Frame for display equipment and manufacturing method of frame

A display device and frame technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of affecting the appearance of the display, cumbersome manufacturing process, easy to fall into dust, etc., to improve the appearance quality, low cost, easy to process and shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

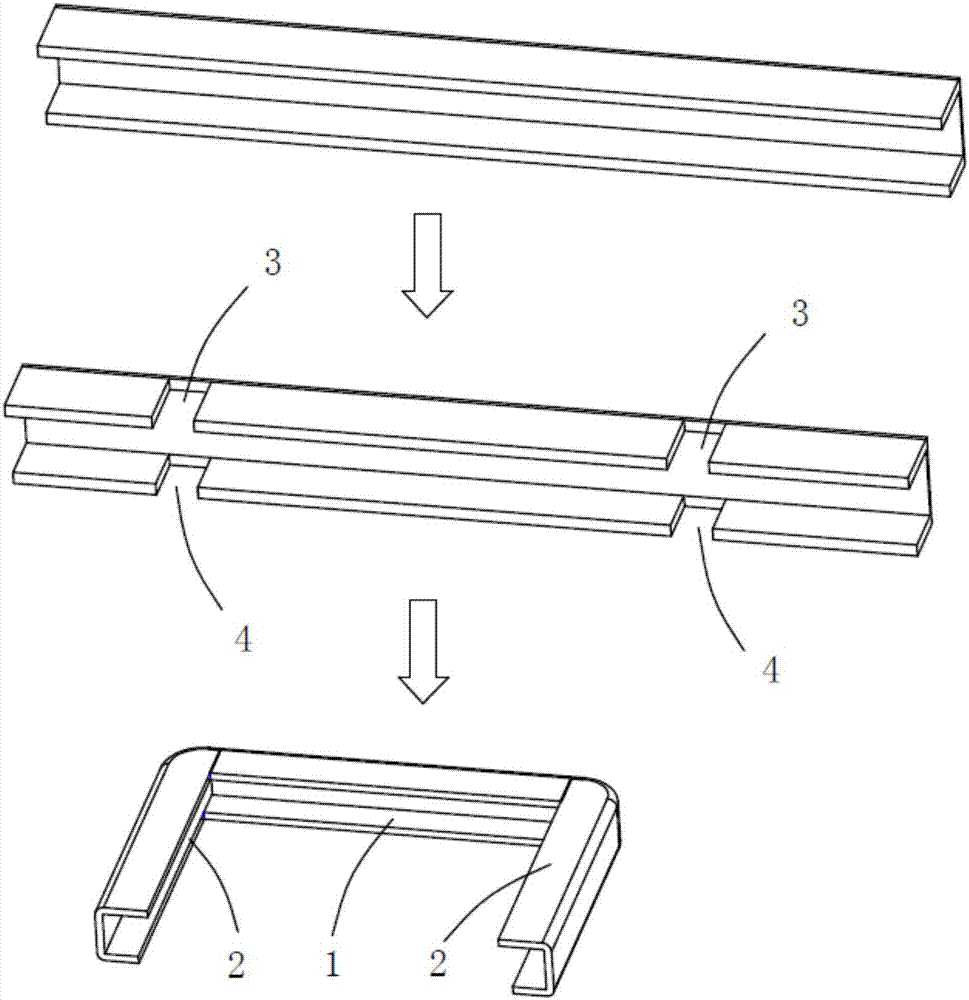

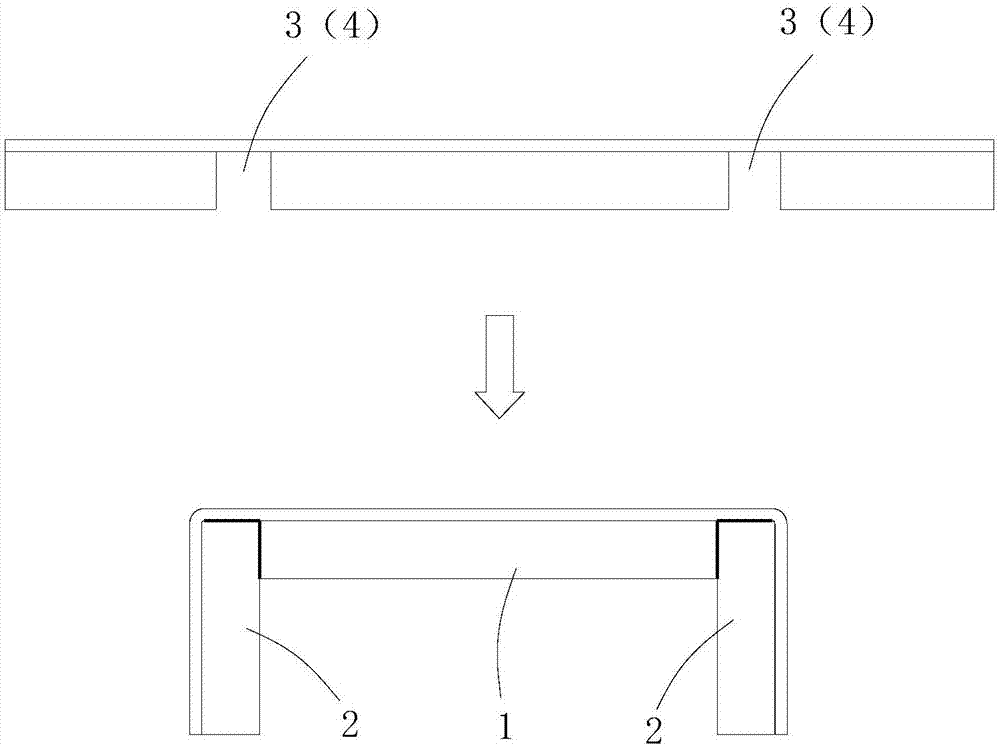

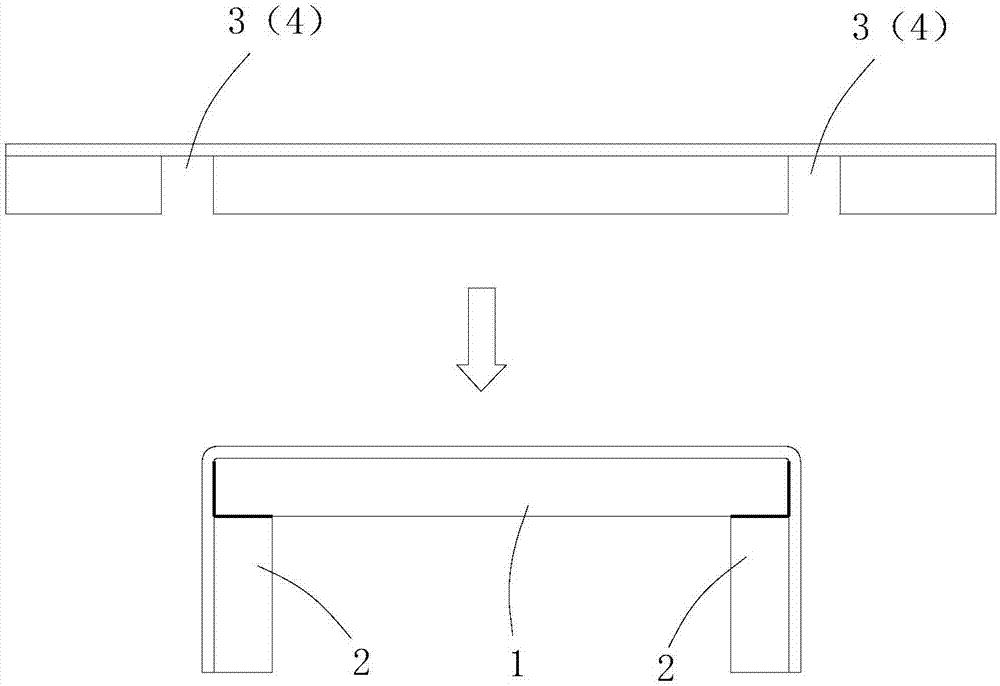

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] Such as Figures 1 to 7 As shown, a frame for a display device includes: a frame body with a U-shaped cross-section, and the two ends of the frame body are respectively bent 90° toward the opening direction to form a top frame 1 and two side frames 2; The inner side of the bend between the frame 1 and the side frame 2 is provided with a first notch 3 for the upper end of the top frame 1 and the upper end of the side frame 2 to be bent and butted, and for the lower end of the top frame 1 The first notch 3 and the second notch 4 are correspondingly arranged up and down along the height direction of the bending line of the bending position.

[0031] The invention provides a frame for a display device, which is integrally formed and has high structural strength, can effectively prevent dust from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com