Casting production equipment capable of degrading seedling cultivation boxes and manufacturing process thereof

A technology for production equipment and seedlings, which is applied in the field of cast production equipment and its manufacturing process, can solve the problems of substandard degradation performance of agricultural seedling film, difficulty in ensuring the accuracy of proportioning, poor quality of cast film, etc., and achieve faster adhesion and compounding. Specific efficiency, accurate proportioning, and the effect of increasing the softening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

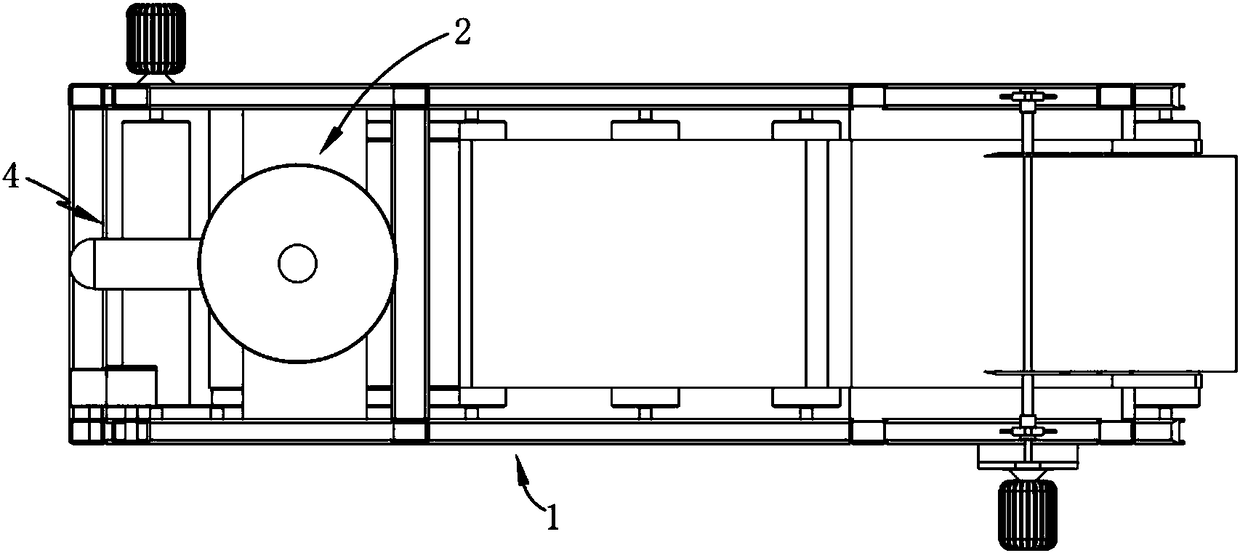

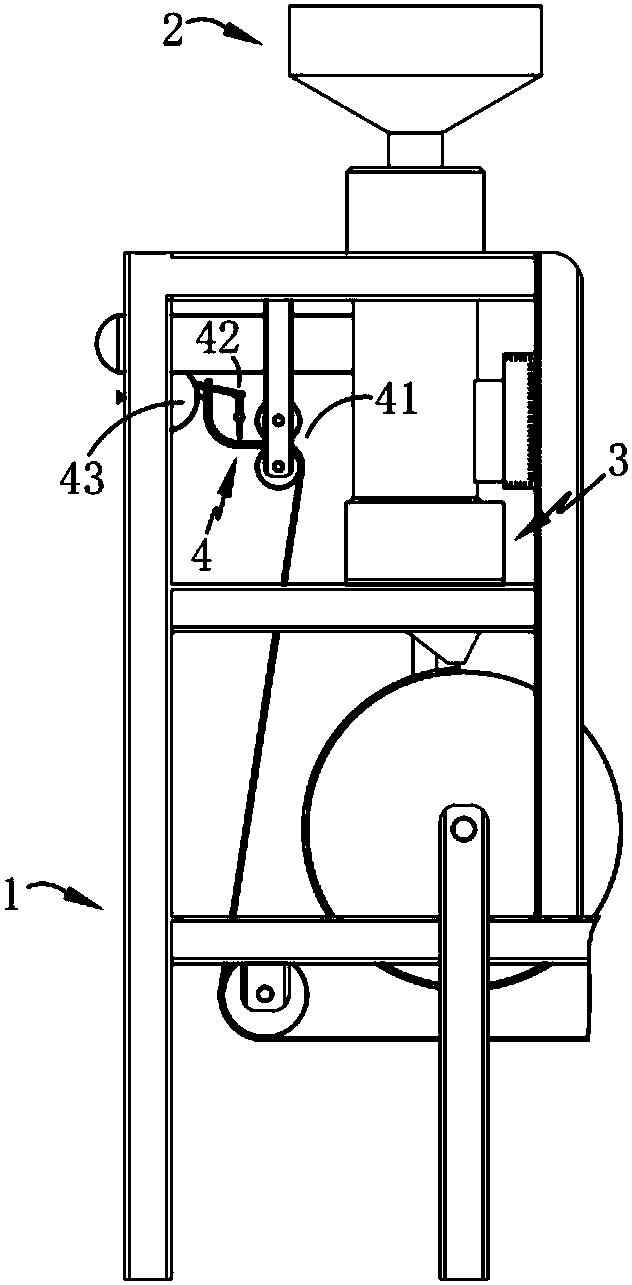

[0041] Such as figure 1 , 2 , 3, 4 and 5, the casting production equipment and manufacturing process of the degradable seedling cultivation box include a frame 1, a storage bin 2 arranged on the frame 1 for storing new materials, and a The interior of the warehouse 2 is connected to the melting mechanism 3 for melting and liquefying the new material, and also includes:

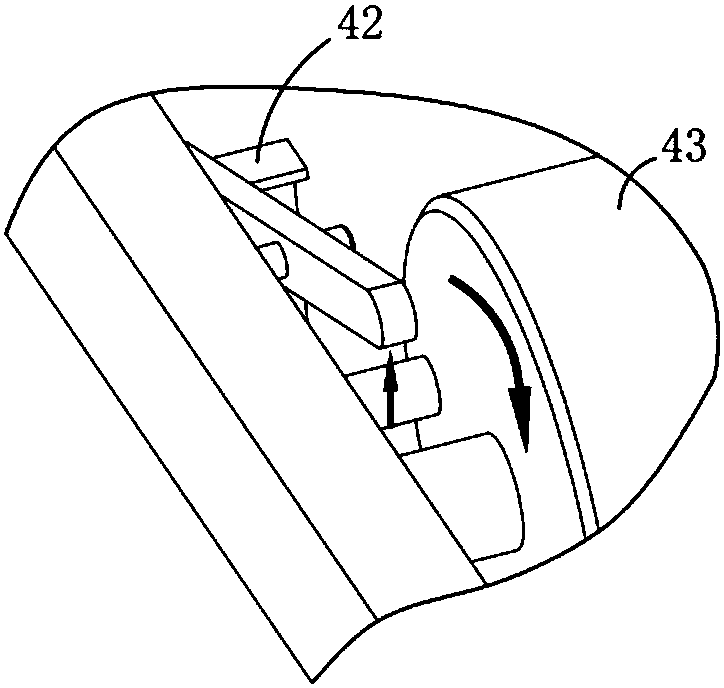

[0042]Cutting transmission mechanism 4, described cutting transmission mechanism 4 comprises the transmission component 41 that is arranged on described frame ...

Embodiment 2

[0053] Such as Figure 4 with 5 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The feature is that: the batching assembly 52 is arranged above the melting mechanism 3 and communicated with its interior, it includes a conveying pipe 521 communicated with the feeding assembly 51 and is arranged in the conveying pipe 521 and communicated with the feeding pipe 521. The guide part 522 opposite to the assembly 51 forms a blanking area 523 between the guide part 522 and the conveying pipe 521; the trim section is transported into the conveying pipe 521 through the transfer assembly 43, and the trim is transported by the internal directional airflow. At the same time when the section is conveyed to the preheating zone 53, the airf...

Embodiment 3

[0057] According to the drawings in the manual Figure 9 Describe the tape casting manufacturing process of three kinds of degradable nursery stock cultivation box of embodiment:

[0058] The flow casting manufacturing process of the degradable seedling cultivation box includes the following parts:

[0059] (a) In the transmission part, the continuous edge material is oriented and transmitted by the transmission roller group 411 in a two-way clamping transmission mode, and is guided and transmitted by the guide plate 412 at the same time;

[0060] (b) segmented part, after the step (a) carries out directional transmission to the continuous edge material, the edge material is segmented and cut by the cutting assembly 42 in an equidistant intermittent manner;

[0061] (c) The transfer part, the side material section cut by step (b) is adsorbed and transferred to the feed assembly 51 through the transfer assembly 43 in a rotational manner, and the side material is entrusted by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com