Lubricating oil composition with stable friction performance

A lubricating oil composition and friction performance technology, applied in the field of lubricating oil, can solve the problems of affecting the automatic shifting performance of vehicles, the friction performance cannot be guaranteed, and the friction coefficient changes greatly, so as to achieve high adaptability to working temperature and high viscosity index , Improve the effect of anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

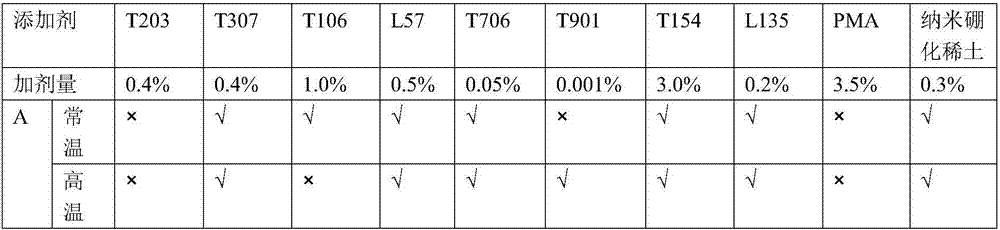

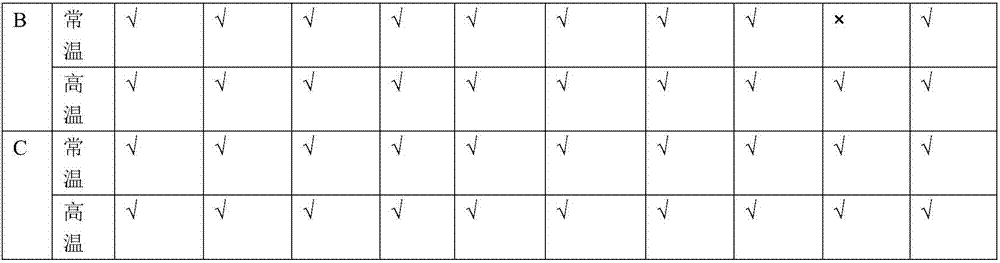

Method used

Image

Examples

Embodiment 1

[0030] A lubricating oil composition with stable friction performance, made of the following raw materials in parts by mass:

[0031] 90.5 parts of mixed base oil

[0032] Polymethacrylate PMA 3 parts

[0033] Zinc dialkyl dithiophosphate T203 0.1 parts

[0034] Phosphorothioate T307 0.3 parts

[0035] Nano boride rare earth 0.1 part

[0036] 6 parts of other functional additives

[0037] In Example 1, the amount of polymethacrylate added is the largest, which has the best viscosity-temperature performance, can well adapt to changes in ambient temperature, has more extreme pressure additives, and has slightly better extrusion performance.

Embodiment 2

[0039] A lubricating oil composition with stable friction performance, made of the following raw materials in parts by mass:

[0040] 87 parts of mixed base oil

[0041] Polymethacrylate PMA 3.5 parts

[0042] Zinc dialkyl dithiophosphate T203 0.4 parts

[0043] Phosphorothioate T307 0.1 parts

[0044] Nano boride rare earth 0.1 part

[0045] 6 parts of other functional additives

[0046]Compared with Example 1, Example 2 increases but the amount of polymethacrylate increases, the overall viscosity increases, the viscosity index increases, the amount of anti-wear additive T203 increases, and the anti-wear property is better.

Embodiment 3

[0048] A lubricating oil composition with stable friction performance, made of the following raw materials in parts by mass:

[0049] Mixed base oil 96.4 parts

[0050] Polymethacrylate PMA 2.5 parts

[0051] Zinc dialkyl dithiophosphate T203 0.2 parts

[0052] Phosphorothioate T307 0.2 parts

[0053] Nano boride rare earth 0.3 parts

[0054] 4 parts of other functional additives

[0055] This embodiment increases the proportion of mixed base oil, reduces the polymethacrylate, and the viscosity of the oil product decreases, but increases the amount of nano-rare earth functional additives, which can ensure lubrication and reduce friction at low viscosity, and P, S content is low.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap