Multistage variable-pressure oil cylinder and control method thereof

A control method and variable pressure oil technology, applied in the field of hydraulic cylinders, can solve problems such as the inability to meet the requirements of multi-stage pressure control, and achieve the effects of stable modulation and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

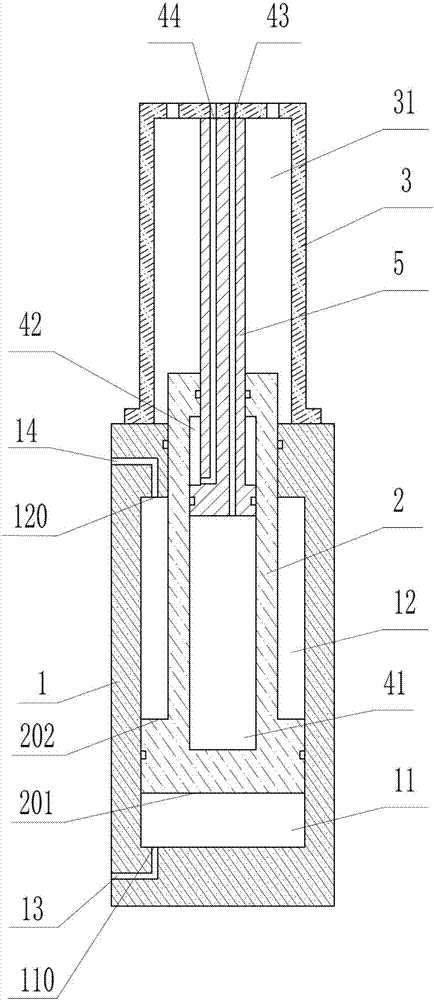

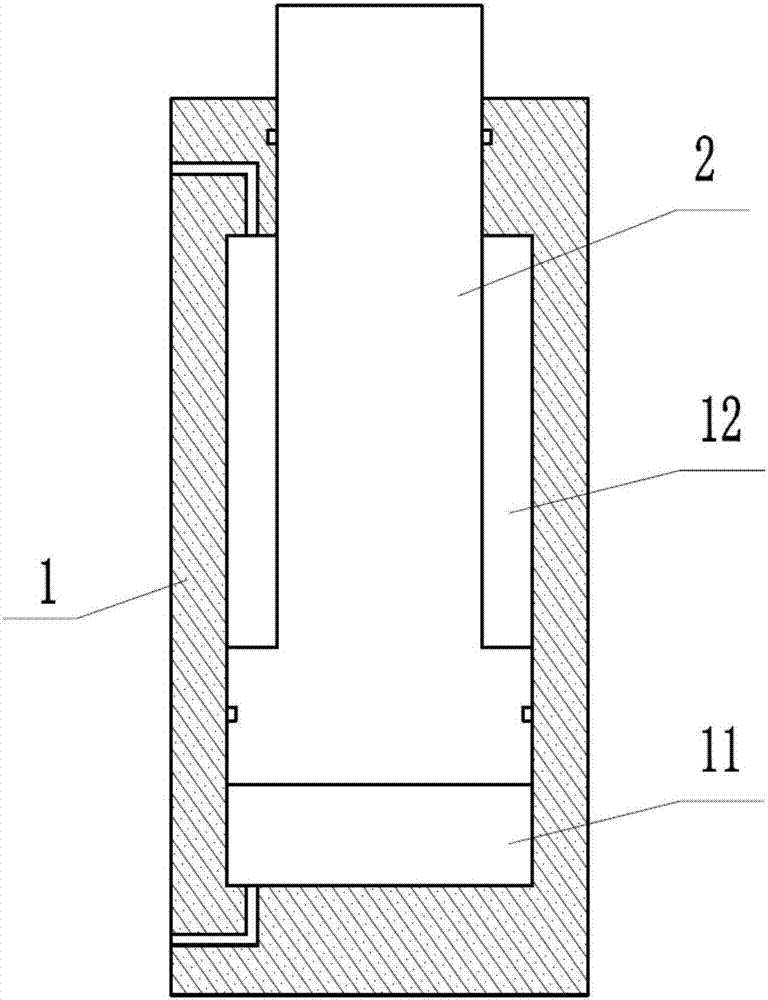

[0028] Such as figure 1 As shown, a multi-stage variable pressure oil cylinder includes a first-stage cylinder body 1, a first-stage piston rod 2 and a protective cover tube 3;

[0029] The first-stage cylinder 1 is installed with the first-stage piston rod 2 that can be pushed out or recovered, the protective cover tube 3 is arranged at one end of the first-stage cylinder 1, and the first-stage piston rod 2 The rod end protrudes from the primary cylinder 1 and is located in the protective cavity 31 of the protective cover tube 3. The inner oil chamber of the primary cylinder 1 is divided into the first oil chamber by the primary piston rod 2. A cavity 11 and a second oil cavity 12, the cross-sectional area of the first oil cavity 11 is larger than that of the second oil cavity 12;

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com