A pressing device for cardboard collection

A technology of pressing device and cardboard, applied in the directions of transportation and packaging, sending objects, processing of thin materials, etc., can solve problems such as singleness of use, and achieve the effects of preventing slippage, being easy to stack in sequence, and having strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

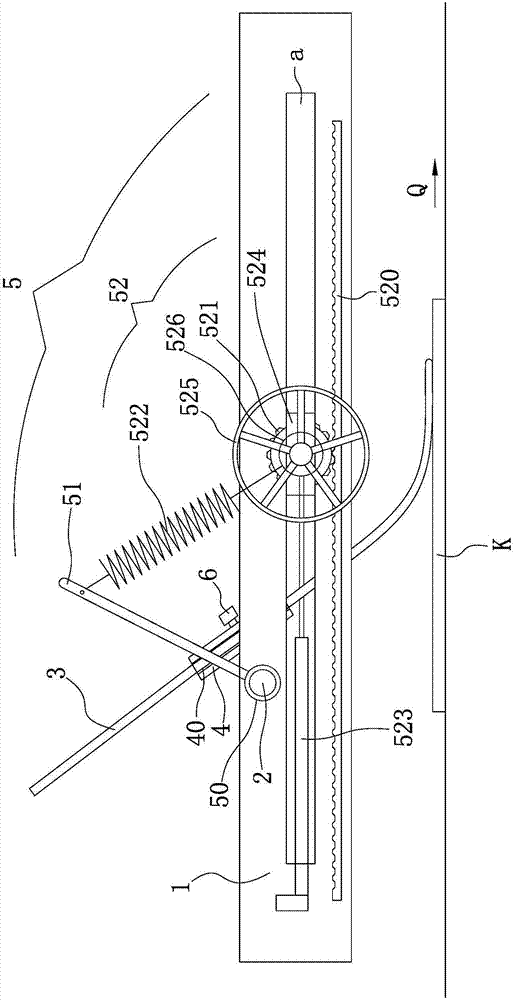

[0022] Such as figure 1 As shown, the pressing device for collecting cardboard provided in this embodiment includes a crossbar 2 that is erected on the receiving frame 1 at both ends and extends horizontally along the direction Q perpendicular to the conveying direction of the cardboard, along the length of the crossbar 2 A plurality of pressing strips 3 distributed in the direction can be pressed on the cardboard K, and the two ends of the cross bar 2 are respectively rotatably arranged on the receiving frame 1, and the pressing device also includes a The sliding sleeve 4 corresponding to the tightening strip 3 and the driving mechanism 5 used to drive the crossbar 2 to rotate around its own axis, wherein the extending direction of the sliding sleeve 4 intersects with the cardboard conveying direction Q, and the pressing strip 3 is arranged from top to bottom The sliding adjustment is set in the sliding sleeve 4, and the lower end of the pressing strip 3 faces the end of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap