Water-saving and gas-venting closestool

A toilet and exhaust cap technology, applied in the field of "water-saving exhaust toilet, can solve the problems of wasting water resources, poor deodorization effect, etc., and achieve the effect of saving water, simple and easy manufacturing process, and maintaining air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

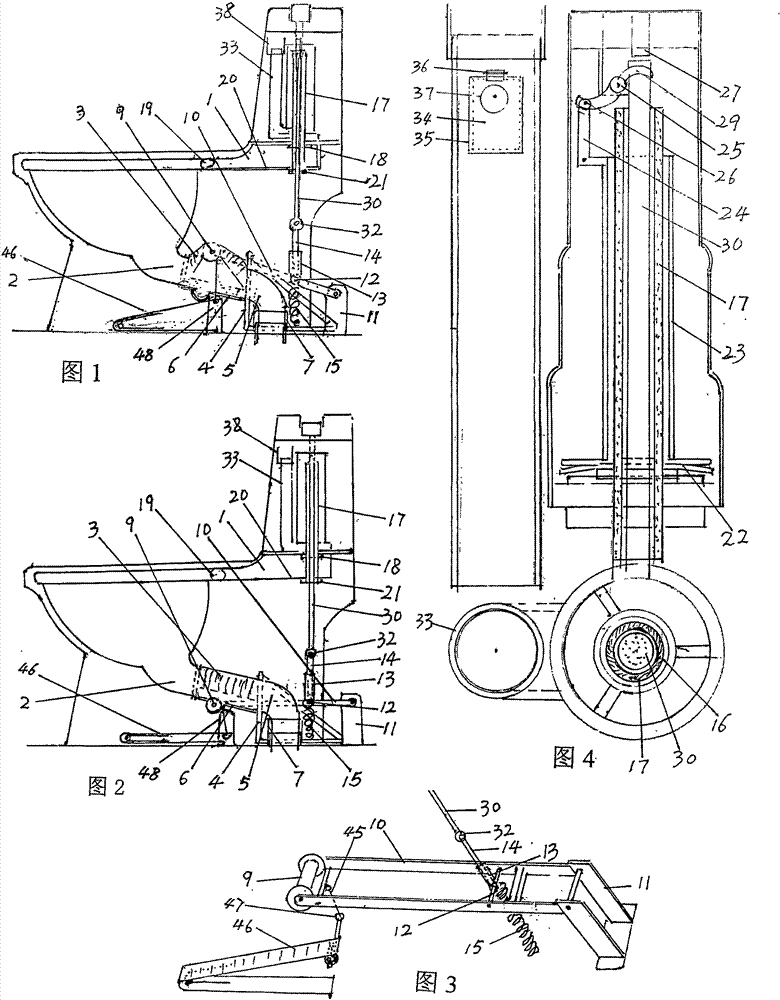

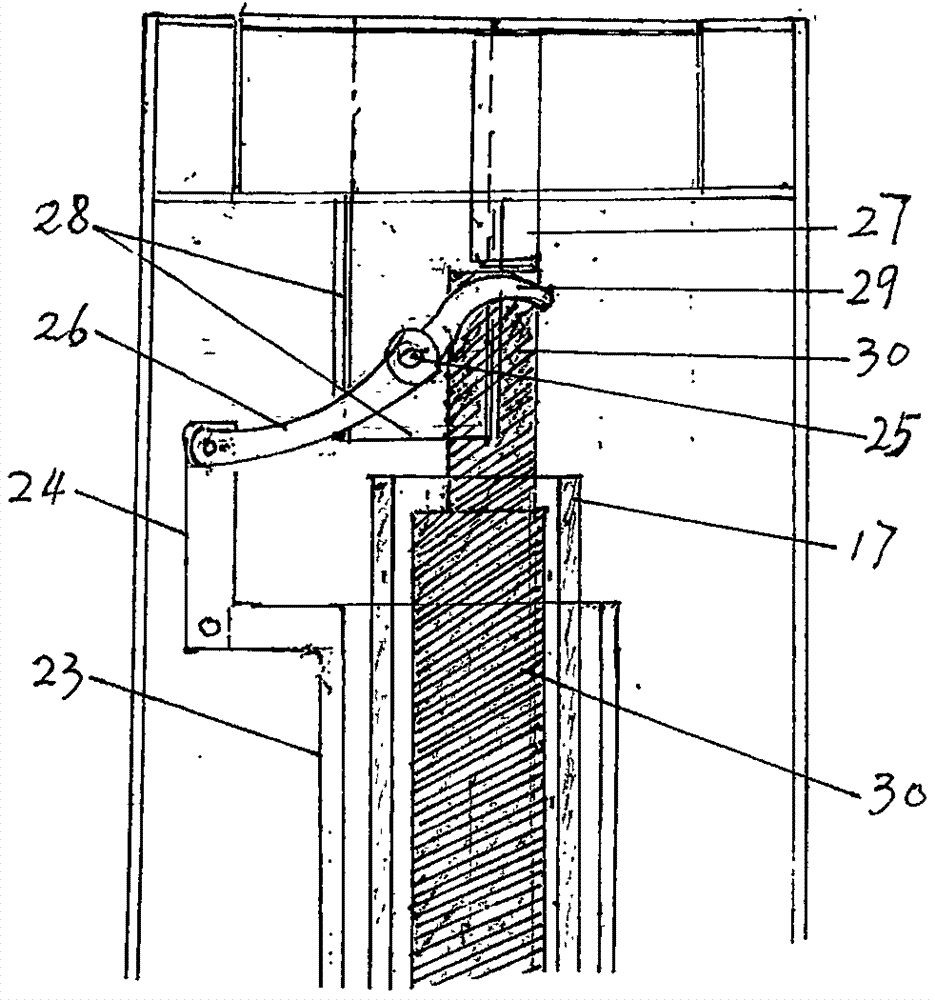

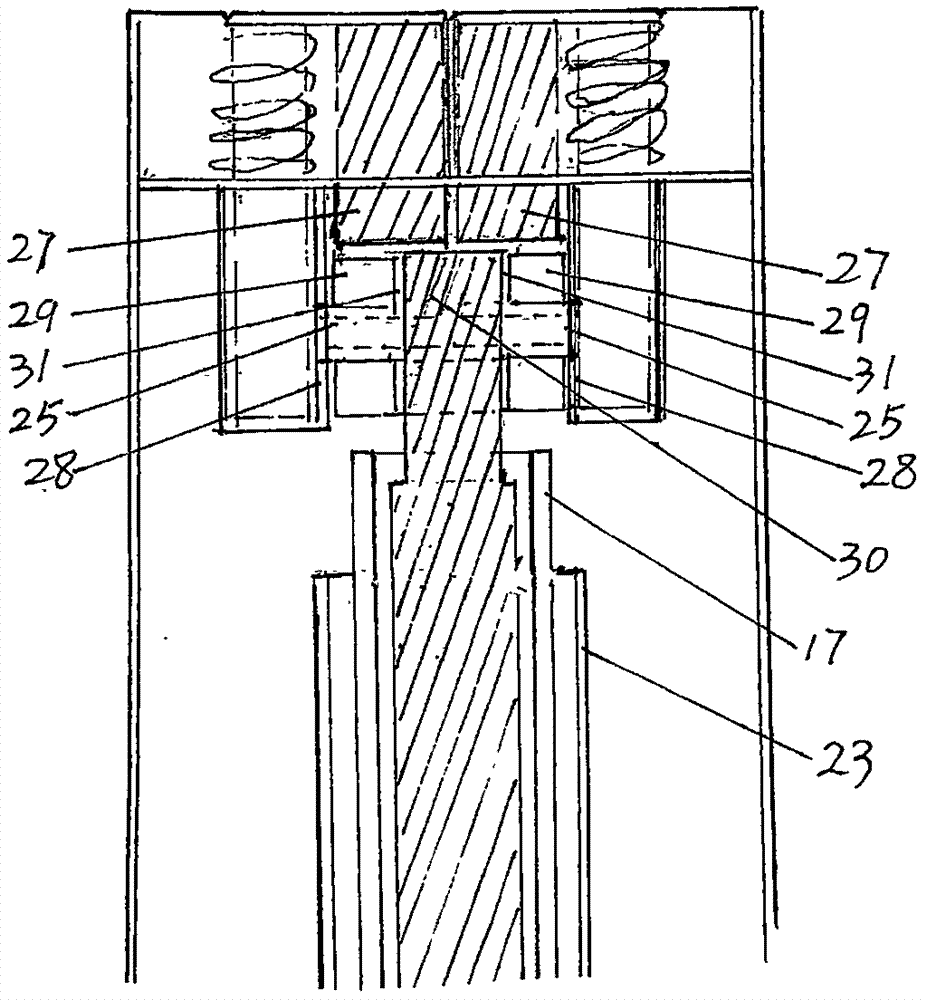

[0026] In Figure 1 and Figure 2, only the water outlet of the toilet is equipped with an internal water outlet pipe 1, and a section of sewage discharge pipe 2 is bent directly backward and downward from the concave point at the bottom of the toilet, and a section of inner wall is sleeved on the pipe mouth. The durable rubber hose 3 has several arc-shaped rubber corrugations on the upper half of the hose. The rear end of the hose is sleeved on the elbow 5 positioned by the tripod 4. There is a groove-shaped slide plate support 6 under the hose. The lower end of the elbow is connected to the sewage pipe to guide the sewage In the mouth of the pit, there is a section of outer casing 7 that can be fastened at both ends. The lower end is set on the mouth of the sewage pit 8 to close, and the upper end is closed with the outer periphery of the sewage pipe. In Fig. 1, Fig. 2, and Fig. 3, a The shaft roller 9 for lifting the rubber hose, and the two frames at the rear end of the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com