A Method for Measuring Inertial Parameters of an Infinite Model Powertrain

A powertrain and measurement method technology, applied in the field of inertial parameter measurement, can solve the problems of powertrain measurement inconvenience, etc., and achieve the effect of easy measurement and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0203] A method for measuring inertial parameters of an infinite-model powertrain, the measurement method is based on the MPC700 moment of inertia test bench and its supporting measurement software, the MPC700 moment of inertia test bench includes a base 1 and a measurement table 2, the measurement table 2 located above base 1;

[0204] The top of the base 1 is provided with four moment of inertia support bases 12 and three pressure sensors 11, and the moment of inertia support base 12 can freely twist around the inner rotating shaft 13 of the base 1;

[0205] The top of the base 1 is provided with a measuring platform 2, and the top plane of the measuring platform 2 is provided with a measuring platform reference point A, a measuring platform reference point B and a measuring platform reference point C;

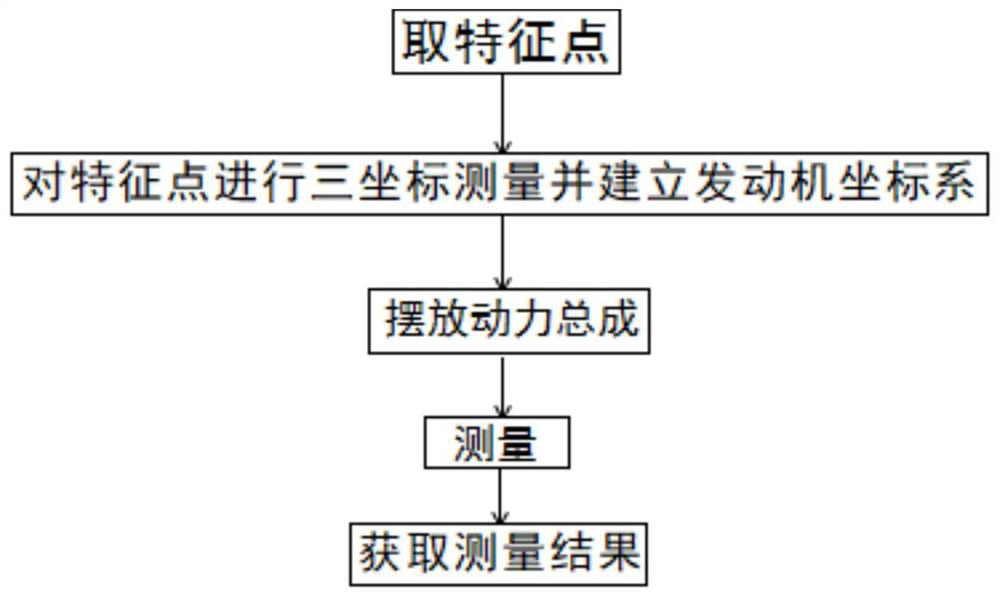

[0206] Step 1. Take feature points:

[0207] Take multiple feature points on the surface of the powertrain, and then enter step 2;

[0208] Step 2: Perform three-coordinat...

Embodiment 2

[0272] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

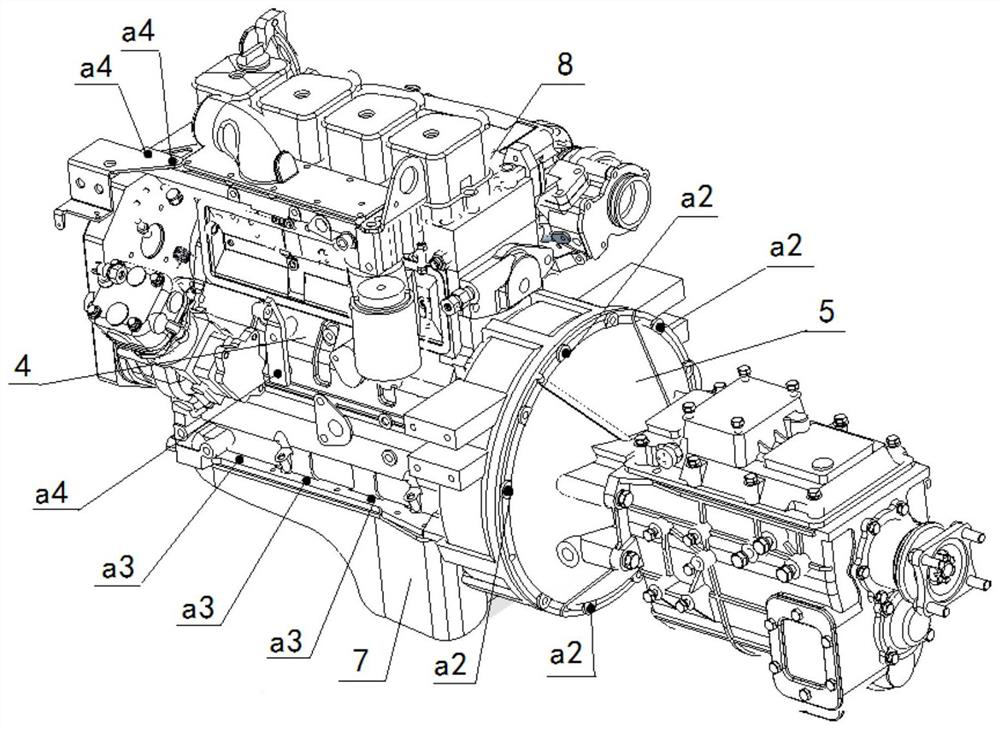

[0273] The rear end face of the cylinder block 4 in the power assembly is connected with the clutch cover 5 through a plurality of connecting bolts, and the feature point a2 of the rear end face is selected at the top of the bolt connecting the end face of the cylinder block 4 and the clutch cover 5;

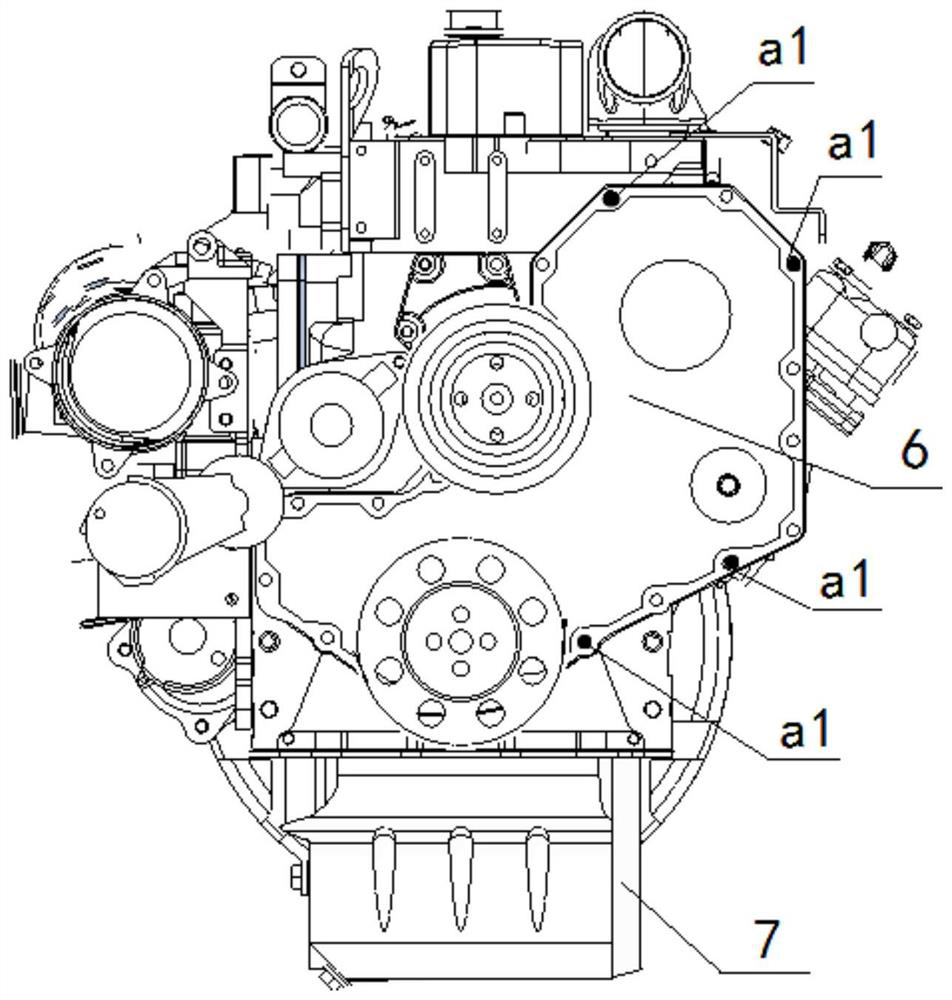

[0274] The front end face of the cylinder block 4 in the powertrain is connected with the front end cover plate 6 of the engine by connecting bolts, and the characteristic point a1 of the front end face is at the top of the bolt connecting the front end face of the cylinder block 4 and the front end cover plate 6 of the engine select.

[0275] The bottom of the cylinder block 4 in the powertrain is connected to the oil pan 7 through connecting bolts, and the upper and lower end surface feature points a3 are selected at the top of the connecting bolts connecting the engine cylinder block 4 and the...

Embodiment 3

[0278] Embodiment 3 is basically the same as Embodiment 2, and its difference is:

[0279] The feature points a3 of the upper and lower end surfaces are selected at the top of the connecting bolts on the cylinder head 8 in the powertrain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com