Photovoltaic assembly, photovoltaic tile and photovoltaic system of building roof

A photovoltaic module and tile technology, applied in the field of solar energy, can solve the problems of inability to guarantee waterproof performance, aging of glue joints, low power generation, etc., and achieve the effect of reducing the utilization rate of air conditioners, reducing the overall temperature of the roof, and improving the power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

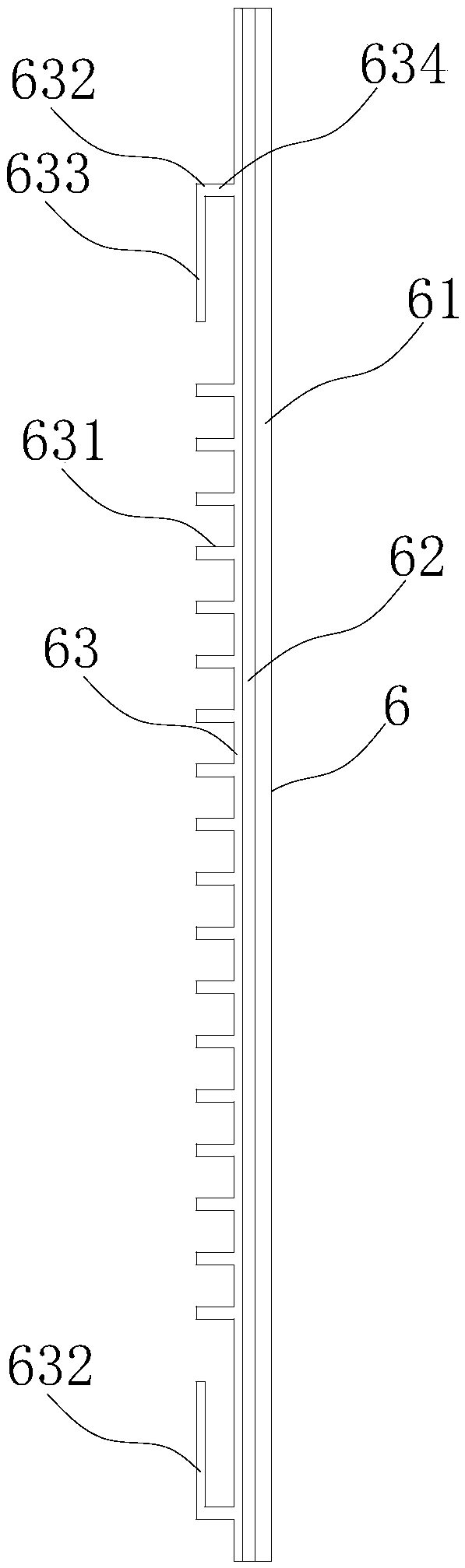

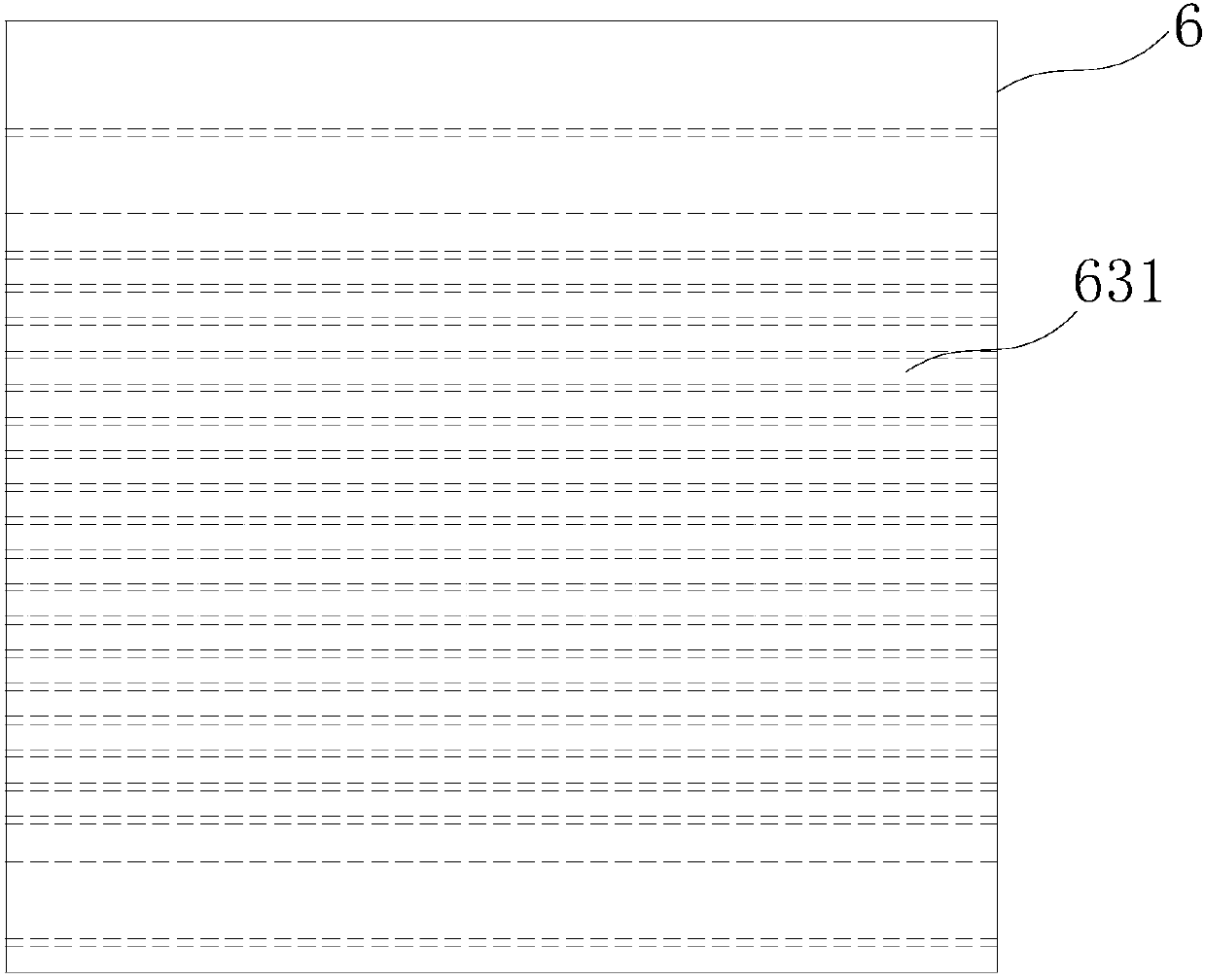

[0032] like figure 1 and figure 2 As shown, the present embodiment is a photovoltaic module 6 , which includes a pressed glass plate 61 , battery sheets 62 and a back plate 63 , and a plurality of cooling ribs 631 are arranged on the back plate 63 . In this embodiment, the backboard 63 is an aluminum backboard, and the glass plate 61 is a coated tempered glass plate. The coated toughened glass plate on the upper surface ensures the strength of the upper surface of the photovoltaic module 6 of this embodiment, improves its compression resistance, fire resistance and anti-hail ability, and the aluminum back plate replaces the existing conventional glass or polymer material back plate, which plays a role Reduce material costs, improve thermal conductivity and heat dissipation performance.

[0033] In this embodiment, the heat dissipation fins 631 are arranged on the back plate 63 to dissipate heat. The heat dissipation fins 631 increase the contact area between the photovoltai...

Embodiment 2

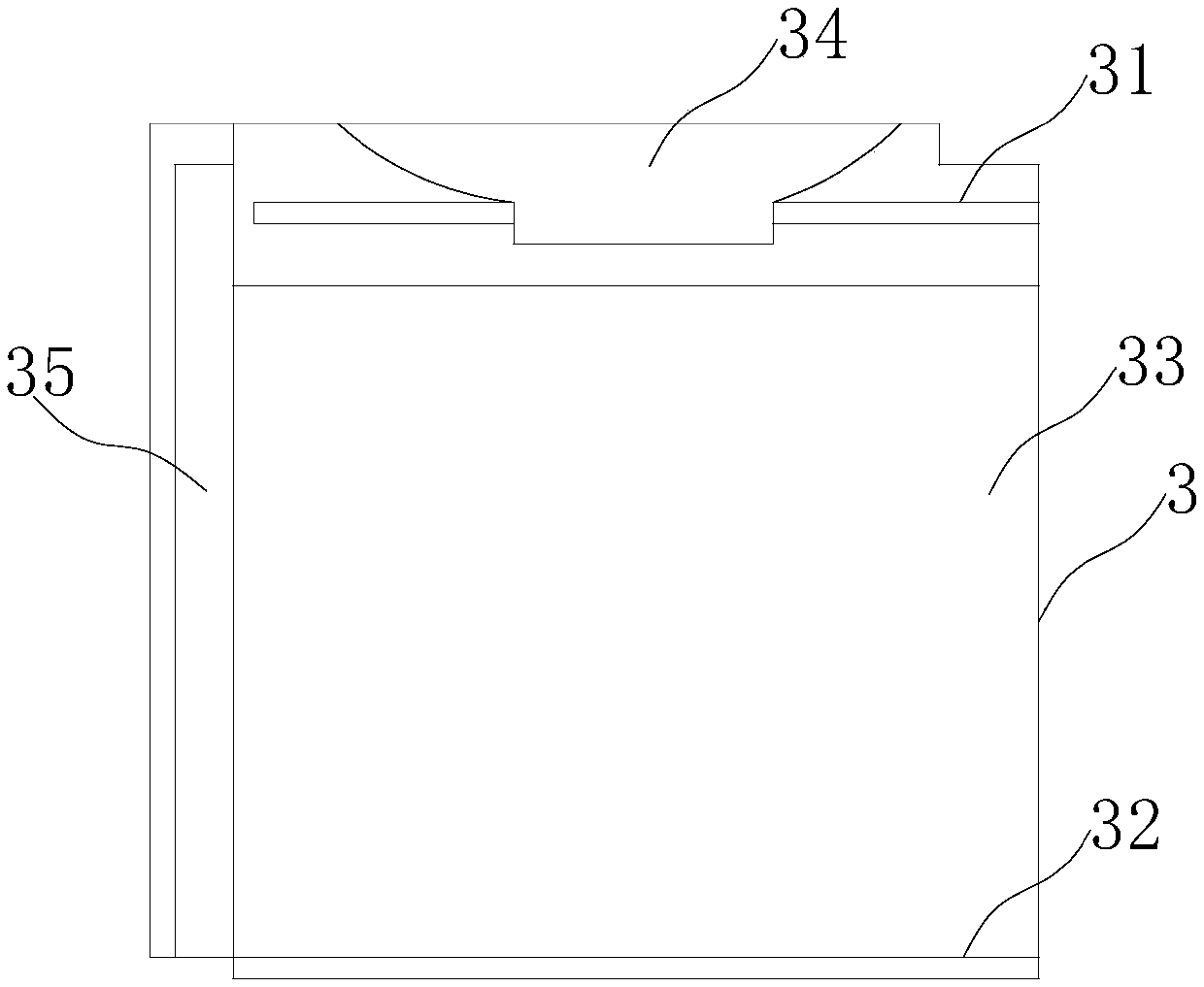

[0036] like Figure 3 ~ Figure 5 As shown, this embodiment is a photovoltaic tile for installing the above-mentioned photovoltaic module 6, including a tile base 3, and an upper rib 31, a lower rib 32, and an upper rib 32 are arranged on the tile base 3. The positioning groove 33 between the rib 31 and the lower rib 32, the upper rib 31 and the lower rib 32 are arranged in parallel, the horizontal support part 633 of the support member 632 is fixedly connected with the bottom of the positioning groove 33, and the photovoltaic module 6 Both ends are abutted between the upper rib 31 and the lower rib 32 . In this embodiment, the bottom of the photovoltaic module 6 is fixedly connected to the bottom of the positioning groove 33 through the horizontal support part 633, and the upper and lower ends of the photovoltaic module 6 are abutted between the upper rib 31 and the lower rib 32 to realize the alignment of the photovoltaic module 6. The fixing of the upper and lower positions...

Embodiment 3

[0040] like Image 6 and Figure 7 As shown, this embodiment is a photovoltaic module system on the roof of a building, including a water-slip strip 1 arranged on the roof of the building, a tile strip 2, a photovoltaic tile matched with the tile strip 2, and a photovoltaic module arranged on the photovoltaic tile. The photovoltaic tiles in this embodiment are the photovoltaic tiles in Embodiment 2, and the photovoltaic modules are the photovoltaic modules in Embodiment 1.

[0041] In this embodiment, the power system is connected to the left and right through the junction box. Since the junction box is below the upper battery assembly, this embodiment ensures that it will not be too much affected by rainwater and ensures the safety of power supply. At the same time, the left and right photovoltaic tiles overlap each other to ensure the waterproof problem in the left and right directions, and the left and right tiles are on the same plane to form a transverse cavity to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com