a cup lid

A cup lid and flip lid technology, applied in the field of cup lids, can solve problems such as hidden dangers, scalds, hot water leakage, etc., and achieve the effects of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

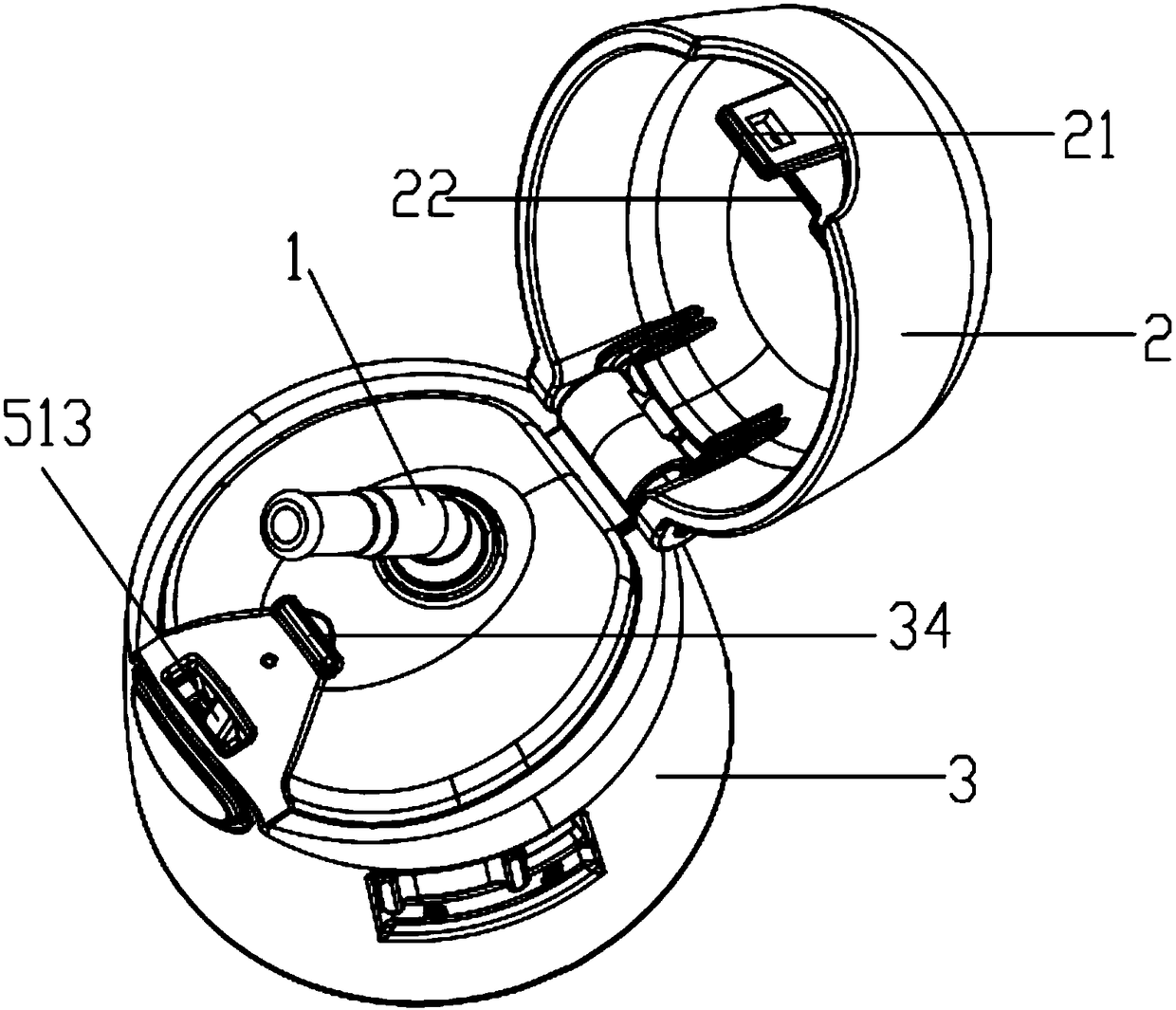

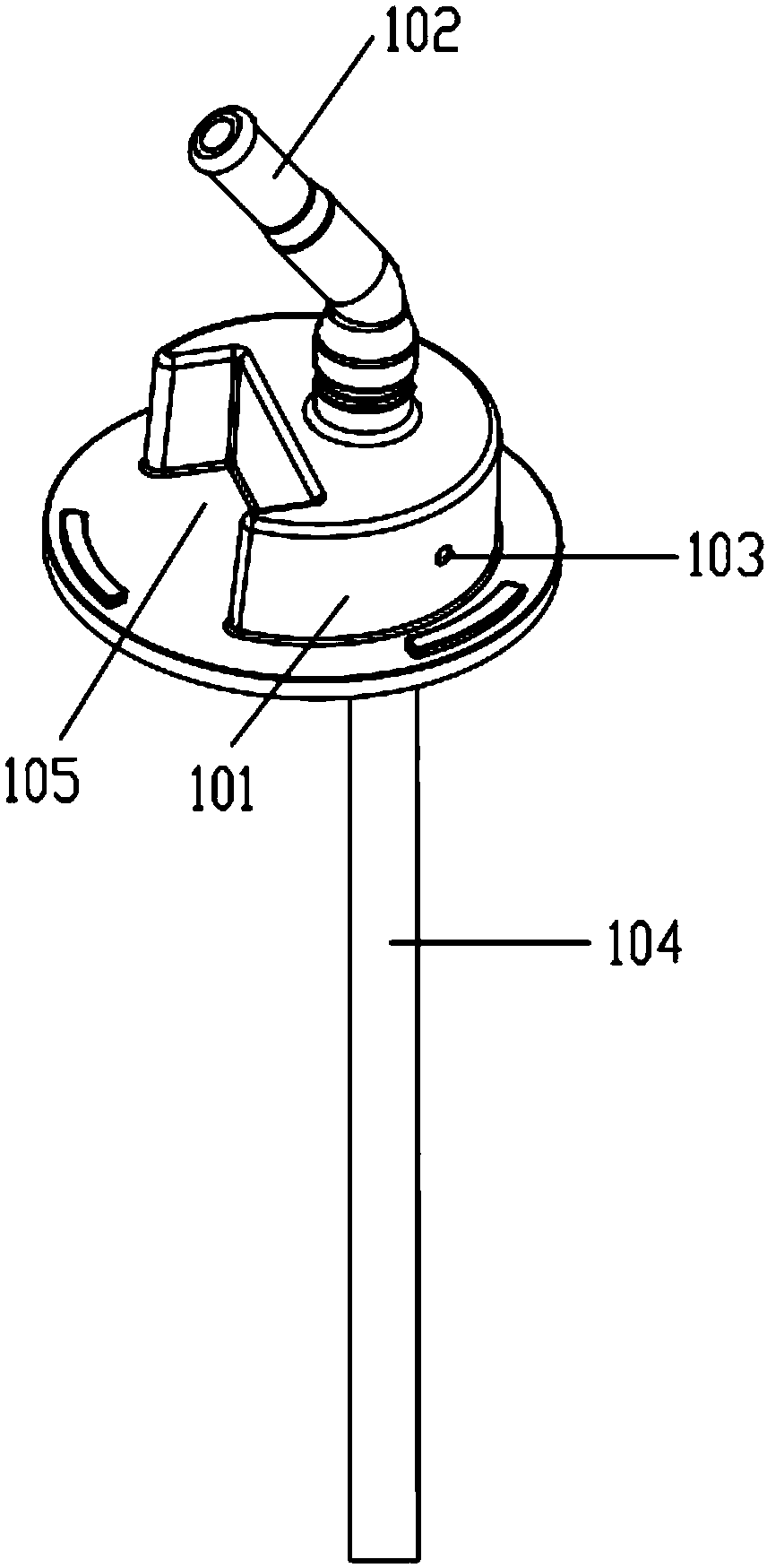

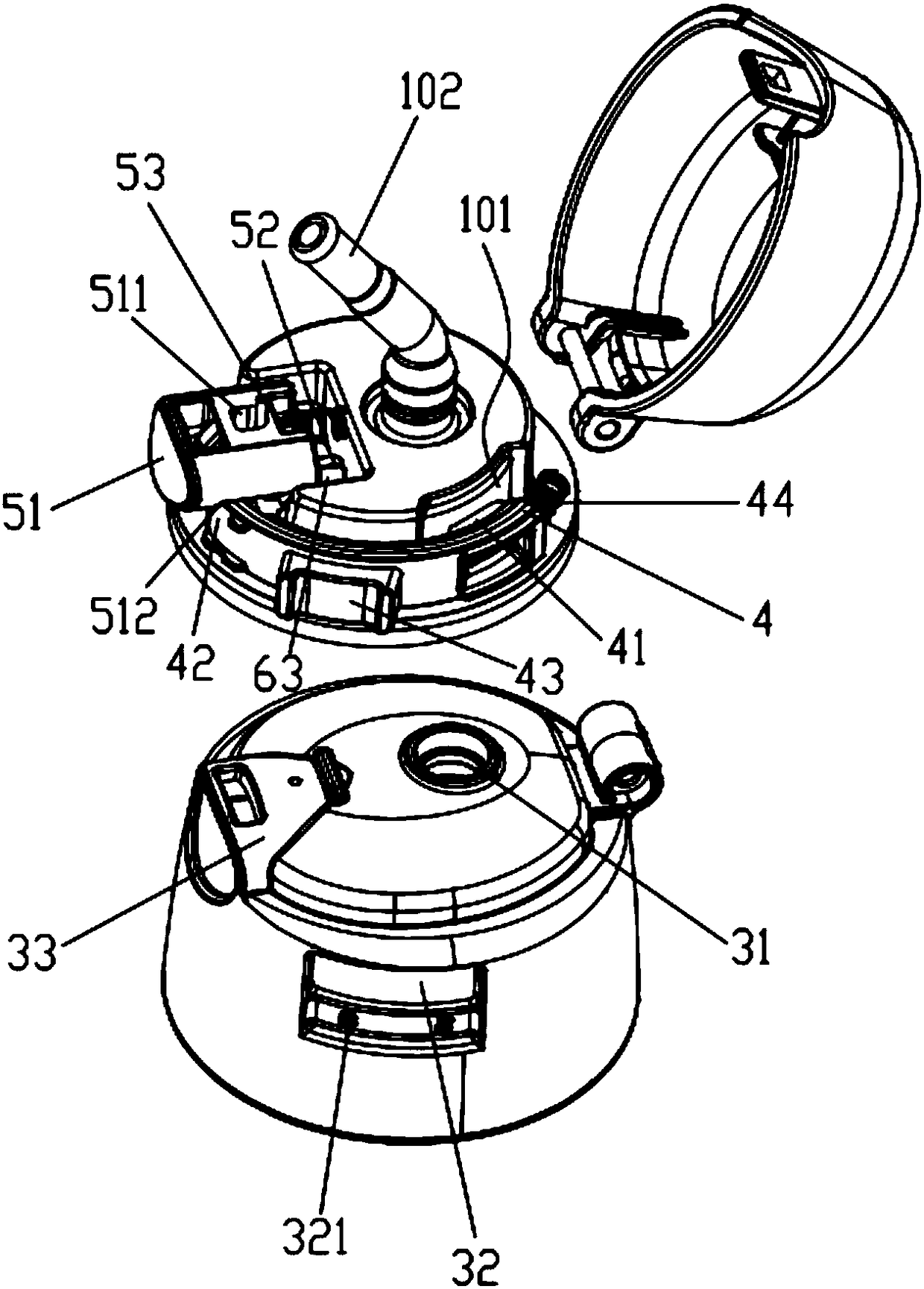

[0020] Embodiment one, with reference to Figure 1 to Figure 5 , a kind of cup cover provided by the present invention includes a cup cover body and a suction nozzle 1, the cup cover body includes an upper cover 2 and a lower cover 3, the upper cover 2 and the lower cover 3 can be flipped and hinged, and the suction nozzle 1 includes a suction nozzle Seat 101 and the suction part 102 and suction pipe 104 installed on the nozzle seat 101, the suction pipe 104 communicates with the suction part 102, the suction nozzle seat 101 is installed on the lower end surface of the lower cover 3, and the suction part 102 passes through the through hole provided on the lower cover 3 31 extends above the lower cover 3, the nozzle seat 101 is provided with a vent hole 103, the lower cover 3 is also provided with a slider 4 that can move back and forth relative to the lower cover 3, and the slider 4 is provided with a valve for closing the vent hole 103. The sealing block 41 and the sliding bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com