A high-definition scratch-resistant and waterproof optical glass film and its preparation method

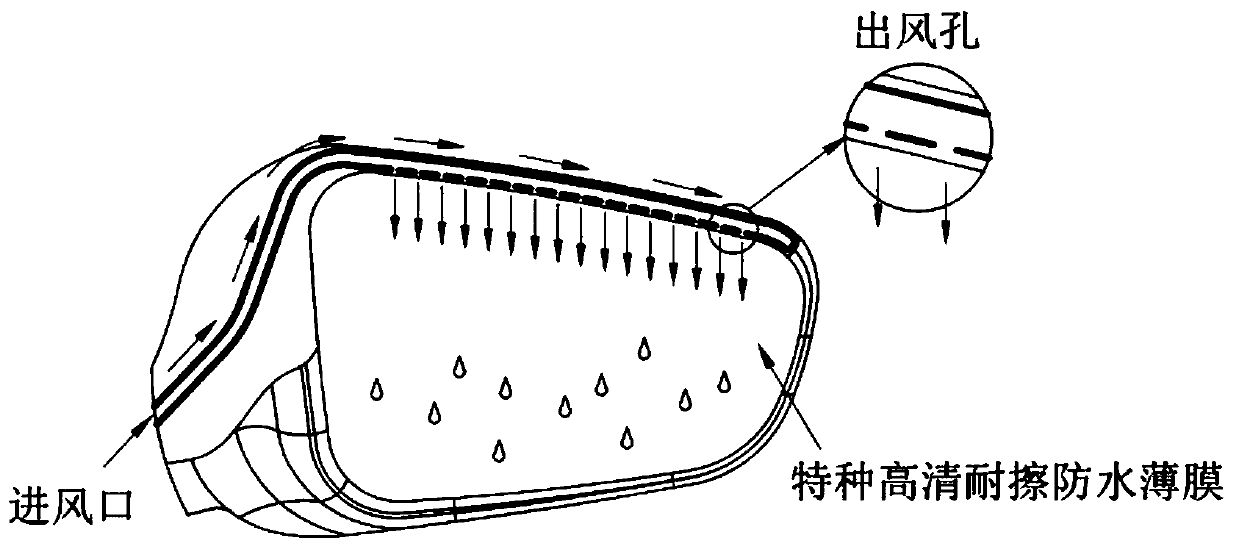

A technology of optical glass and film, which is applied in optics, optical components, instruments, etc., can solve problems such as car crashes easily, and achieve the effect of improving anti-wiping performance, high-definition film surface, and good water removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

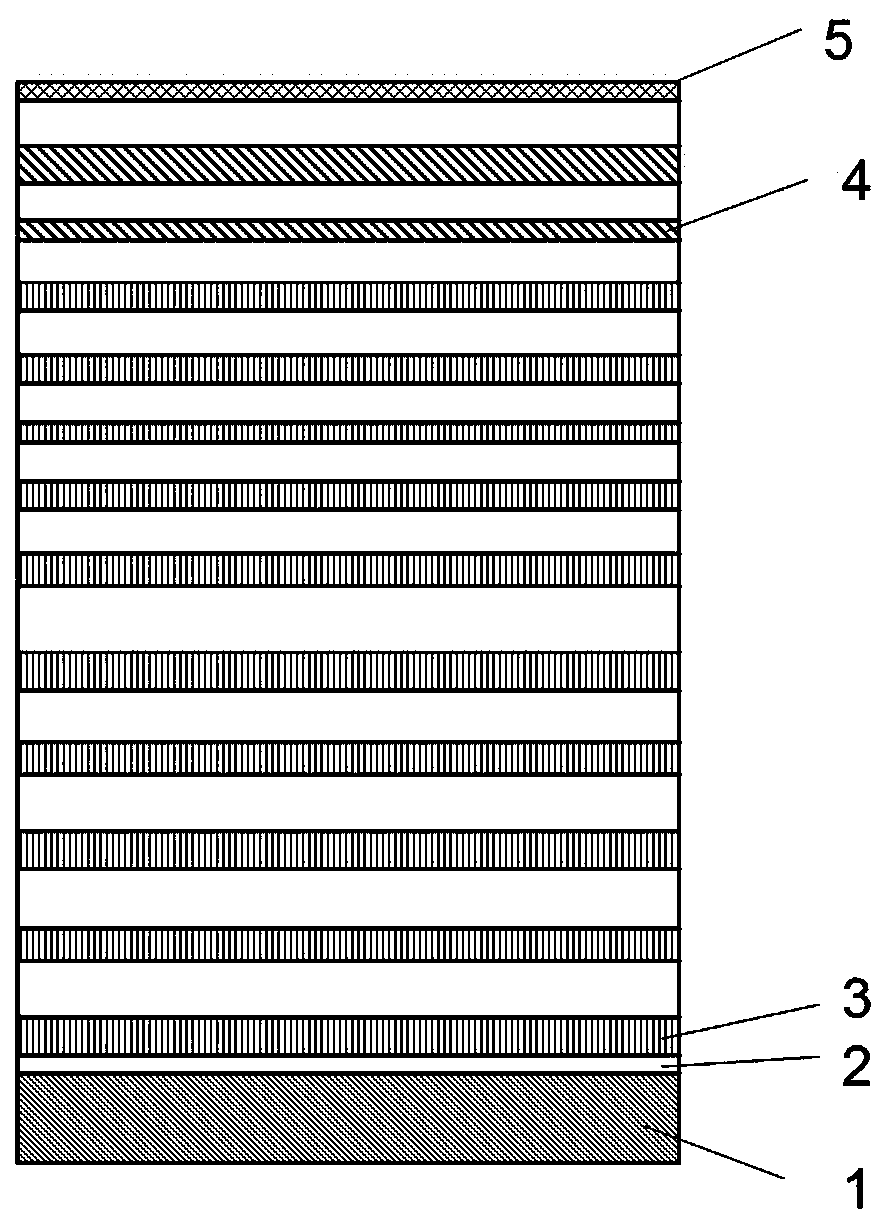

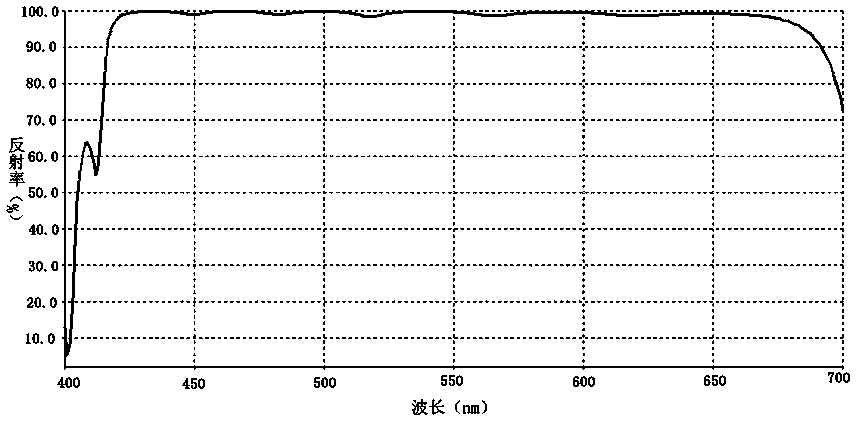

[0030]A high-definition scratch-resistant and waterproof optical glass film, which sequentially includes a base layer (glass), SiO 2 layer (36.5nm), Ti 3 o 5 layer (75.10nm), SiO 2 layer (103.50nm), Ti 3 o 5 layer (62.00nm), SiO 2 layer (106.95nm), Ti 3 o 5 layer (73.21nm), SiO 2 layer (103.15nm), Ti 3 o 5 layer (60.25nm), SiO 2 layer (100.15nm), Ti 3 o 5 layer (71.10nm), SiO 2 layer (108.85nm), Ti 3 o 5 layer (59.00nm), SiO 2 layer (90.58nm), Ti 3 o 5 layer (50.55nm), SiO 2 layer (75.88nm), Ti 3 o 5 layer (43.00nm), SiO 2 layer (80.55nm), Ti 3 o 5 layer (50.68nm), SiO 2 layer (88.15nm), Ti 3 o 5 layer (52.00nm), SiO 2 layer (84.40nm), ZrO 2 layer (45.00nm), SiO 2 layer (70.5nm), ZrO 2 layer (61.7nm), SiO 2 layer (85.00nm) and waterproof layer (33.00nm).

Embodiment 2

[0032] A high-definition scratch-resistant and waterproof optical glass film, which sequentially includes a base layer (glass), SiO 2 layer (40.0nm), Ti 3 o 5 layer (76.00nm), SiO 2 layer (104.12nm), Ti 3 o 5 layer (63.25nm), SiO 2 layer (108.21nm), Ti 3 o 5 layer (73.68nm), SiO 2 layer (104.75nm), Ti 3 o 5 layer (61.03nm), SiO 2 layer (100.89nm), Ti 3 o 5 layer (71.88nm), SiO 2 layer (110.50nm), Ti 3 o 5 layer (60.10nm), SiO 2 layer (92.15nm), Ti 3 o 5 layer (52.15nm), SiO 2 layer (77.32nm), Ti 3 o 5 layer (43.98nm), SiO 2 layer (82.15nm), Ti 3 o 5 layer (52.15nm), SiO 2 layer (90.00nm), Ti 3 o 5 layer (53.10nm), SiO 2 layer (85.12nm), ZrO 2 layer (57.50nm), SiO 2 layer (71.23nm), ZrO 2 layer (66.15nm), SiO 2 layer (83.88nm) and waterproof layer (36.00nm).

Embodiment 3

[0034] A high-definition scratch-resistant and waterproof optical glass film, which sequentially includes a base layer (glass), SiO 2 layer (39.73nm), Ti 3 o 5 layer (75.28nm), SiO 2 layer (103.96nm), Ti 3 o 5 layer (62.26nm), SiO 2 layer (107.13nm), Ti 3 o 5 layer (73.31nm), SiO 2 layer (103.27nm), Ti 3 o 5 layer (60.37nm), SiO 2 layer (100.35nm), Ti 3 o 5 layer (71.28nm), SiO 2 layer (110.20nm), Ti 3 o 5 layer (59.20nm), SiO 2 layer (91.87nm), Ti 3 o 5 layer (51.47nm), SiO 2 layer (76.97nm), Ti 3 o 5 layer (43.44nm), SiO 2 layer (81.29nm), Ti 3 o 5 layer (51.84nm), SiO 2 layer (89.18nm), Ti 3 o 5 layer (52.55nm), SiO 2 layer (84.46nm), ZrO 2 layer (42.07nm), SiO 2 layer (73.58nm), ZrO 2 layer (77.59nm), SiO 2 layer (82.36nm) and waterproof layer (35.8nm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com