A gearbox shaft locking structure

A technology of locking structure and gearbox, applied in the field of gearbox, can solve the problems of complex structure, large space for parking gear, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

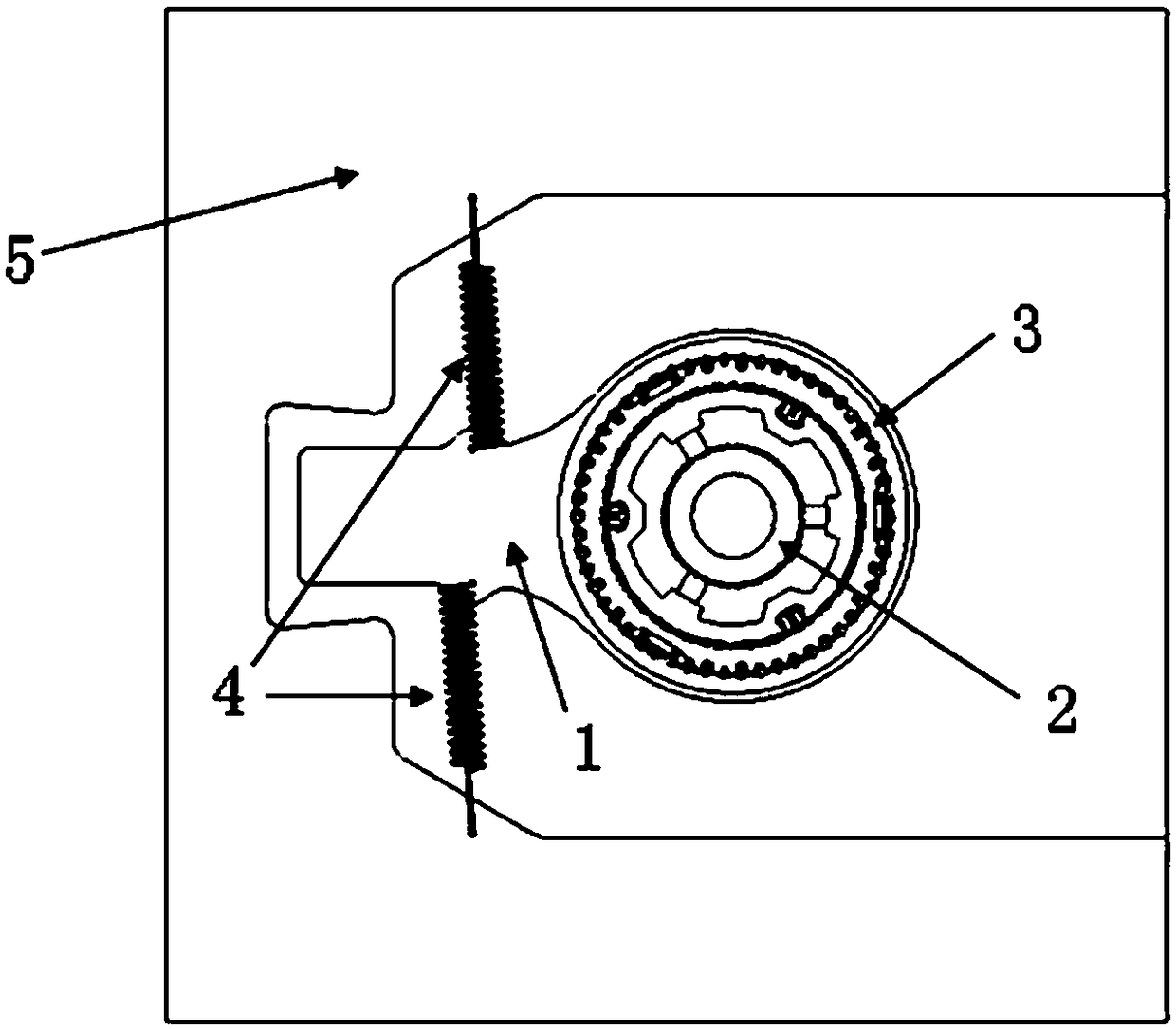

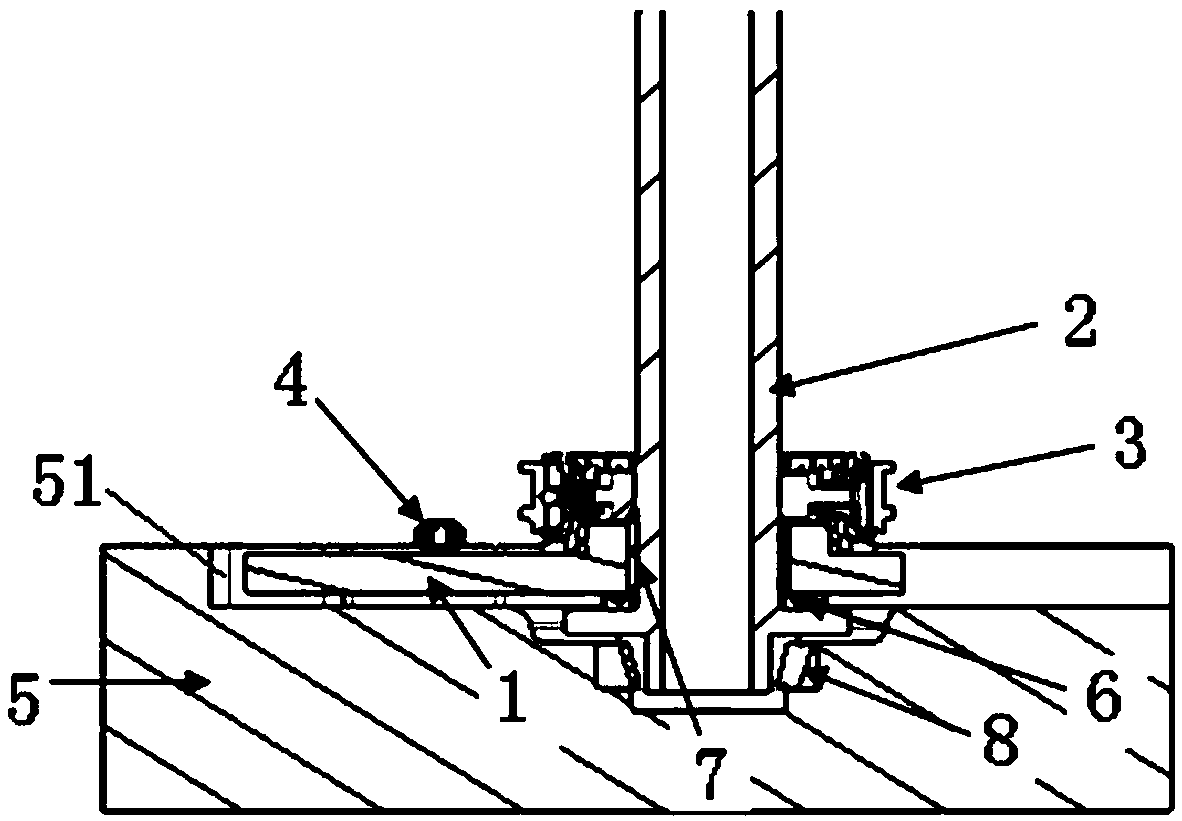

[0031] This application uses synchronous shifting combined with teeth to realize the selection of the locking gear. The locking wheel is a swing arm structure, and the mechanical locking within a small angle can be realized by means of the structure of the gearbox housing. , The locking wheel is relatively static or returned by the return spring.

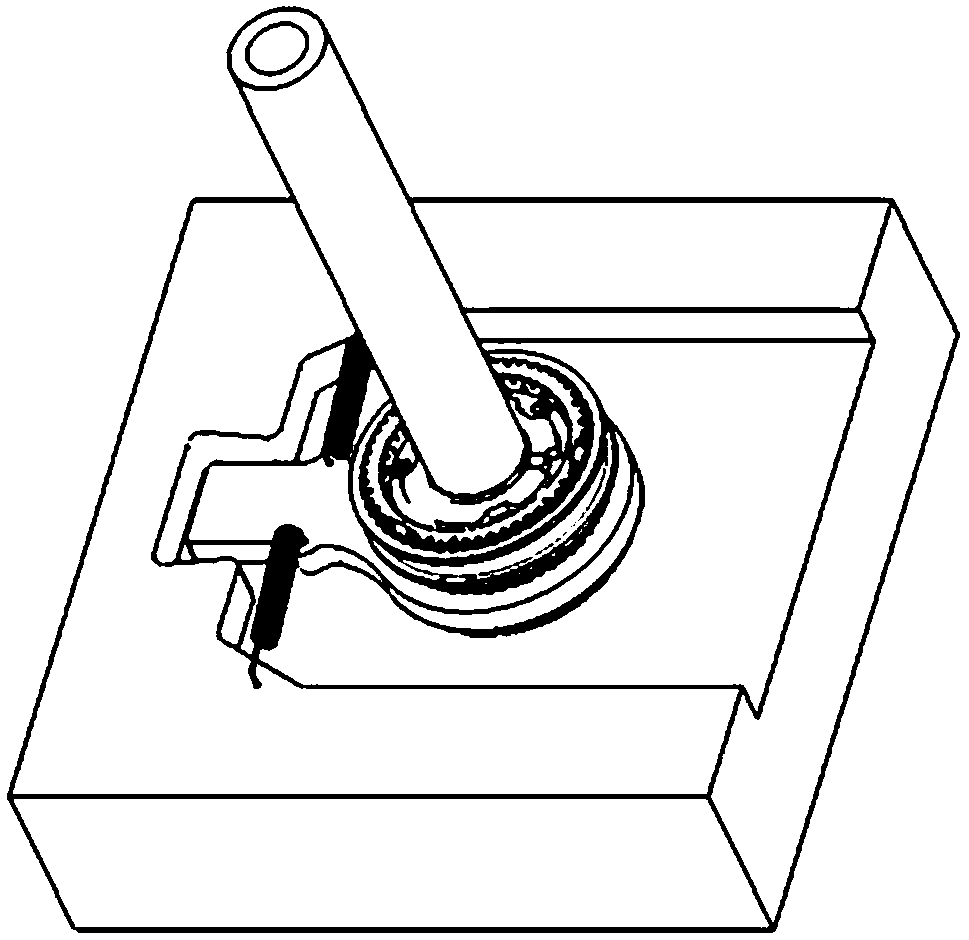

[0032] Such as figure 1 with figure 2 As shown, the gearbox shaft locking structure of the present application includes a gearbox case 5, a locking wheel 1, a gear shaft 2, a synchronizer assembly 3, and two return springs 4, wherein the gearbox case is the entire transmission Part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com