Installation device of sliding plug door system of multiple-unit train

A system installation and EMU technology, applied in the field of EMU plug door system installation device, can solve the problems of low installation accuracy and installation efficiency, and achieve the effects of improved installation accuracy and installation efficiency, and enhanced practicability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

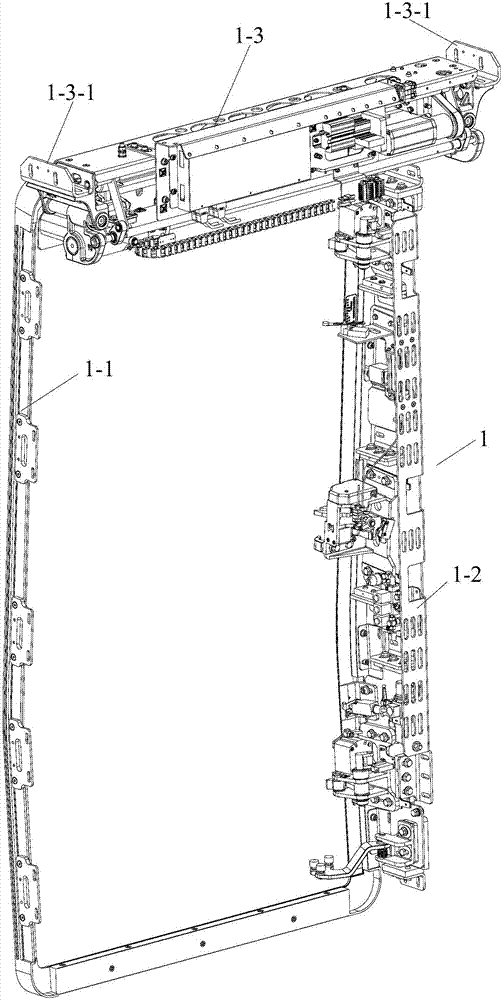

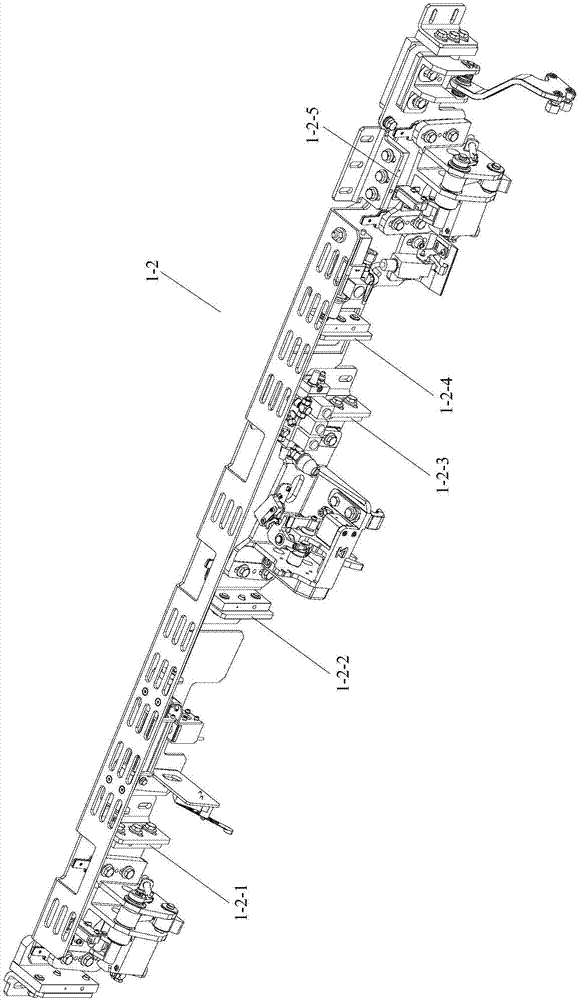

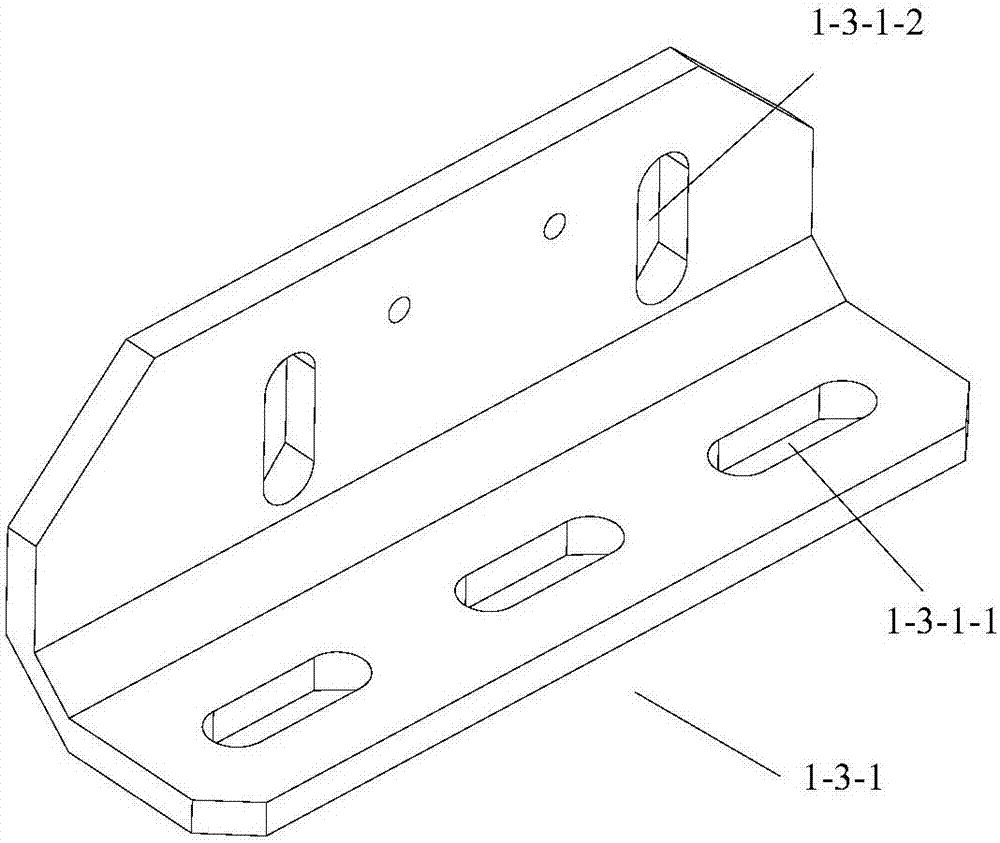

[0038] like Figure 4 to Figure 17 As shown, the EMU plug door system installation device of the present invention includes: a movable door frame clamping mechanism 2, a driving mechanism height positioning mechanism 3, a vehicle body upper positioning mechanism 4, a vehicle body lower positioning mechanism 5 and an equipment rack mounting mechanism 6.

[0039] The movable door frame clamping mechanism 2 includes a rectangular frame 2-1, a door frame conformal support structure 2-2, a plurality of clamps 2-3 on both sides of the door frame, two upper columns 2-4, two lower columns 2-5, Two side clamps 2-6, two upper body clamps 2-7, two lower body clamps 2-8, two door frame upper quick clamps 2-9, two door frame uppers Support 2-10, two door frame lower quick clamps 2-11, two door frame lower supports 2-12, two upper quick clamps 2-13, two upper positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com