Ball of small-leaf holly leaves and processing technique

A small-leaf kudingqiu tea and processing technology, applied in the field of tea processing, can solve problems such as loss of tea color, customer satisfaction, and affecting tea quality, and achieve the effect of ensuring tea quality, ensuring uniformity, and facilitating uniform frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

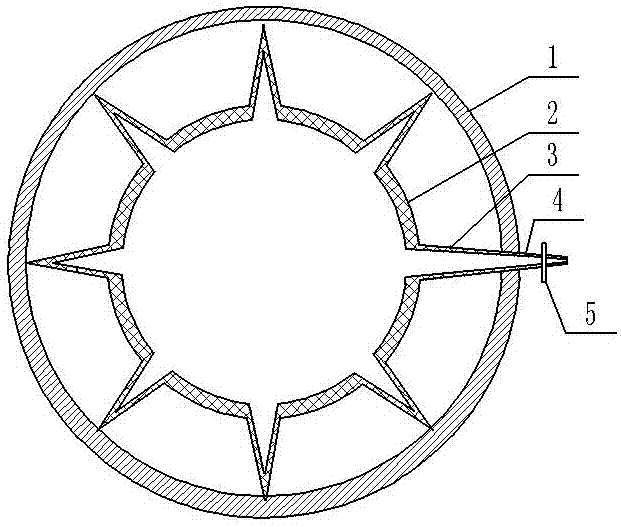

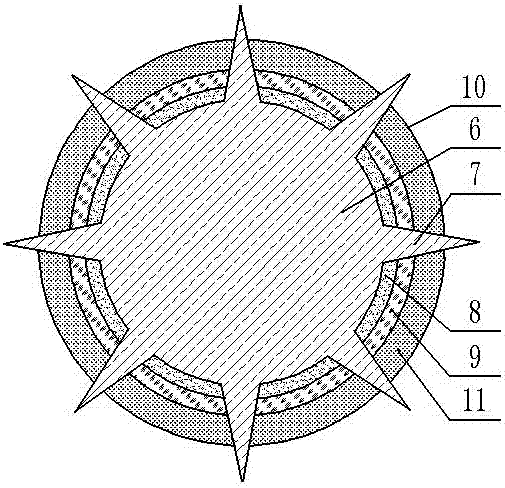

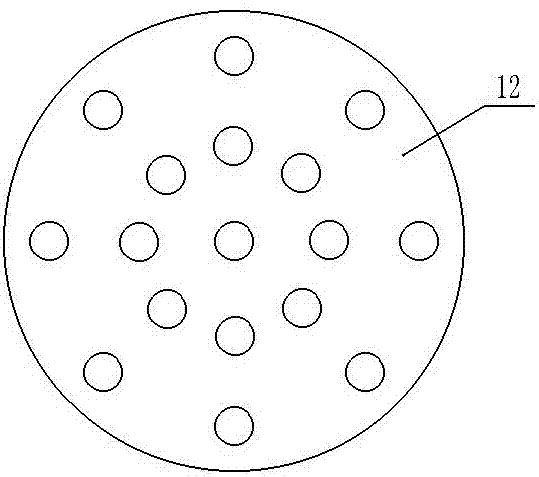

[0022] The reference signs in the drawings of the description include: first hollow ball 1, second hollow ball 2, through pipe 3, filling port 4, valve 5, ice ball 6, acupuncture part 7, honey layer 8, tea leaf layer 9, tea Ball 10, packaging layer 11, ball tea 12.

[0023] A small-leaf Kuding ball tea, such as image 3 As shown, the tea ball 12 has a hollow structure and has a porous surface. Such a structure, on the one hand, is conducive to the outward distribution of water in the tea ball 10, preventing the tea leaves from discoloration and deterioration due to water accumulation during processing; When the tea ball 12 is used to make tea, water flows into the tea ball 12 through the hole, which is beneficial to the full brewing of the tea leaves, so that a large amount of beneficial substances in the tea leaves flow out, which is convenient for the human body to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com