An integrally formed integrated nozzle and its manufacturing method

A technology of integral molding and manufacturing methods, applied in the direction of jet propulsion devices, machines/engines, etc., can solve problems such as long molding time, many parts, and easy problems with structural reliability, so as to avoid assembly process, reduce force, Effect of reducing internal gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

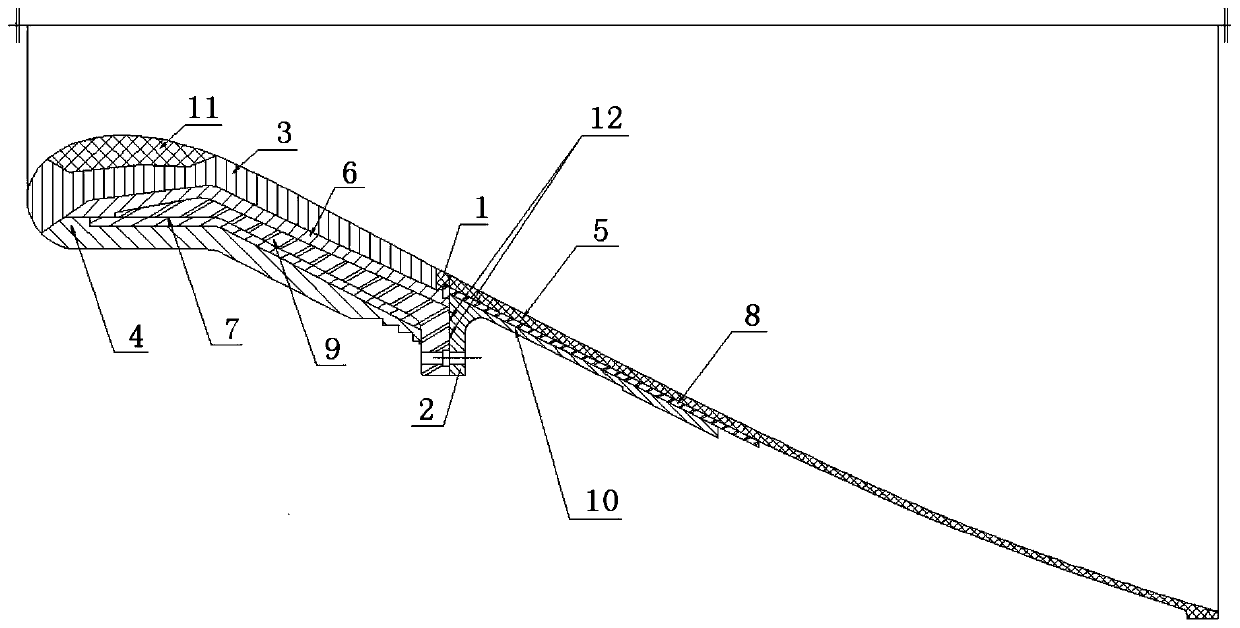

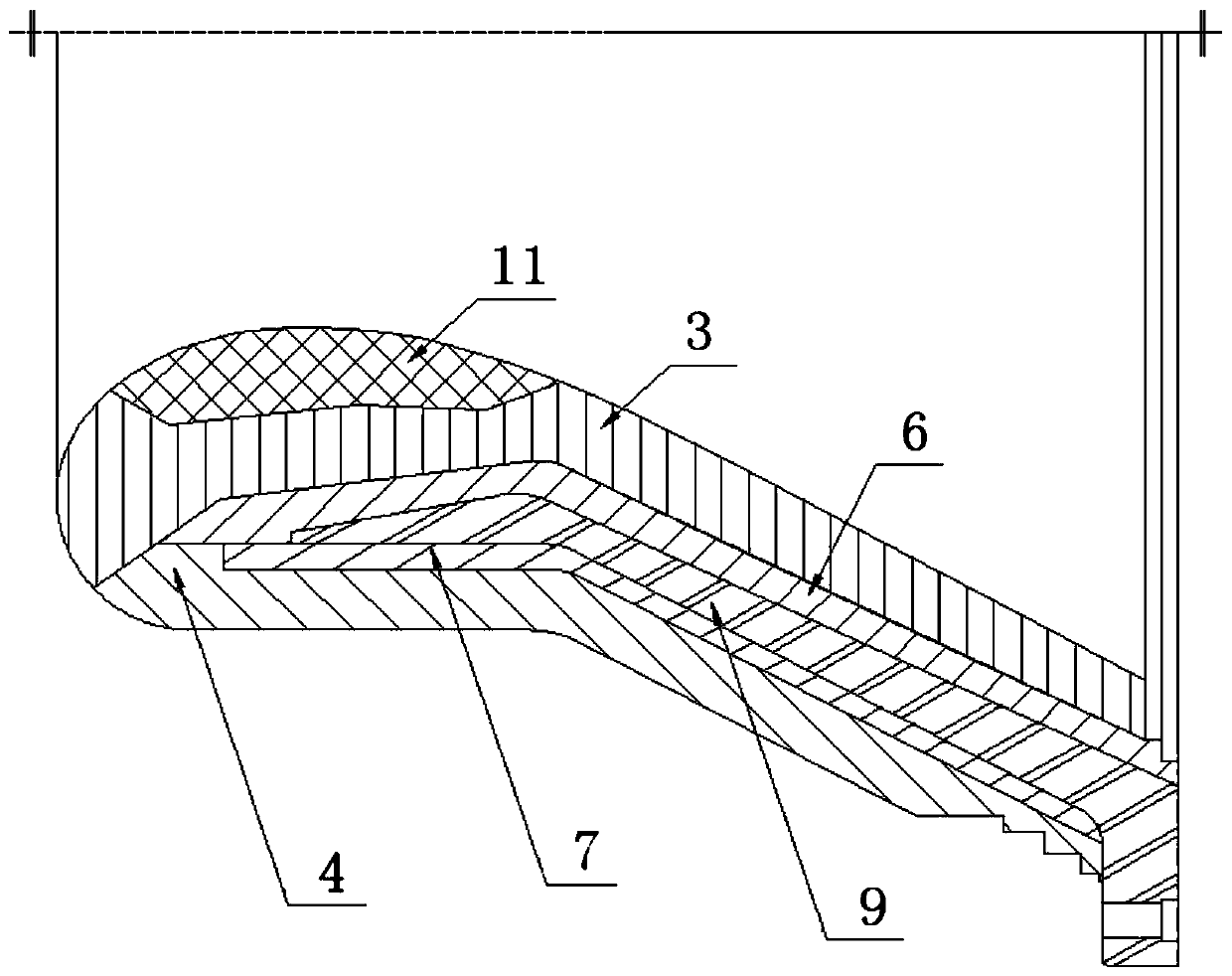

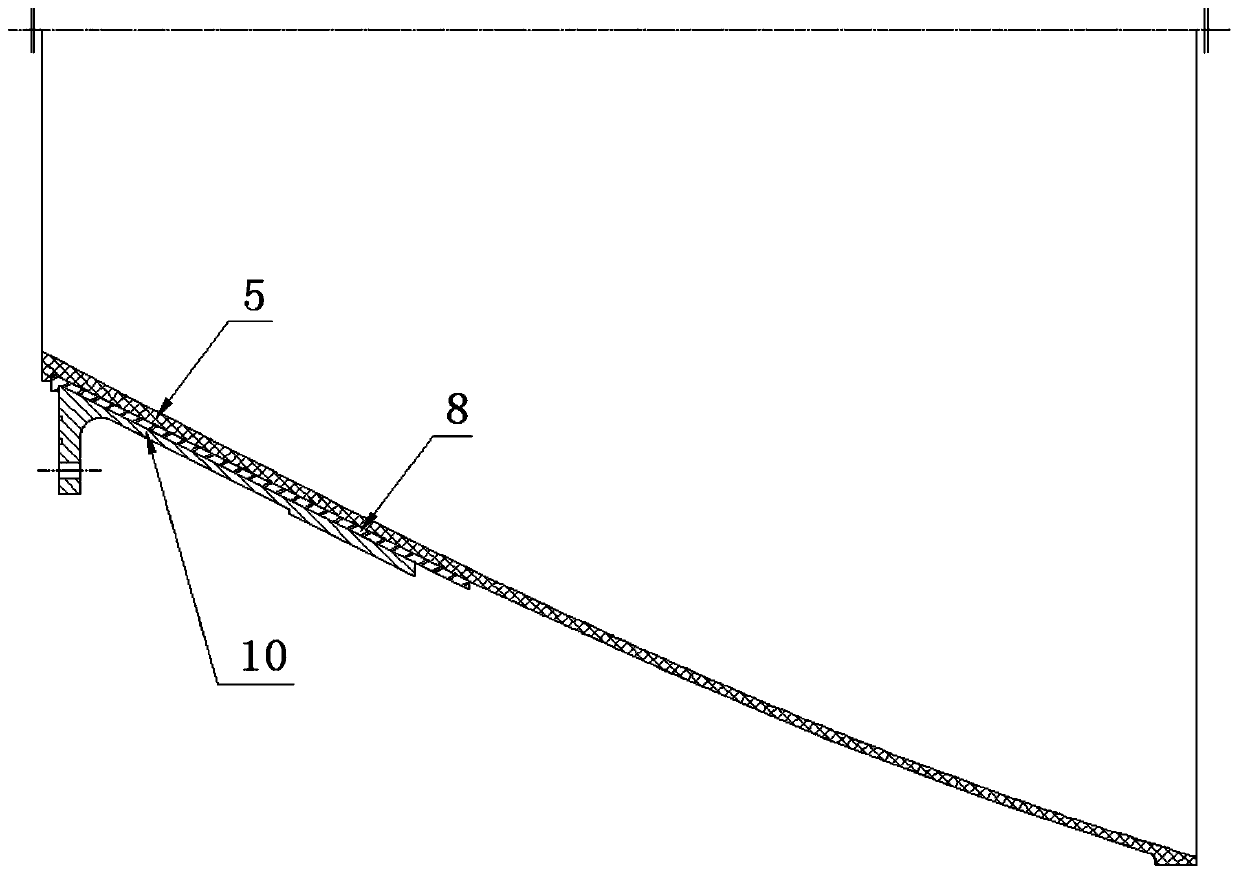

[0033] A kind of integrally formed integrated nozzle, such as figure 1 As shown, the throat liner, ablation-resistant layer, heat insulation layer, shell load-bearing layer and the plug fixed at the neck of the throat liner, the outer surface of the throat liner is used as the initial layer, the ablation-resistant layer, the insulation layer The thermal layer and the load-bearing layer of the casing are sequentially integrally formed into an integrated nozzle from the inside to the outside. In this embodiment, the throat liner, the ablation-resistant layer, the heat-insulating layer, and the load-bearing layer of the shell constitute two parts of the nozzle front section and the nozzle rear section of the integrated nozzle, and the ablation-resistant layer It includes an inner ablation layer, an outer ablation layer, and an expansion section, the heat insulation layer includes an inner heat insulation layer, an outer heat insulation layer, and an expanded heat insulation layer...

Embodiment 2

[0036] A method of manufacturing an integrally formed integrated nozzle corresponding to the first embodiment includes the following steps performed in sequence:

[0037] Step 1, the production of the front section of the nozzle, the sequence includes the following steps,

[0038] Step 11, mold installation, the throat liner is installed on the mold, and the outer surface of the mold matches and fits the inner surface of the nozzle;

[0039]Step 12. Wrap the inner ablation-resistant layer. The material is carbon cloth / phenolic. Wrap the carbon cloth / phenolic inner ablation layer on the outer wall of the throat liner. Since it is in a special shape, it can be carried out by laying + winding. The selection range of tape tension is 100N / mm-400N / mm, in this embodiment it is 200N / mm, the curing temperature is 80°C-200°C, in this embodiment it is 120°C, and the curing pressure is not lower than 2MPa. The medium is 2.5MPa, and the time is 1h~72h, which is 36h in this embodiment;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com