Three-position disconnecting switch for locomotive and use method thereof

An isolating switch and three-position technology, which is applied in the direction of electric switches, air switch parts, power devices inside the switch, etc., can solve the problems that cannot be completely eliminated, such as misoperation and poor safety, so as to facilitate maintenance and ensure the safety of power supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

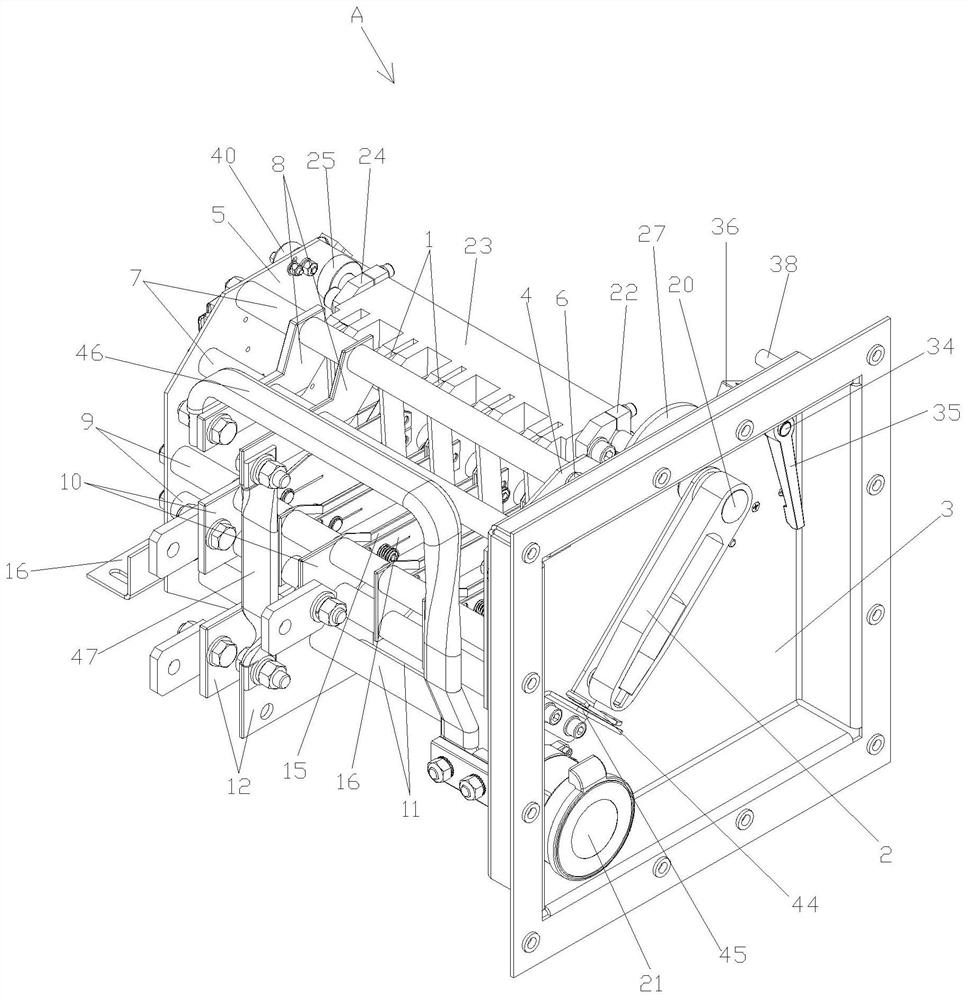

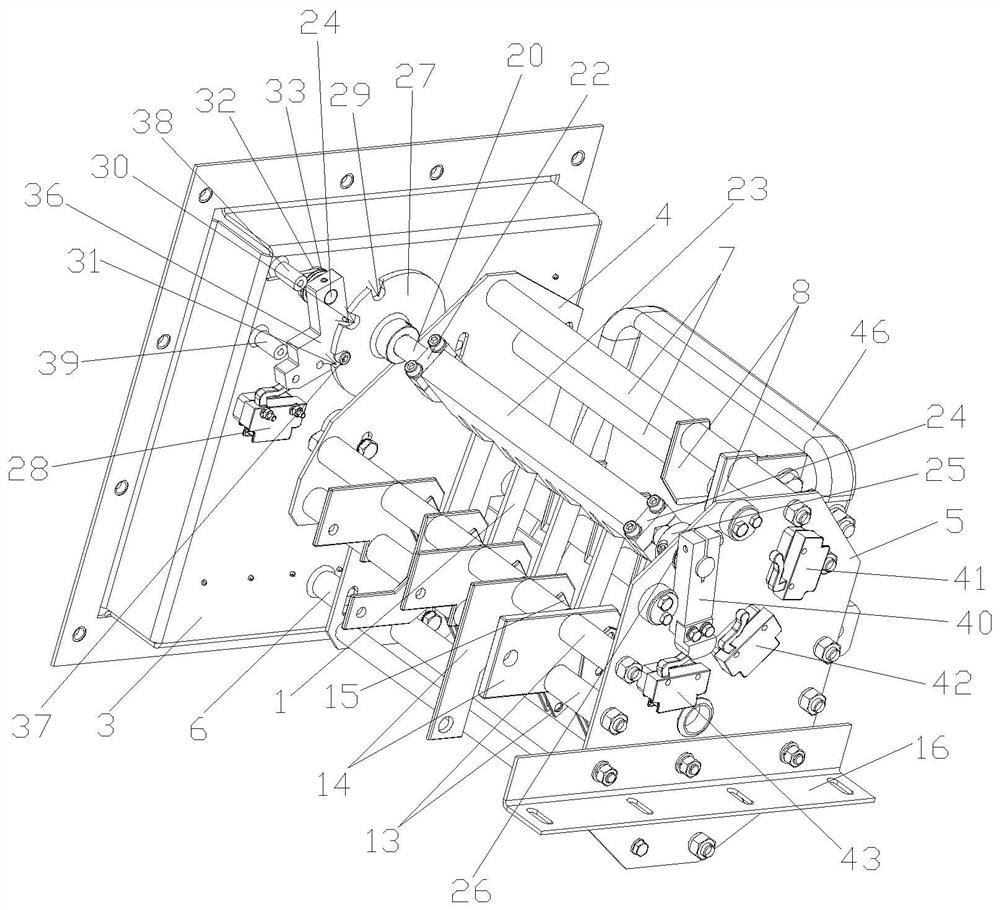

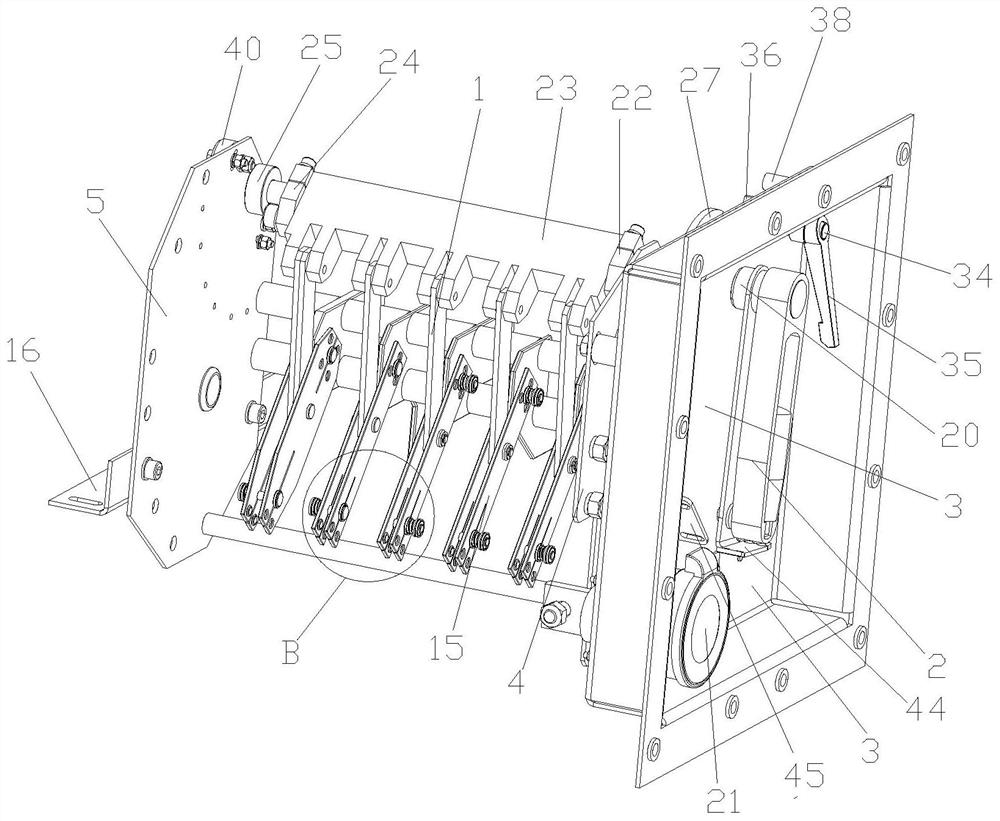

[0080] like figure 1 As shown, a three-position isolating switch for a locomotive according to the present invention includes

[0081] The first incoming line position is used to strobe the power supply line of the workshop power supply to the line position;

[0082] The second incoming line position is used to select the line that is grounded at the outgoing line position;

[0083] The third incoming line position is used to select the line that the pantograph supplies power to the line position;

[0084] The operating mechanism is used to drive the isolation knife assembly to rotate so that the outgoing wire position is connected to the first wire incoming position, the second incoming wire position or the third incoming wire position;

[0085] a detector, configured to detect the conduction signal of the first incoming line position, the second incoming line position or the third incoming line position;

[0086] The frame body is used for installing the first wire inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com