Automatic yarn discharging device of warping machine

A warping machine, automatic technology, applied in the direction of warping machine, other manufacturing equipment/tools, textiles and papermaking, etc., can solve the problems of unsuitability for mass production, general work efficiency, inconvenient operation, etc., and achieve good promotion value , saving time and energy, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

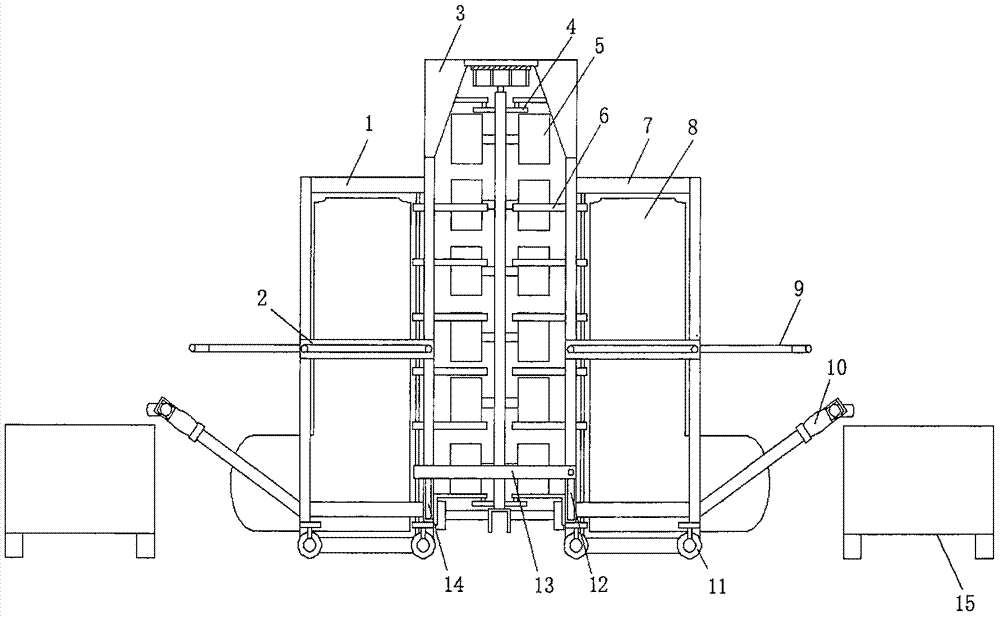

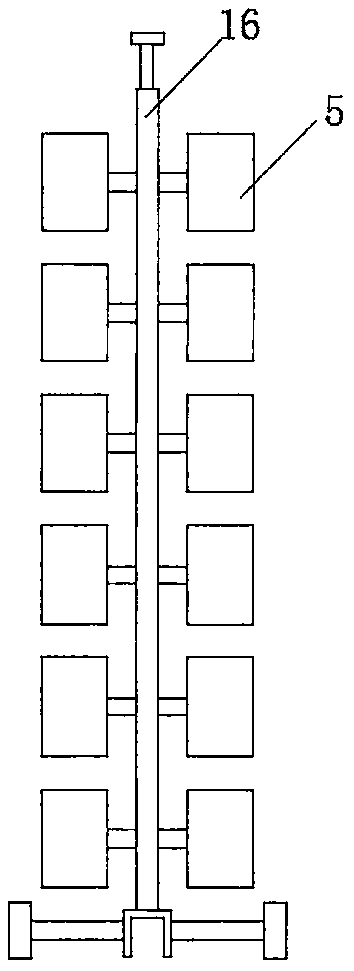

[0014] refer to Figure 1-2 , an automatic yarn lowering device for a warping machine, comprising a symmetrically arranged first frame body 1 and a second frame body 7, the first frame body 1 and the second frame body 7 are made of 304 stainless steel, have high hardness and are easy to clean, Durable and long in service life, the lower ends of the first frame body 1 and the second frame body 7 are symmetrically provided with four rolling wheels 11, and anti-skid lines are provided on the rolling wheels 11 to ensure the stability of the overall structure when moving. Body 1 and the opposite side of the second frame body 7 are provided with push handrails 9, both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com