Rolling-type quantitative dyeing device

A kind of dyeing equipment and rolling technology, which is applied in the field of textile printing and dyeing, can solve the problems of waste of dye liquor, inaccurate ratio of dye liquor to fabric, poor fabric dyeing quality, etc., to improve uniformity, improve ratio accuracy, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The embodiments are described below with reference to the accompanying drawings. The embodiments shown below do not limit the invention content described in the claims. required for the solution.

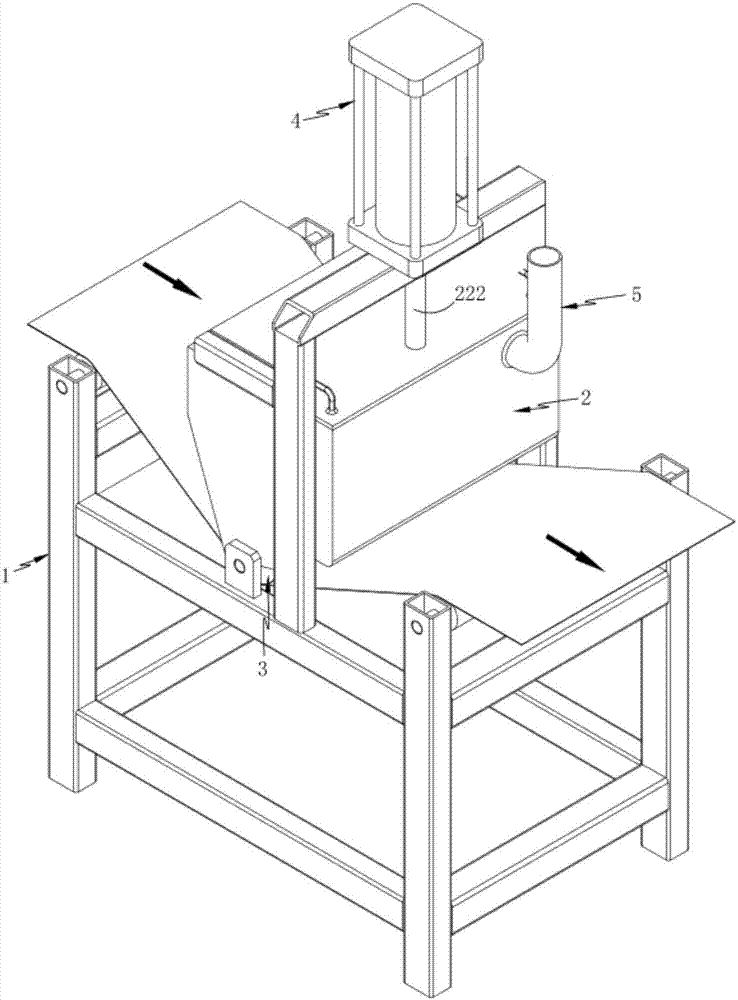

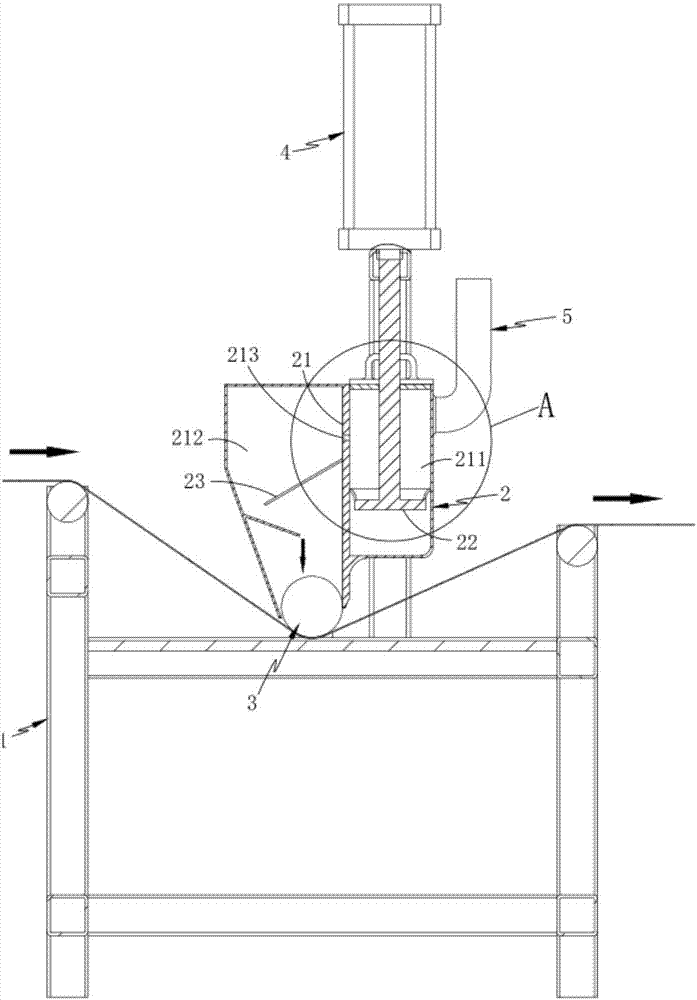

[0032] Such as figure 1 As shown, a rolling quantitative dyeing equipment includes a frame 1, a dye liquor bin 2 fixedly installed on the rack 1, a dyeing roller 3 rotatably installed at the bottom of the dye liquor bin 2, and a dye liquor bin fixedly installed on the dye liquor The power mechanism 4 at the top of the bin 2 and the infusion tube 5 arranged on the side of the dye liquor bin 2 and communicated with the interior thereof, the dye liquor bin 2 includes:

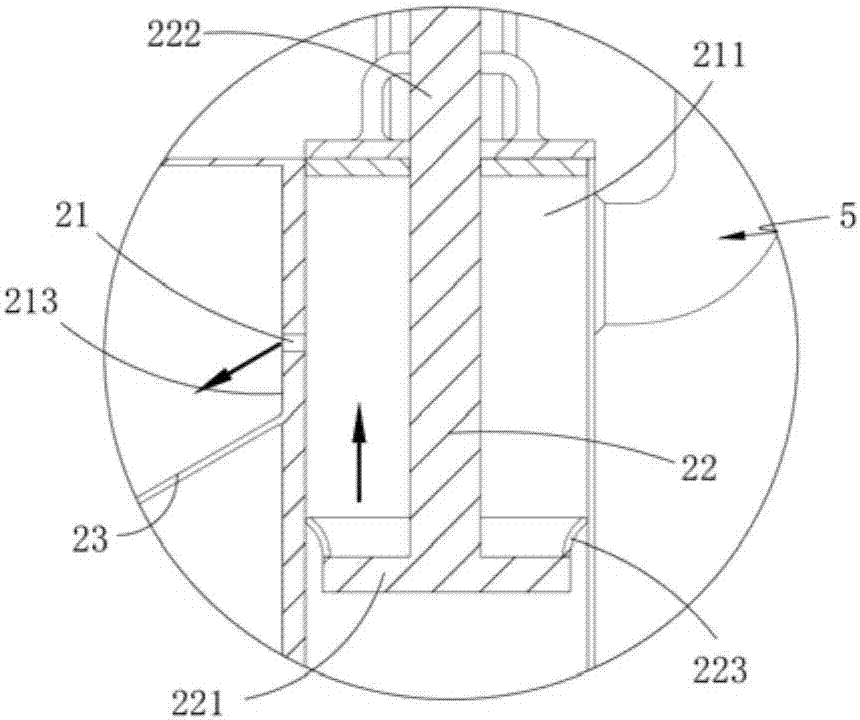

[0033] A partition 21, the partition 21 is located inside the dye solution bin 2, and its two sides respectively form a storage bin 211 and a dyeing bin 212; The dye solution passage 213 of 212; the dye solution is in the waiting bin 211, and the quantitative dye solution delivery is carried out by the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com