Main pump measuring and mounting method of AP1000 nuclear power station

An installation method and technology of nuclear power plants, applied to measuring devices, assembling machines, optical devices, etc., can solve problems such as obstructed line of sight, narrow space, and inability to guarantee measurement accuracy, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

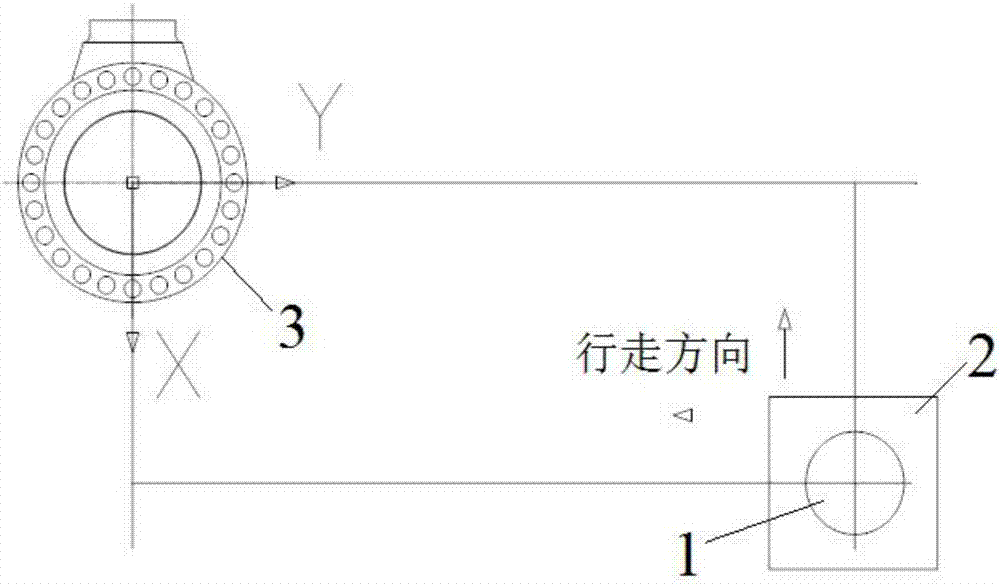

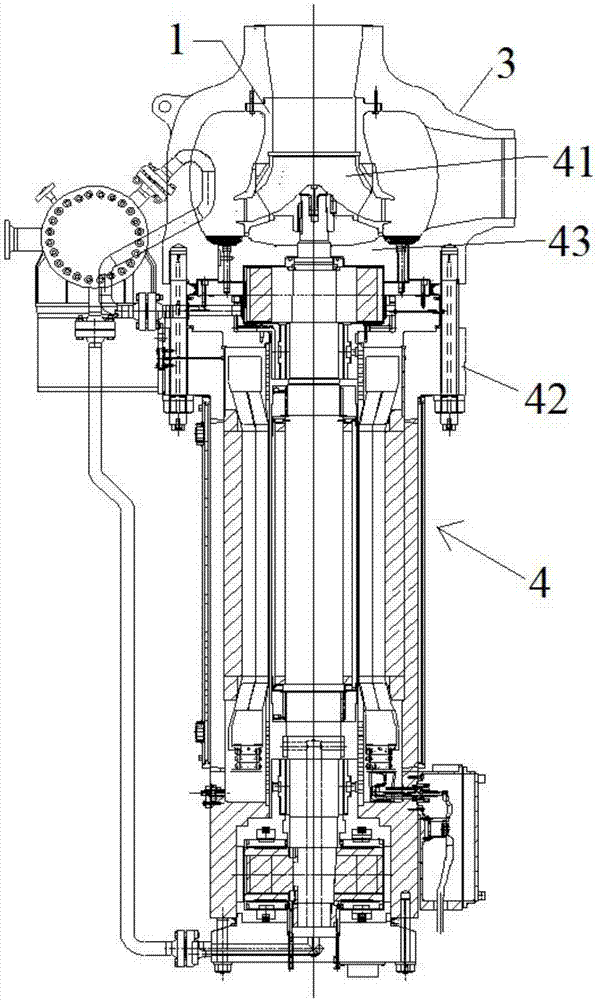

[0026] Below, combine Figure 1-4 , the method for measuring and installing the main pump of the AP1000 nuclear power plant of the present invention will be described in detail. The method comprises the steps of:

[0027] Step S1. Arranging adapter measurement points and adapter modeling measurement points on the suction adapter, establishing a three-dimensional model of the suction adapter according to the measurement results, and analyzing and calculating the shape deviation of the suction adapter according to the three-dimensional model.

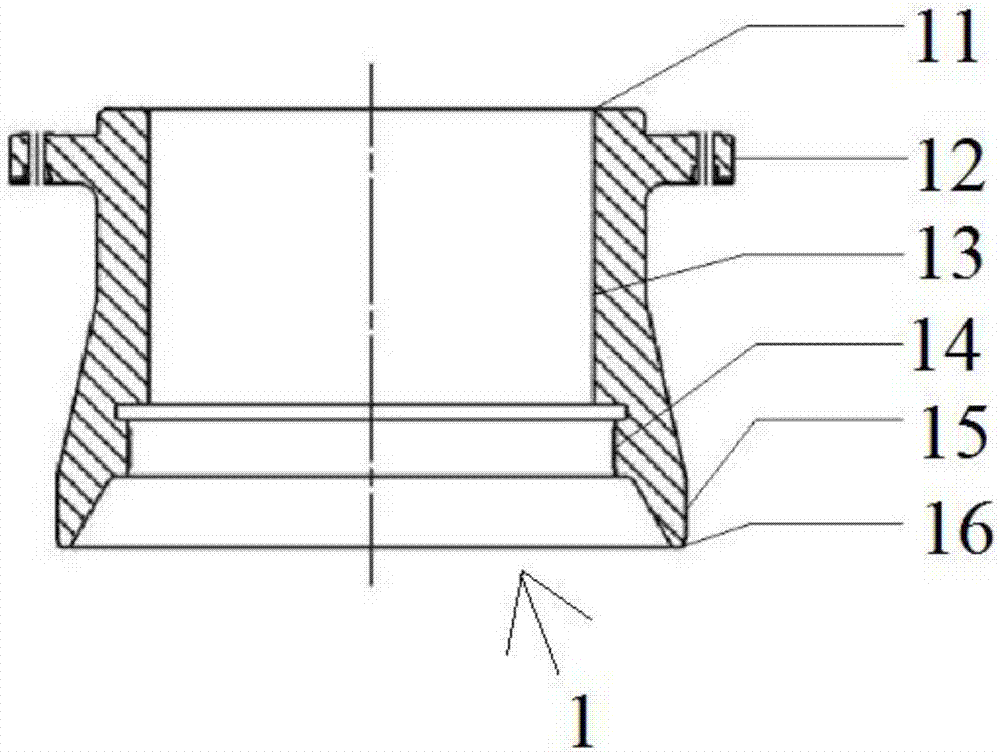

[0028] Such as figure 1As shown, at least 3 adapter measurement points are set on the top flange circumference 11 of the suction adapter 1, and on the upper flange surface cylinder 12, body cylinder 13, impeller-facing cylinder 14, and diffuser-facing cylinder in the suction adapter 1 15 and the bottom outer circle 16 are respectively provided with adapter modeling measurement points which have the same number as the adapter measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com