Processing equipment for processing workpieces in a depressurized space

A processing device and a technology for processed objects, which are applied to workbenches, manufacturing tools, electrical components, etc., can solve problems such as low precision, and achieve the effects of improving conveying precision and suppressing relative movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]Hereinafter, various embodiments will be described in detail with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same or equivalent part in each drawing.

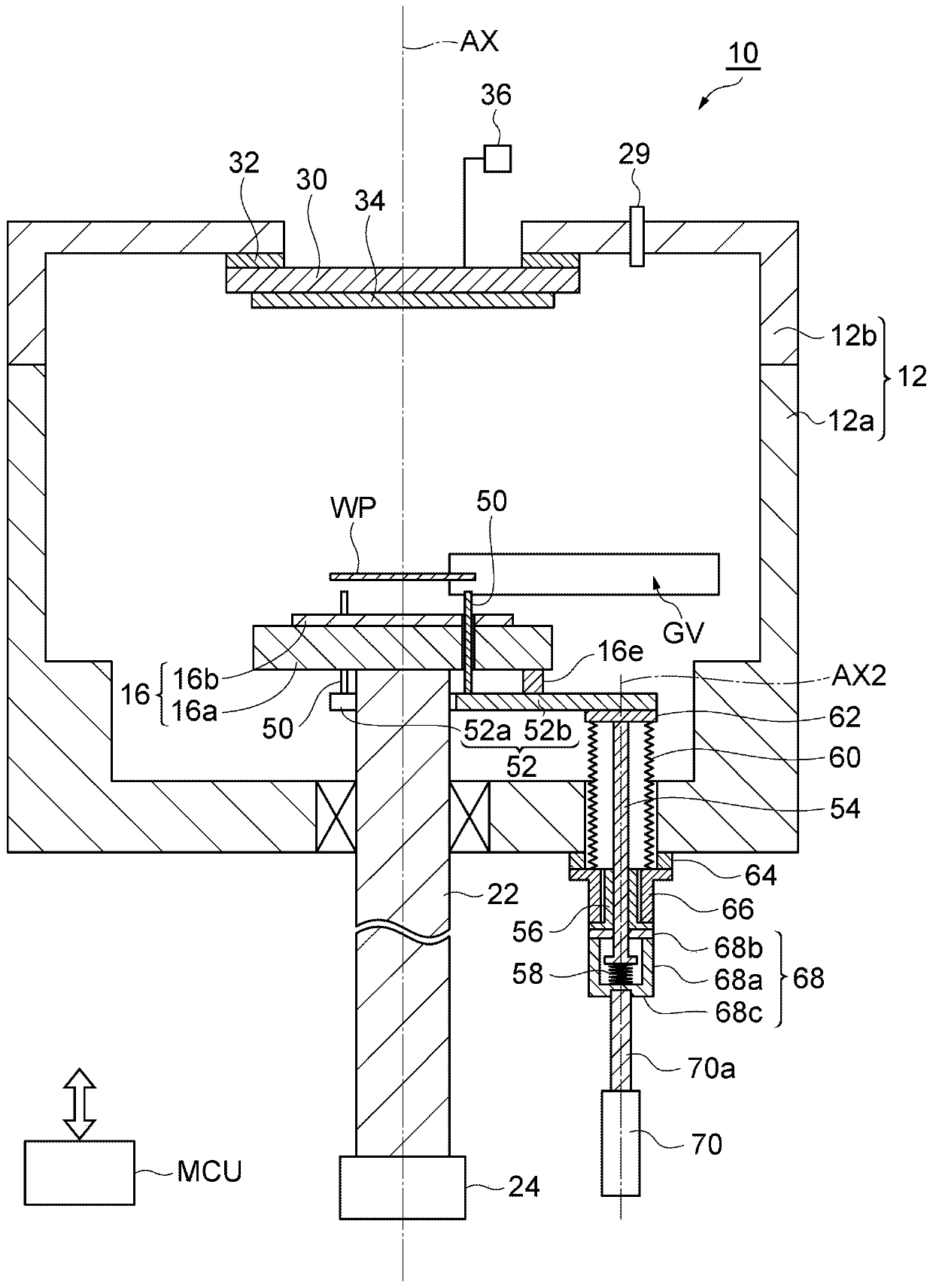

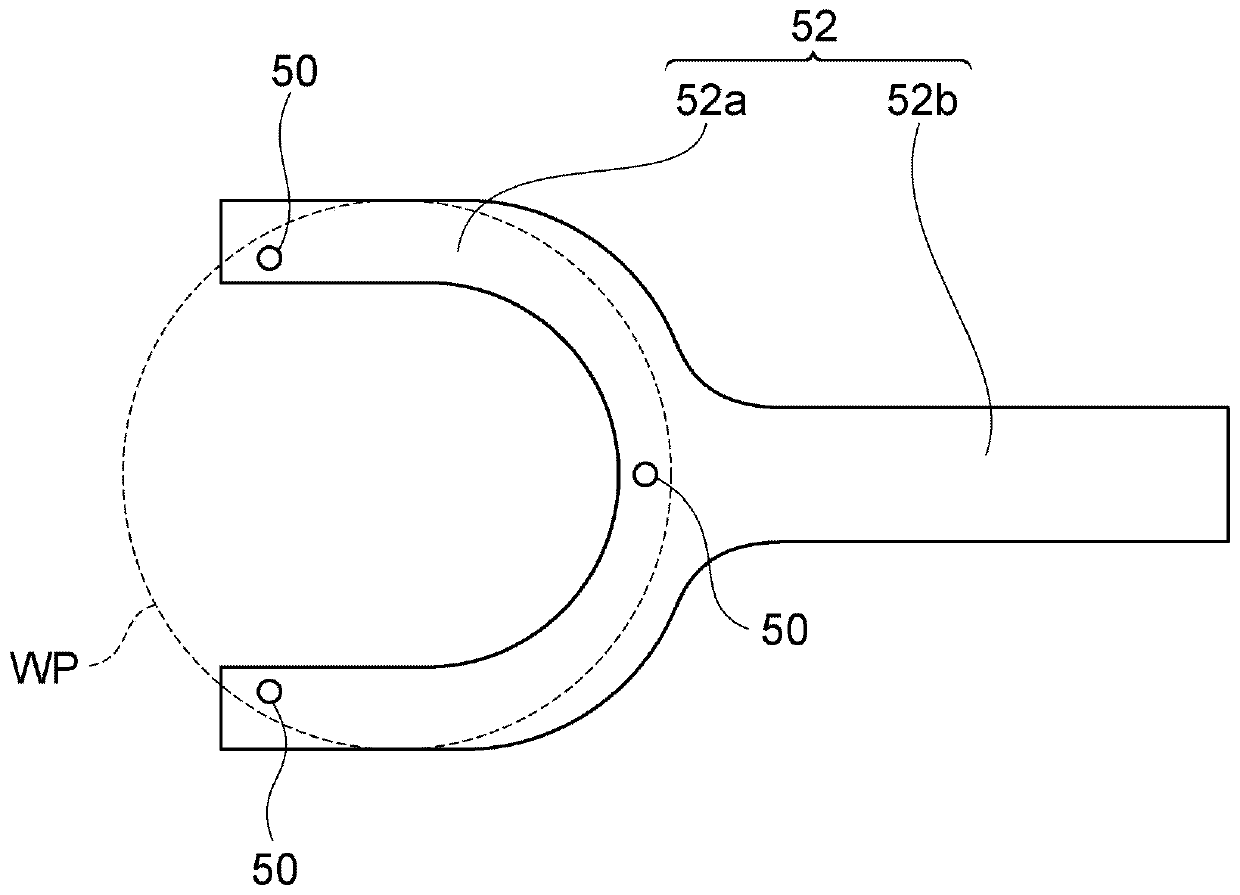

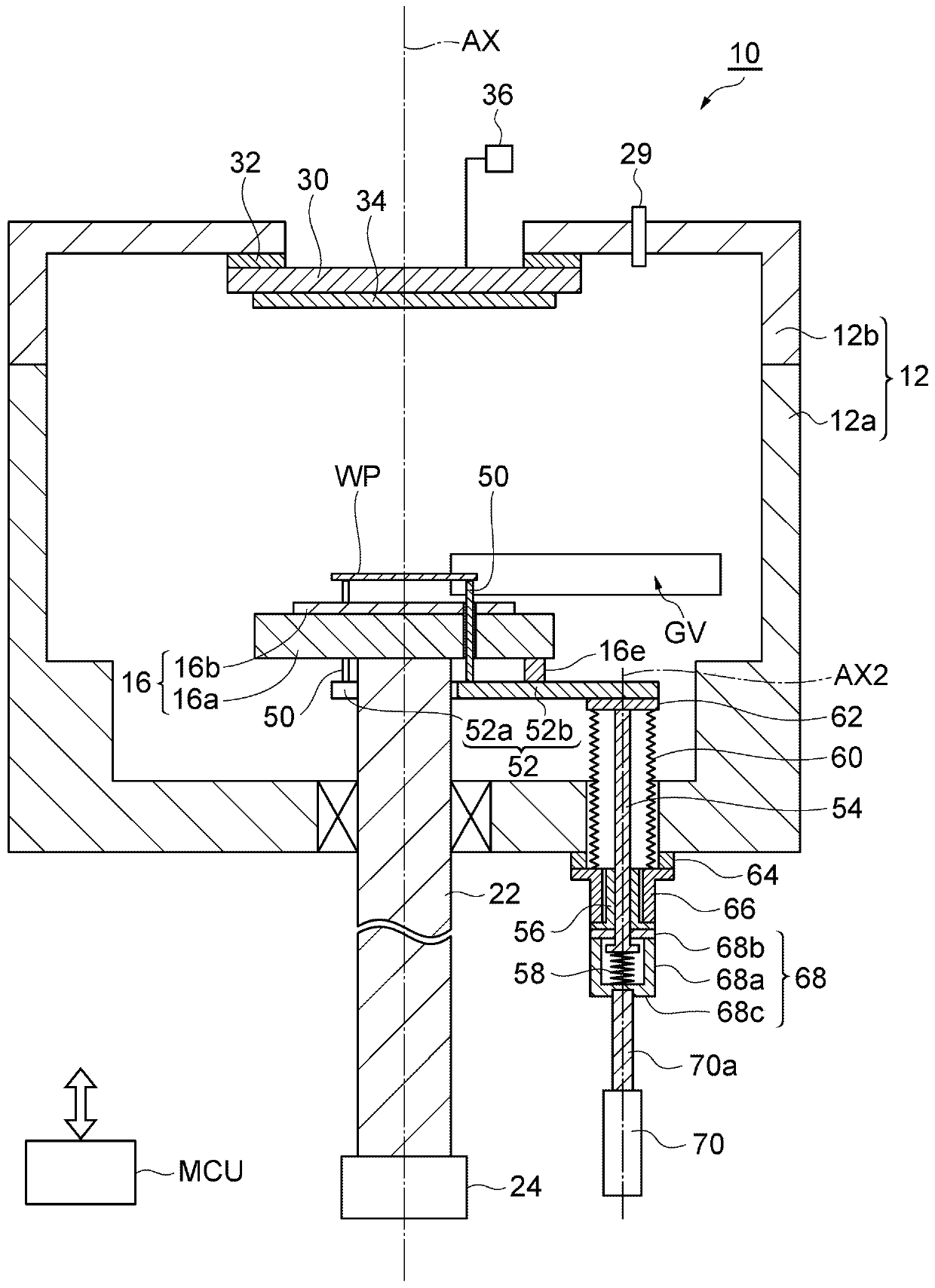

[0051] figure 1 It is a figure which schematically shows the processing apparatus of one embodiment. figure 1 The shown processing device 10 is configured as a film formation device. The processing device 10 has a processing container 12 . The internal space of the processing container 12 is a depressurizable space, and the internal space of the processing container 12 can be depressurized by an exhaust device. The processing container 12 includes a main body 12a and a lid 12b. The main body part 12a is formed in substantially cylindrical shape, and is opened at the upper end. In one embodiment, the main body portion 12a is formed in a substantially cylindrical shape, and the central axis of the main body portion 12a coincides with the axis AX. An opening for carrying i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com