A kind of black tea production method

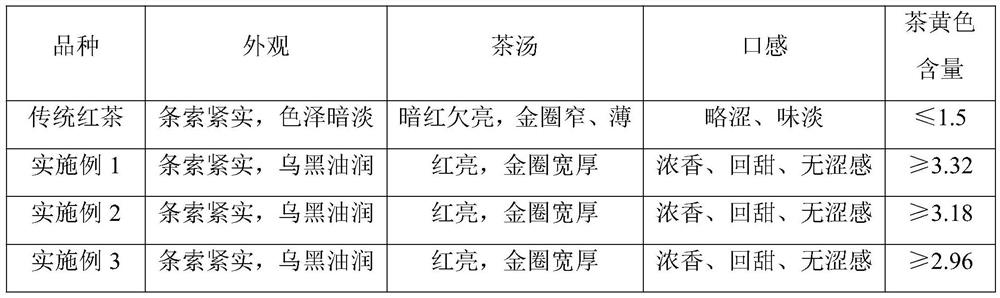

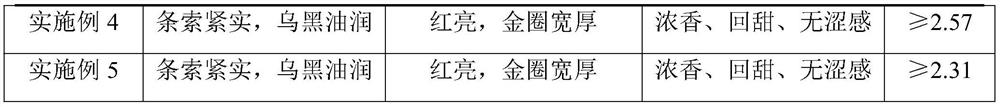

A production method and technology for black tea, applied in the field of tea processing, can solve the problems of high dependence on experience and technology, uneven quality of black tea, etc., and achieve the effects of red and bright tea soup, sweet taste, and good constant temperature control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

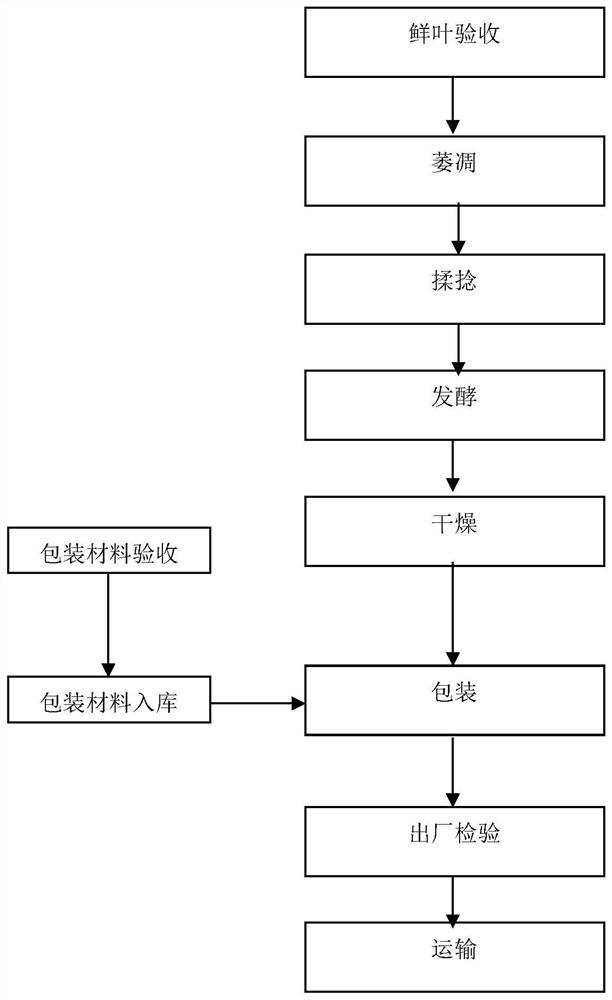

[0031] like figure 1 As shown, a method for producing black tea, the steps include:

[0032] S1. Fresh leaf acceptance: collect fresh tea leaves, check and wash;

[0033] S2. Withering: the tea leaves are withered by evaporating the inner water content of the tea leaves, the withering temperature is controlled at 35°C, the time is controlled at 3 hours, and the water content of the tea leaves after withering is controlled at 62%;

[0034] S3. Kneading: the tea leaves are kneaded, and the kneading time is controlled at 80 minutes;

[0035] S4. Fermentation: put the tea leaves in the fermentation room for fermentation, keep the fermentation room cool and ventilated, and control the absolute humidity of the fermentation room at 20g / m2 3 , the relative humidity is controlled at 98%, the fermentation temperature is constant at 25 ℃, the fermentation chamber is equipped with a central controller, a temperature detector and a water mist injector, and the temperature detector and th...

Embodiment 2

[0041] like figure 1 As shown, a method for producing black tea, the steps include:

[0042] S1. Fresh leaf acceptance: collect fresh tea leaves, check and wash;

[0043] S2. Withering: the tea leaves are withered by evaporating the inner water content of the tea leaves, the withering temperature is controlled at 30°C, the time is controlled at 3 hours, and the water content of the tea leaves after withering is controlled at 58%;

[0044] S3. Kneading: the tea leaves are kneaded, and the kneading time is controlled at 70 minutes;

[0045] S4. Fermentation: put the tea leaves in the fermentation room for fermentation, keep the fermentation room cool and ventilated, and control the absolute humidity of the fermentation room at 5g / m2 3 , the relative humidity is controlled at 95%, the fermentation temperature is constant at 25 ℃, the fermentation chamber is equipped with a central controller, a temperature detector and a water mist injector, and the temperature detector and the...

Embodiment 3

[0051] like figure 1 As shown, a method for producing black tea, the steps include:

[0052] S1. Fresh leaf acceptance: collect fresh tea leaves, check and wash;

[0053] S2. Withering: the tea leaves are withered by evaporating the inner water content of the tea leaves, the withering temperature is controlled at 40°C, the time is controlled at 4 hours, and the water content of the tea leaves after withering is controlled at 64%;

[0054] S3. Kneading: the tea leaves are kneaded, and the kneading time is controlled at 90 minutes;

[0055] S4. Fermentation: put the tea leaves in the fermentation room for fermentation, keep the fermentation room cool and ventilated, and control the absolute humidity of the fermentation room at 28g / m2 3 , the relative humidity is controlled at 100%, the fermentation temperature is constant at 25 ℃, the fermentation chamber is equipped with a central controller, a temperature detector and a water mist injector, and the temperature detector and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com