Lead fixing device and composite cross arm

A wire fixation and cross-arm technology, which is applied to the cable suspension device, cable space arrangement/configuration, etc., can solve the problems of easy breakage of the composite cross-arm, heavy maintenance workload, cumbersome wire binding process, etc., and reduce the project cost. Effects of maintenance cost, reduction of workload, reduction of material cost and process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solution of the present invention, a wire fixing device and a composite cross arm provided by the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

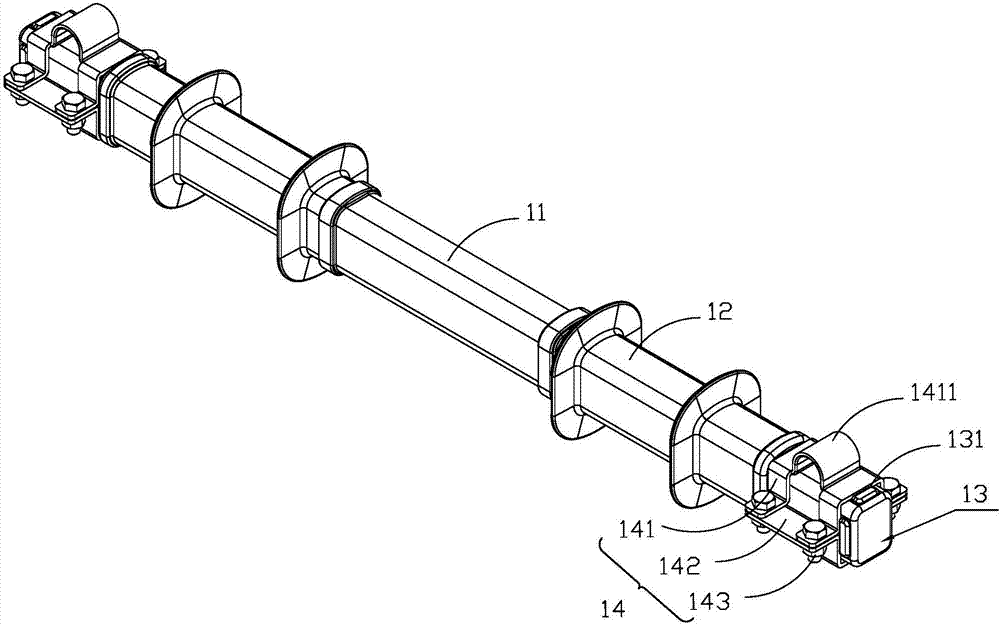

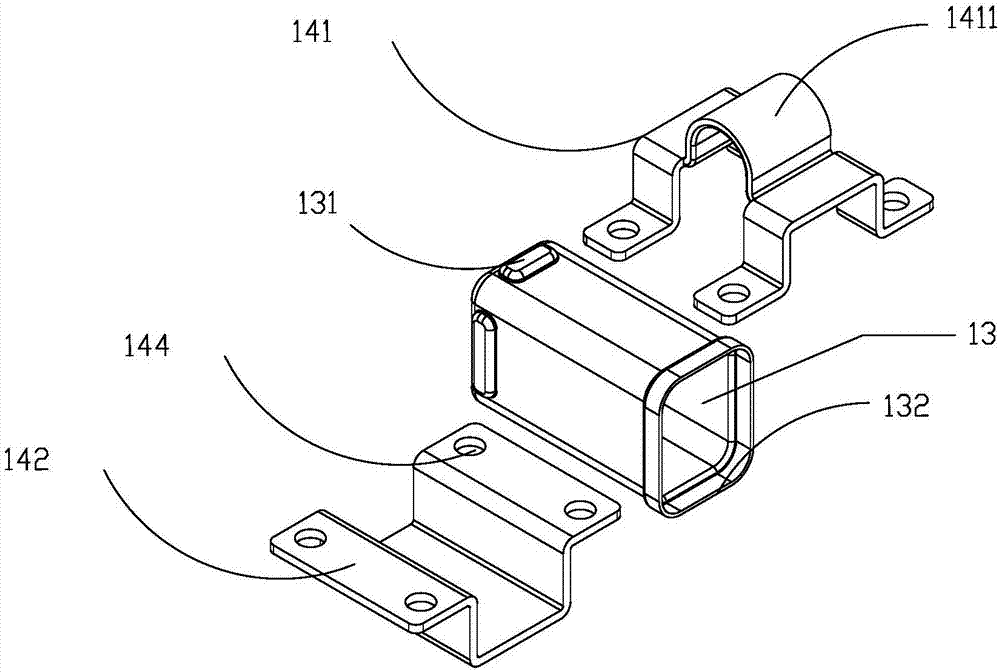

[0044] Such as figure 1 As shown, the first embodiment of the wire fixing device of the present invention is used to fix the wire on the composite cross arm. The composite cross arm includes an insulating core rod 11 and an insulating layer 12 covering the insulating core rod 11. The wire fixing device includes a cross arm connector 13 and a wire fixing member 14. The cross arm connector 13 is covered and fixed on the outer peripheral surface of the insulating core rod 11, and the cross arm connector 13 abuts against the insulating layer 12; the wire fixing member 14 is provided with In the wire slot 1411 for accommodating the wires, the wire fixing member 14 is fixed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com