting device

A cutting device and automatic cutting technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of operator safety, low efficiency, easy scalding, etc., to reduce labor intensity, cut fast, The effect of convenient delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

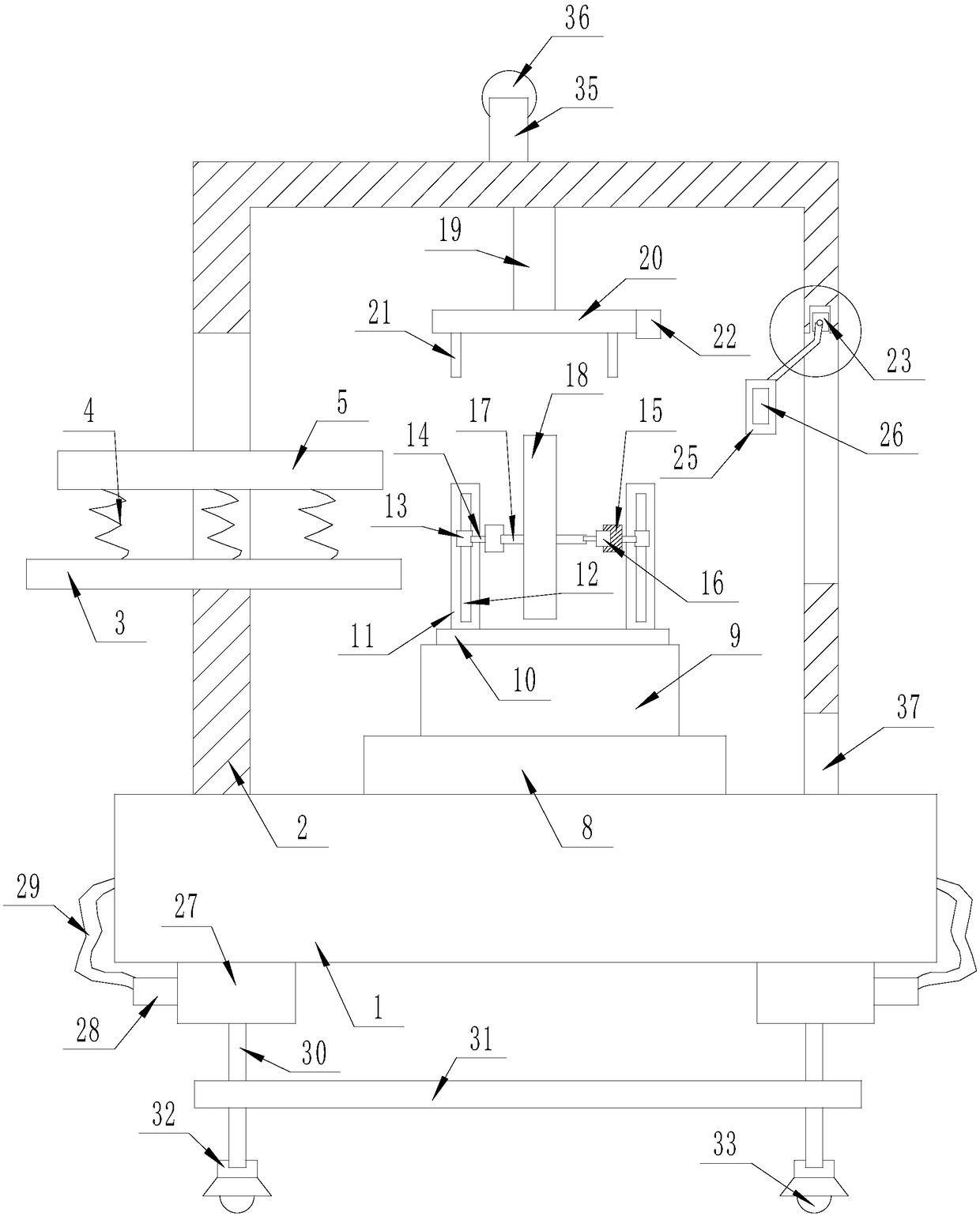

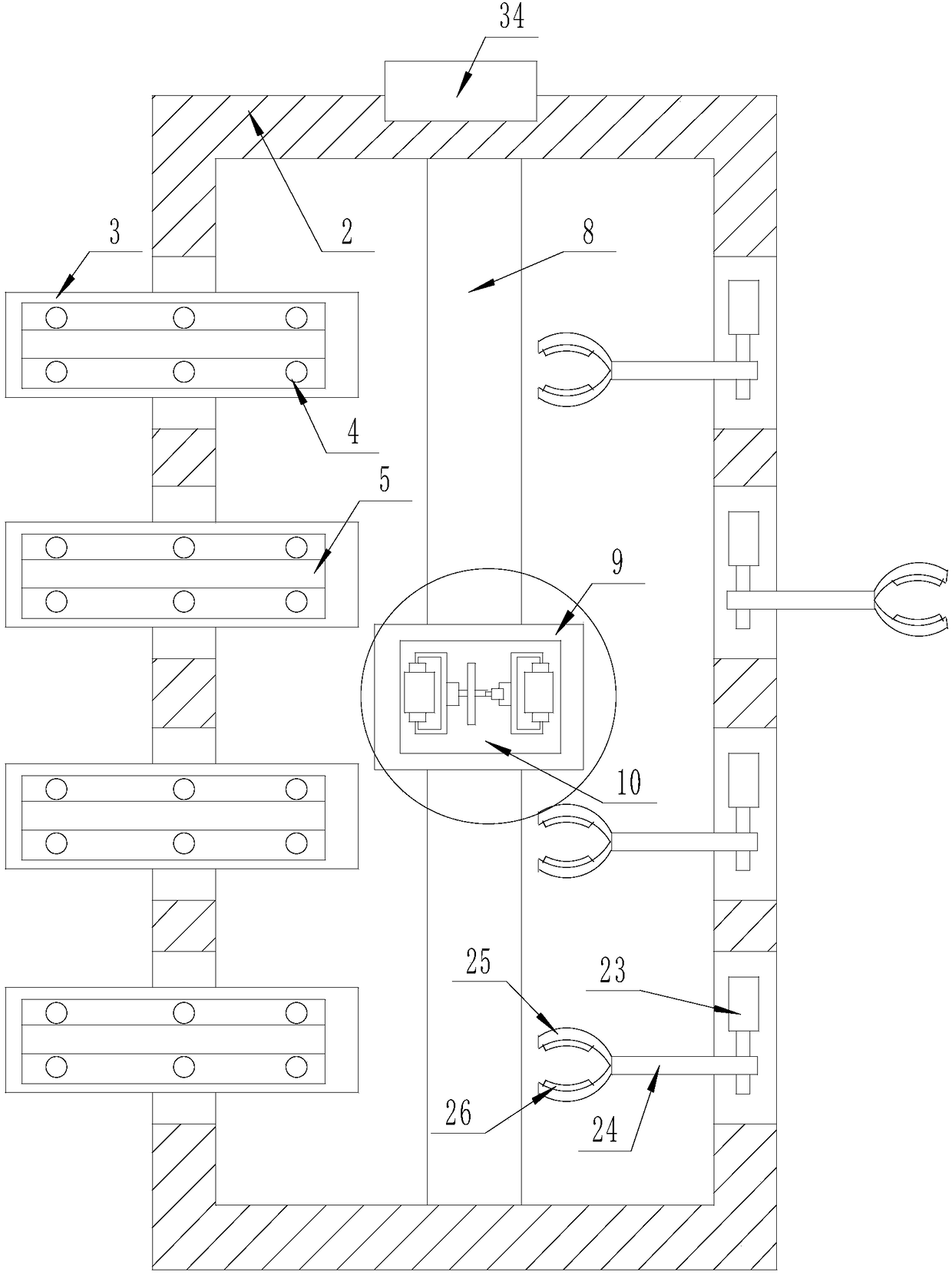

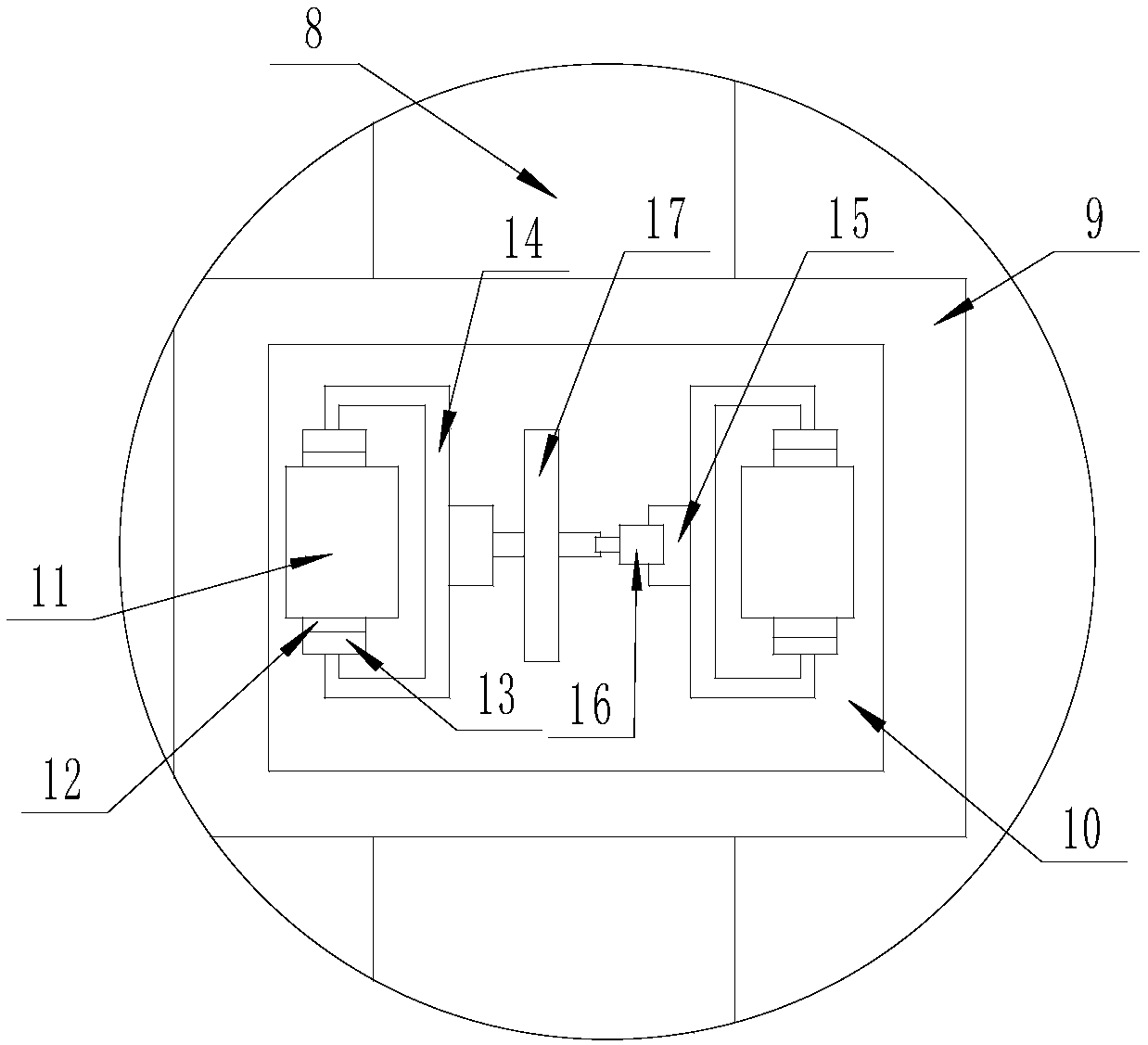

[0026] An automatic steel bar cutting device, comprising a No. 1 bar-shaped base 1, the upper surface of the No. 1 bar-shaped base 1 is fixedly connected with a bar-shaped carrying box 2, and the strip-shaped carrying box 2 is provided with automatic cutting The lower surface of the No. 1 strip base 1 is provided with a moving mechanism, the right side surface of the strip carrying box 2 is provided with a discharging mechanism, and the automatic cutting mechanism is opened on the left side of the strip carrying box 2 A plurality of No. 1 strip-shaped openings on the side surface, a No. 2 strip-shaped support plate 3 embedded in the inner lower surface of each No. 1 strip-shaped opening, a plurality of No. 2 strip-shaped support plates 3 embedded in the upper surface of each The compression spring 4, the arc-shaped carrier 5 fixedly connected to the multiple compression springs 4 on the upper surface of each No. 2 bar-shaped support plate 3, the No. 1 vertical bar-shaped openin...

Embodiment 2

[0029] Embodiment 2: The electronically controlled push rod 19 can be replaced with an electronically controlled lifting support frame, which can also achieve the lifting and lowering effect, and other structures are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com