Smoothing head mechanism for squeezing flat plate mop

A flat mop with two-end technology, which is applied to cleaning floors, cleaning machines, and carpets, etc. It can solve the problems of wiper wear, high friction, and inability to squeeze water when rubbing the mouth, and achieves free control of the size of the opening and low friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

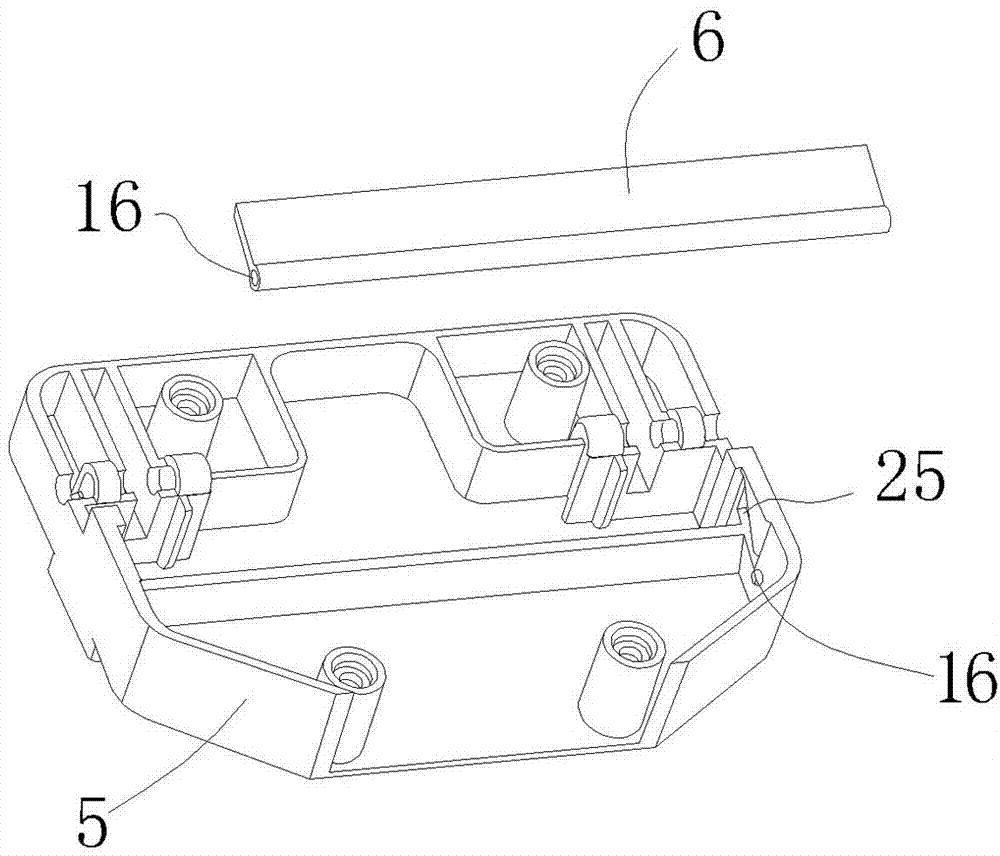

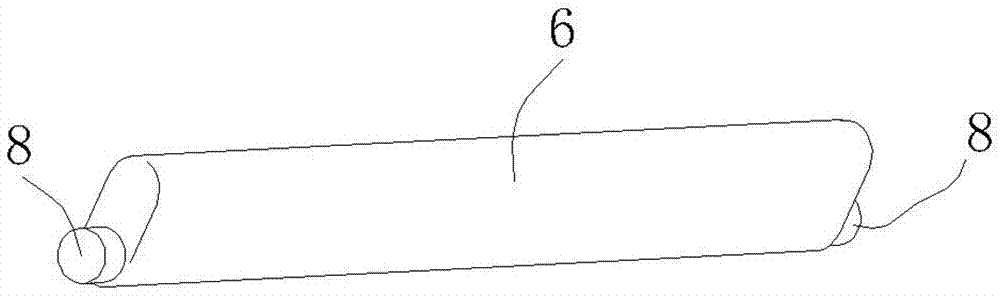

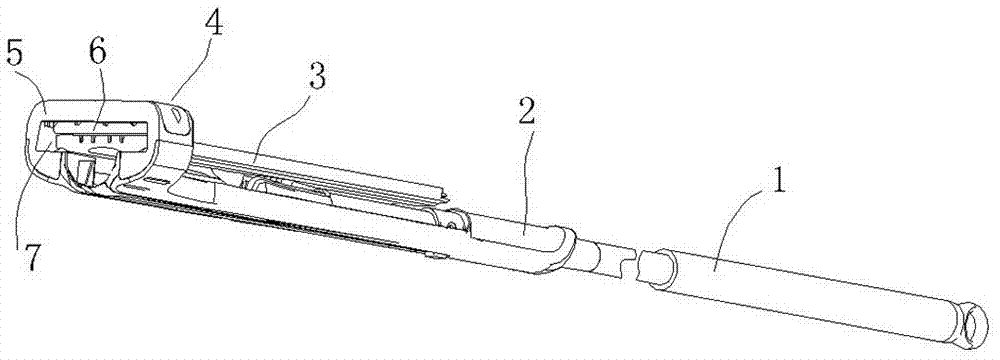

[0048] refer to Figure 1-Figure 4, a kind of single-sided squeezing horizontal board mop, comprising mop rod 1, mop rod 1 is provided with squeezing handle 2, the lower end of mop rod 1 is movably connected with flat mop board 3, and one side of flat mop board 3 is provided with wiper. The lower end of the squeeze handle 2 is provided with a stroke head mechanism 4, and the stroke head mechanism 4 includes a squeeze frame 5, and an opening is provided on the squeeze frame 5, and a stroke plate 6 is arranged in the opening, so that A stroker 7 is formed between the plate 6 and the opening, and the stroker 6 is rotatably connected in the opening, and the stroker 6 can change the width of the stroker 7 during the rotation, so as to adjust the width of the stroker 7 The opening width can be adjusted.

[0049] refer to figure 1 , Figure 13 , Figure 14 , Figure 21 , Figure 22 , in this embodiment, the two ends of the stroker 6 are rotatably connected in the opening: both ...

Embodiment 2

[0059] refer to figure 1 , Figure 5~Figure 7 , a kind of double-sided squeeze horizontal board mop, comprising mop rod 1, mop rod 1 is provided with squeezing handle 2, the lower end of mop rod 1 is movably connected with flat mop board 3, and both sides of flat mop board 3 are provided with wiping objects . The lower end of the squeeze handle 2 is provided with a head-stroke mechanism 4, the head-stroke mechanism 4 includes a squeeze frame 5, and an opening is provided on the squeeze frame 5, and two stroke plates 6 are arranged in the opening, so that A stroke mouth 7 is formed between the two stroke boards 6, and the stroke board 6 is rotatably connected in the opening, and the stroke board 6 can change the width of the stroke mouth 7 during the rotation, so that the stroke mouth 7 The size of the opening width can be adjusted

[0060] refer to figure 1 , Figure 13 , Figure 14 , Figure 21 , Figure 22 , in this embodiment, the two ends of the stroker 6 are rotat...

Embodiment 3

[0070] refer to figure 1 , Figure 8~Figure 12 , an extruded flat-panel cleaning tool with a bucket, comprising a mop bucket 10 and a mop, the mop comprising a mop rod 1, the lower end of the mop rod 1 is movably connected with a flat mop board 3, and one side of the flat mop board 3 is provided with a wiping things. The mop bucket 10 is provided with a head-stroke mechanism, and the head-stroke mechanism includes a squeeze frame 5, and an opening is provided on the squeeze frame 5, and a stroke plate 6 is provided in the opening, so that the stroke plate 6 and the A stroker mouth 7 is formed between the openings, and the stroker plate 6 is rotatably connected in the opening, and the stroker plate 6 can change the width of the stroker mouth 7 during the rotation, thereby adjusting the opening width of the stroker mouth 7 Make adjustments. Certainly also can all be provided with wiping thing on the both sides of flat mop plate, establish and set two stroker boards simultaneo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com