A visual measurement method for shield tail gap of shield machine

A shield tail gap and visual measurement technology, applied in the field of image processing, can solve the problems of inaccurate measurement results, complex measurement methods, and many hardware devices, and achieve high detection accuracy, improve accuracy, and reduce hardware loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

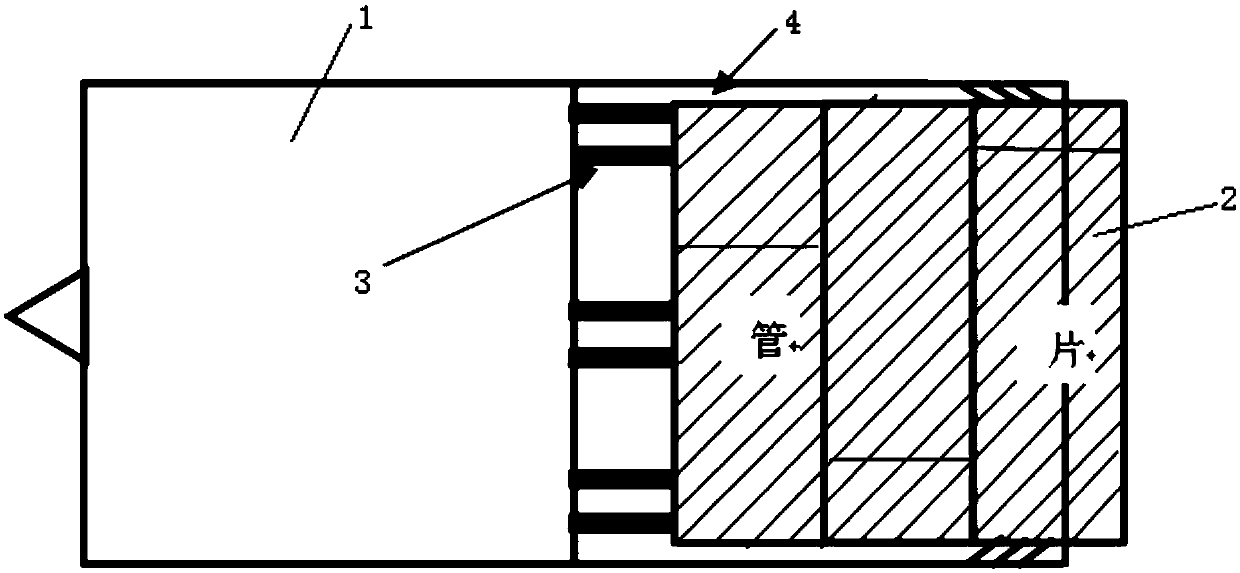

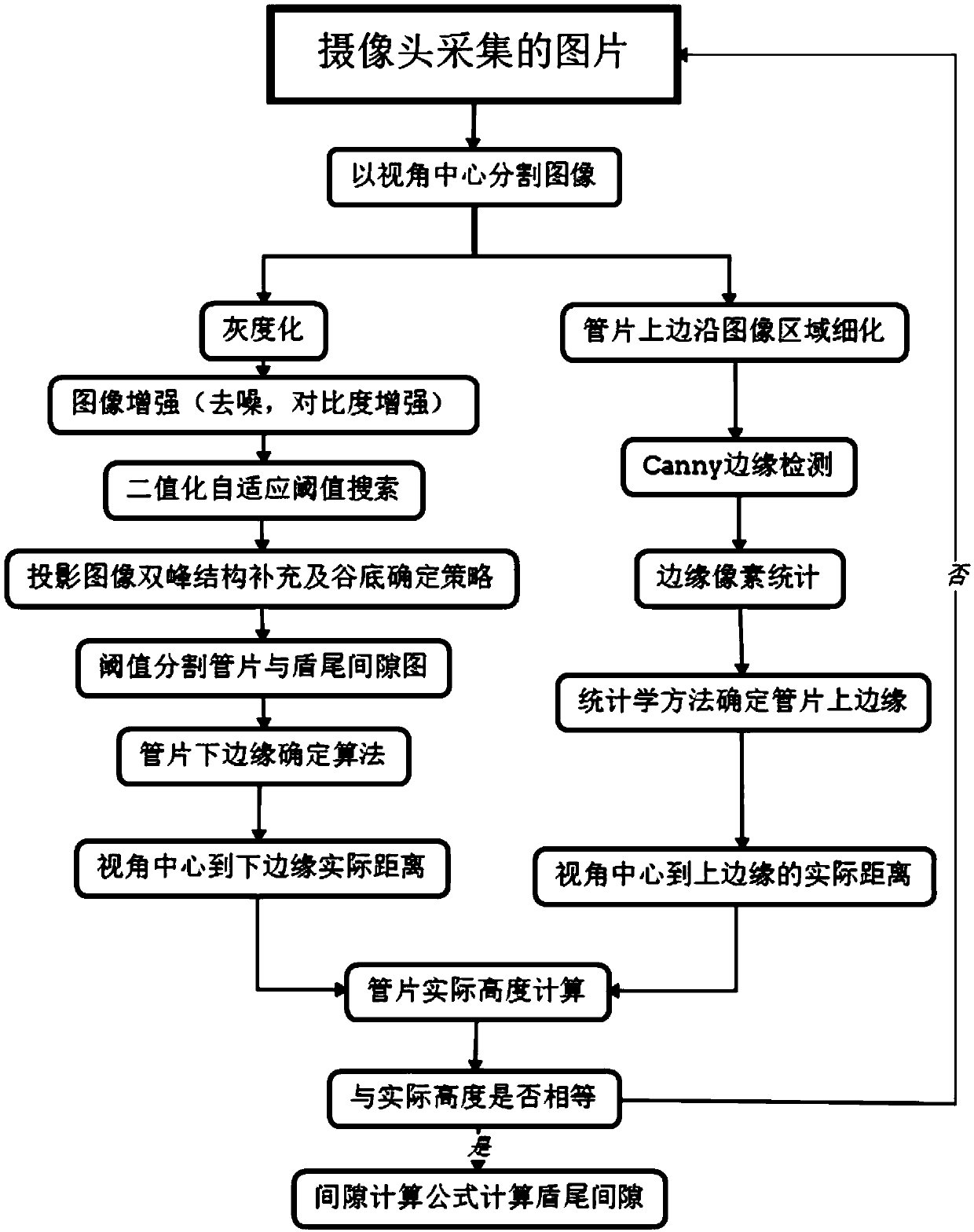

[0042] Such as figure 2 As shown, a shield tail gap visual measurement method of shield machine, the method includes the following steps:

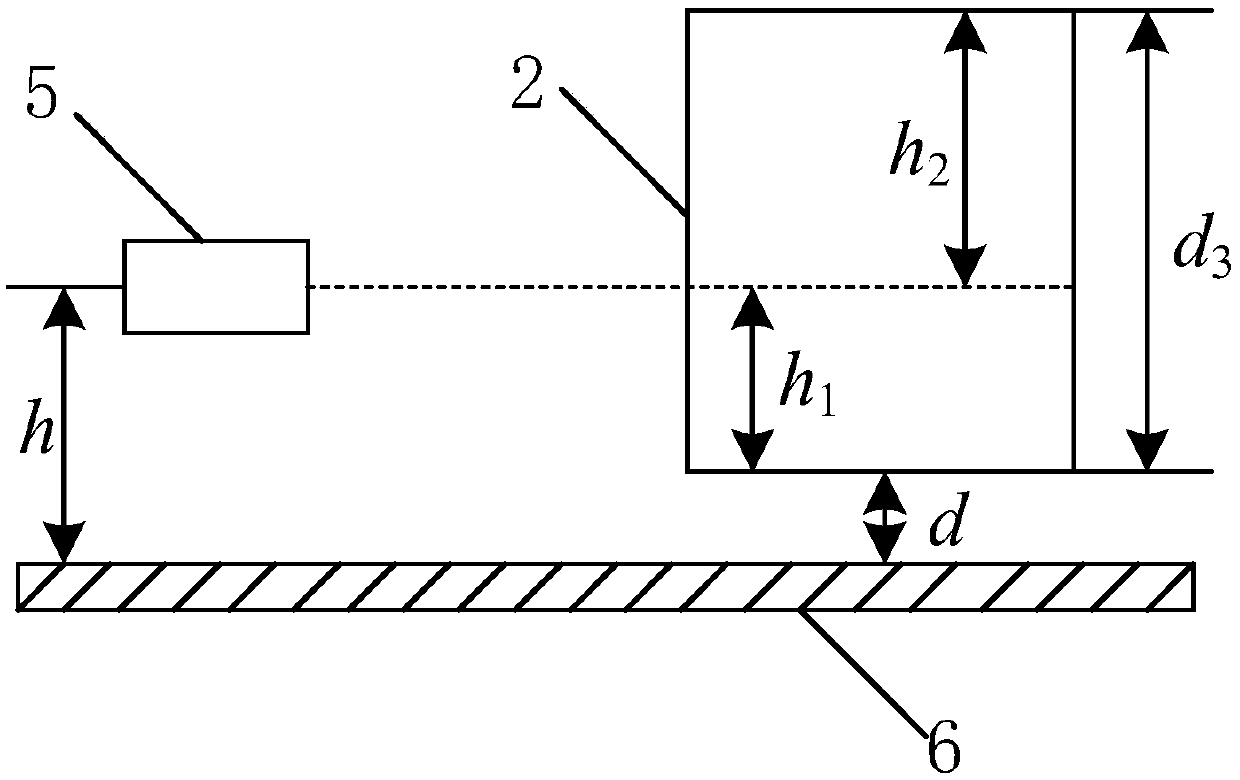

[0043] (1) install the camera 5, the height of the camera from the shield shell 6 at the bottom of the shield machine is h;

[0044] (2) Camera 5 captures the original image during the working process of the shield machine, which includes the upper edge of the segment and the lower edge of the segment, and the lower edge of the segment is the upper edge of the shield tail gap;

[0045] (3) The original image is divided into a first sub-image and a second sub-image by taking the horizontal axis where the center point of the original image is located as a dividing line, wherein the first sub-image includes the lower edge of the segment, and the second sub-image includes the upper edge of the segment ;

[0046] (4) Obtain the upper edge of the segment from the second sub-image, and calculate the distance d between the upper edge of the seg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com