Safe sedimentation construction method of sand-free precipitation tube well

A construction method and the technology of the downpipe, which are applied in the basic structure engineering, construction and other directions, can solve the problems of low operation safety, collapse and damage of the well pipe, detachment of the well pipe section, etc., so as to improve the safety performance, the process principle is simple, the Stable and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

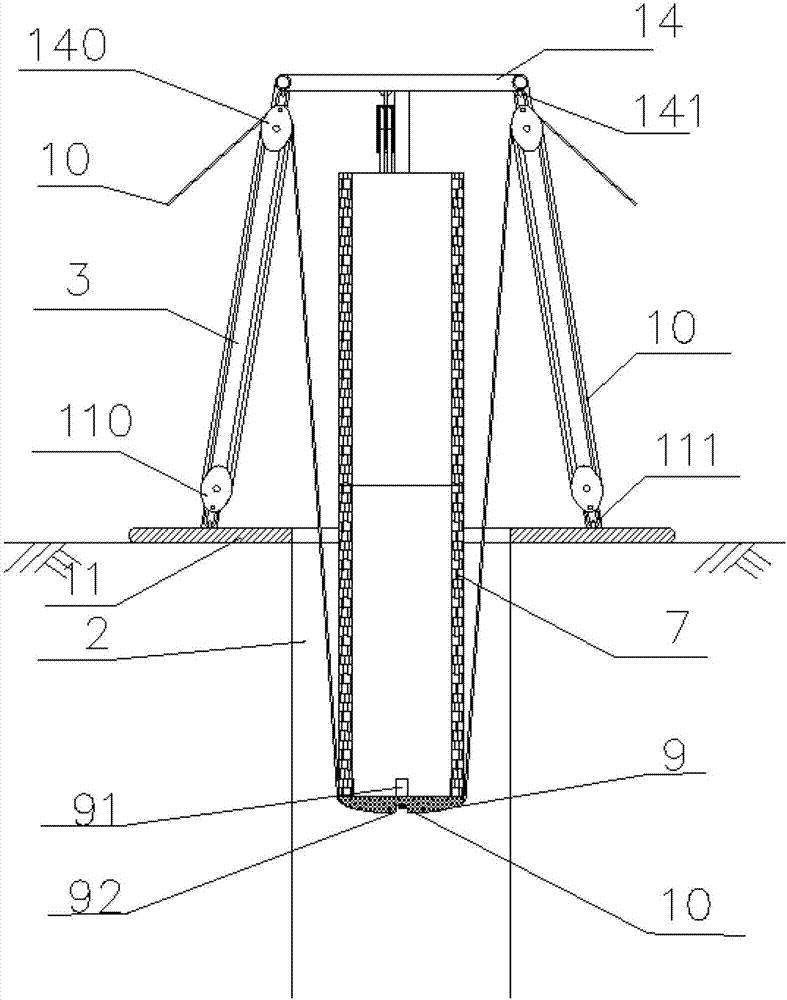

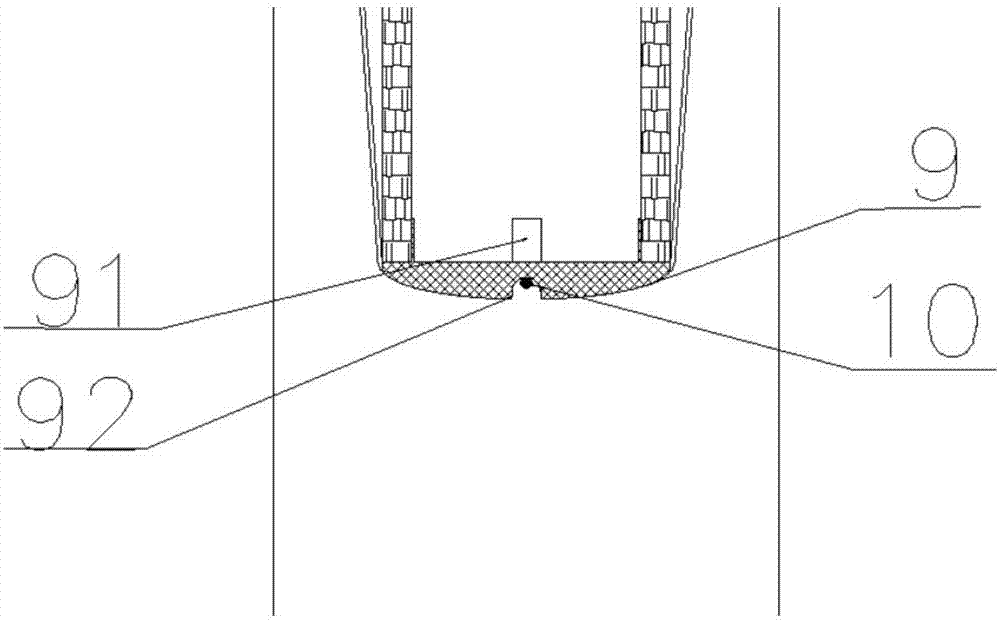

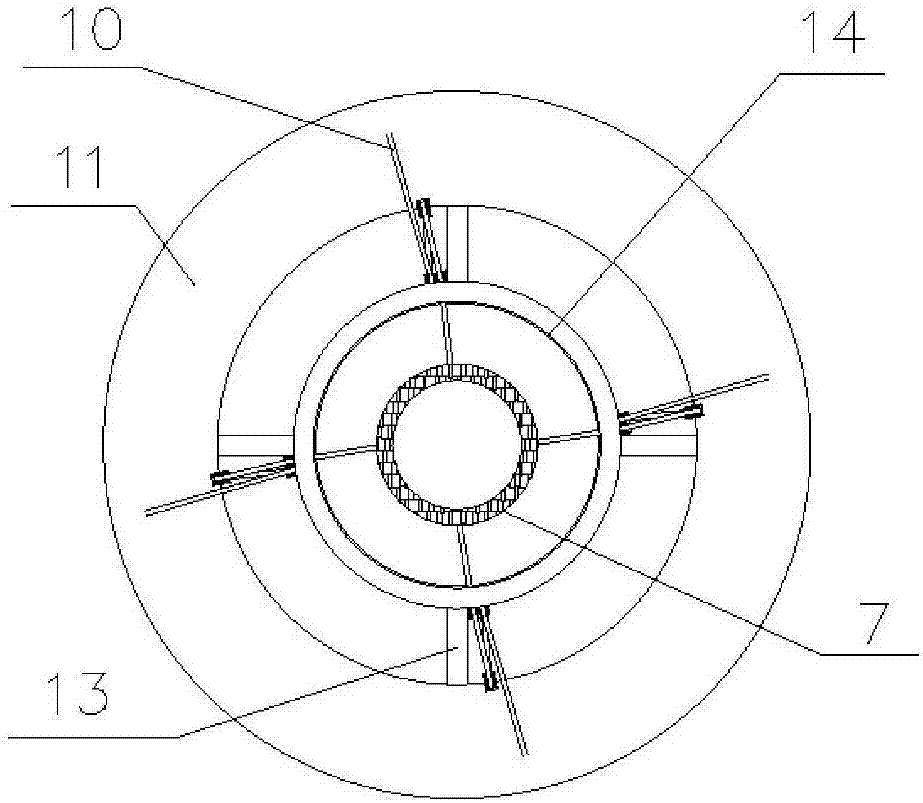

[0041] refer to Figure 1-16 , The support frame 1 that this sand-free downcomer well safety sinking construction method adopts comprises base 11, support rod 13, load-bearing top ring 14, single pulley 110, double pulley 140, and coordinating device comprises bottom drag cover plate 9.

[0042]Step S1, install the support frame before the operation, the support frame includes a base 11 with a circular cross-section, four support rods 13, and a load-bearing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com