Novel carbodiimides, method for the production and use thereof

A carbodiimide, carbon atom technology, applied in the field of protection from hydrolysis degradation, can solve the problems of insufficient reactivity stabilization, no, no hydrolysis-inhibition effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Exemplary implementation

[0075] Test on:

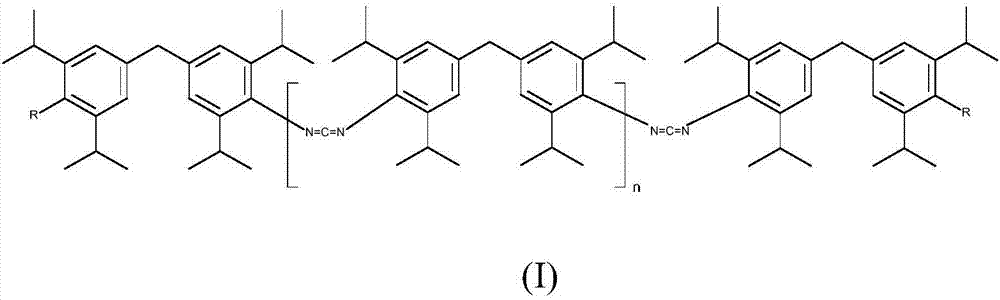

[0076] 1) CDI(A): Carbodiimides according to formula (I), wherein R=NCO and n>20, have an NCN content of about 11 wt % and have an NCO content of <1 wt %, comp.

[0077] 2) CDI(B): carbodiimides of formula (I), wherein R = -NHCOOR III and R III = Cyclohexyl with an NCN content of about 6 wt% and n = about 3, invented.

[0078] Comparative Carbodiimides Production of CDI(A)

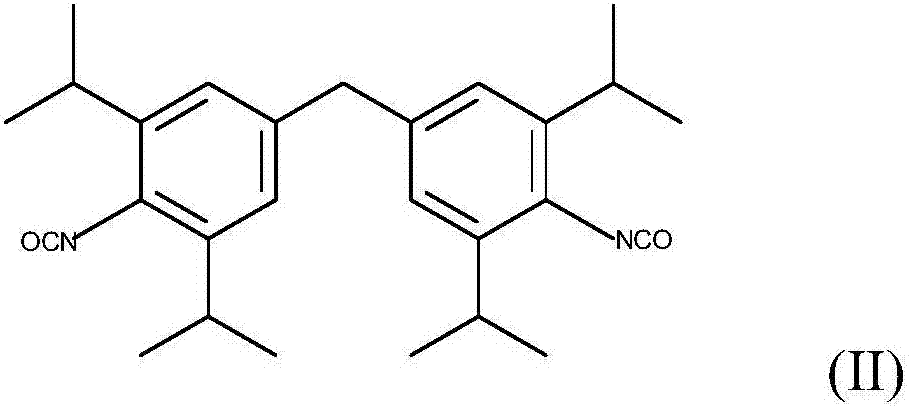

[0079] A 250 ml four-necked flask, which had been baked and purged with nitrogen, was initially filled with 92 g of the diisocyanate of formula (II) (M-DIPI) under a nitrogen stream. 50 mg of 1-methylphosphene oxide were added and the mixture was heated to 160°C. Carbodiimidization (in which carbon dioxide is eliminated) is then carried out at 160° C. until an NCO content of about 1% by weight has been achieved. The product obtained at 160° was no longer stirrable. At 140°C the viscosity is >1000 Pas and thus granulation is not possible.

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com