An optical distance measuring device for a vehicle

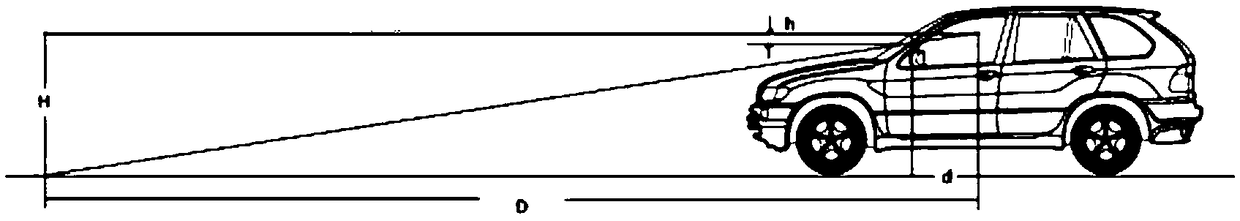

A technology for optical distance measurement and vehicle use, which is applied in the directions of measuring devices, distance measurement, line-of-sight measurement, etc., and can solve problems such as inability to measure distance, inability to determine the position of the horizon line, and inability to determine the observation line of sight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

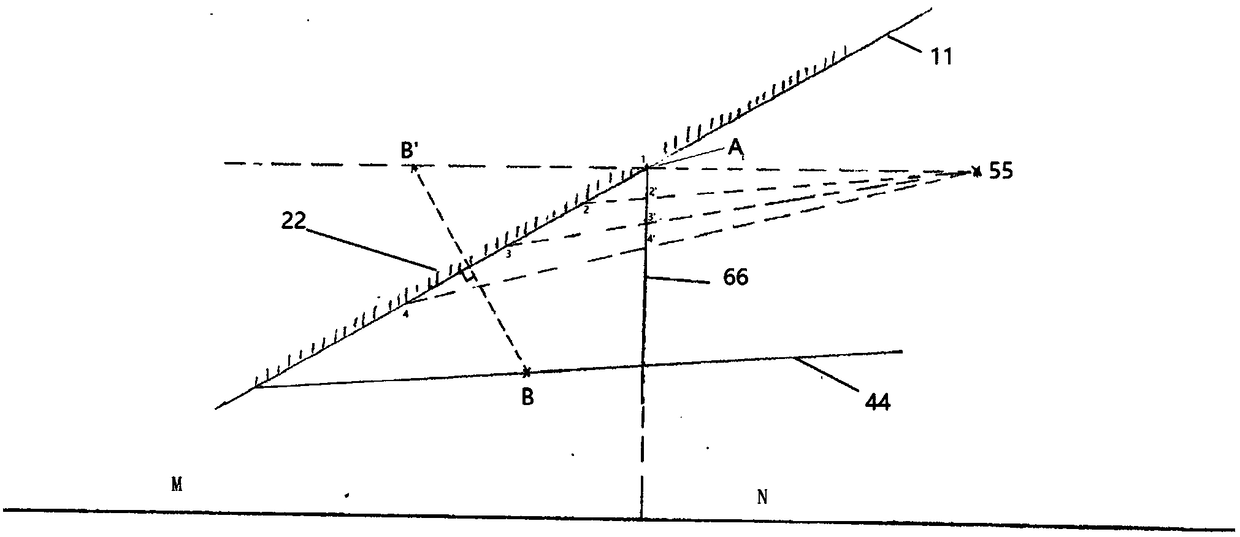

[0044] The overall overview of the technical solution is: windshield scale scale + mirrored eye level reference point, see the schematic diagram figure 2. The eye level reference point B in the figure is a point that is printed or installed at a specific position on the instrument panel using materials that are likely to produce obvious mirror images (high-resolution colors, fluorescent materials, luminous materials or electronic light-emitting devices). The mirror image B' of , and the reference point A of the eye level on the windshield determine the observation eye level. When the two points coincide in the line of sight of the human eye, distance measurement can be performed. Wherein the eye level reference point A is located on the windshield, for example, it can be located directly in front of the driver, and its height is approximately the same as the height of the human eyes 55 . The eye level reference point B can be located on the car dashboard, and the driver can ...

Embodiment 2

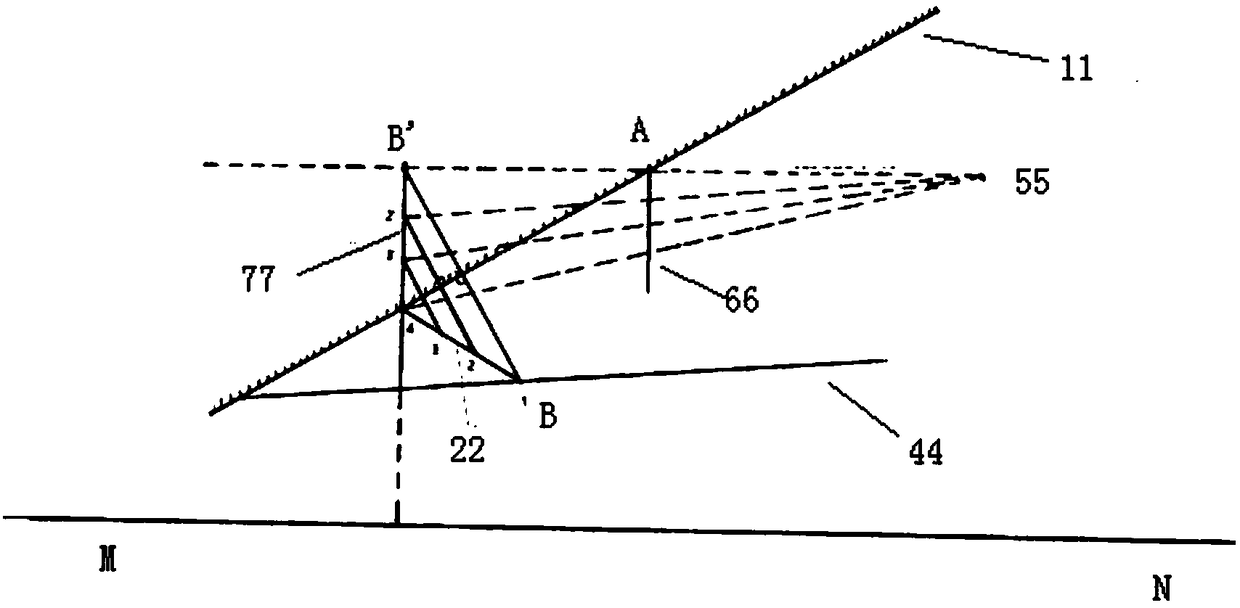

[0046] The overall overview of the technical solution is: mirror scale scale + windshield reference point, see the schematic diagram image 3 . image 3 Among them, the scale scale seen by human eyes is also composed of mirror images. The method is to make a series of scales on dark materials (1, 2, 3, 4...), become the real scale scale, it is placed under the windshield, its first end is used as the eye level reference point B, and its second end extends towards the windshield, which can be connected with the windshield Windshield intersects or does not intersect. This physical scale is imaged in the windshield as a mirrored scale. The eye level reference point A is still pre-made on the windshield. Adjust the position of the physical scale to make it mirror the uppermost scale (1') and point A to form the observation eye level, and then adjust the angle of the physical scale , so that the mirror image of each scale (2', 3', 4'...) and the corresponding scale of the virtua...

Embodiment 3

[0048] The overall overview of the technical solution is: mirror scale scale + eye level reference rod, see the schematic diagram Figure 4 .

[0049] In this scheme, the eye level reference point A located on the windshield in Embodiment 2 is also canceled, so that it is not necessary to make a reference point on the windshield in advance, but use an eye level reference rod 3, two of which The ends are used as the reference point A of the eye level and the reference point B of the eye level. Such as Figure 4 As shown, by pre-calibrating, adjust the placement position and angle of the sight-level reference rod 3, so that the mirror-image points of the sight-level reference point A and the sight-level reference point B at both ends of the baffle glass The reference point A' and the horizon reference point B' are on the observation horizon. Fix the position of the eye level reference rod and it will be used for distance measurement. The scale scale still uses the mirror ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com