Polyvinyl alcohol-based polymer film and method for producing the same

A polyvinyl alcohol-based, polymer film technology, applied in the field of optical films, can solve problems such as easy breakage, achieve high productivity, shorten drying time, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

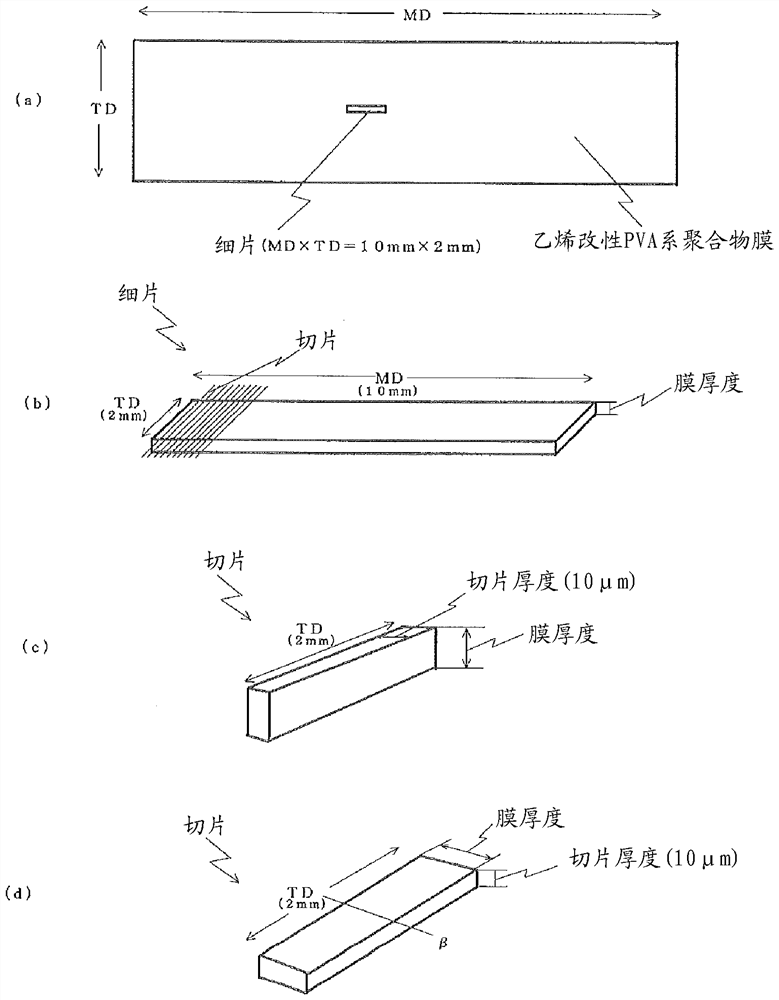

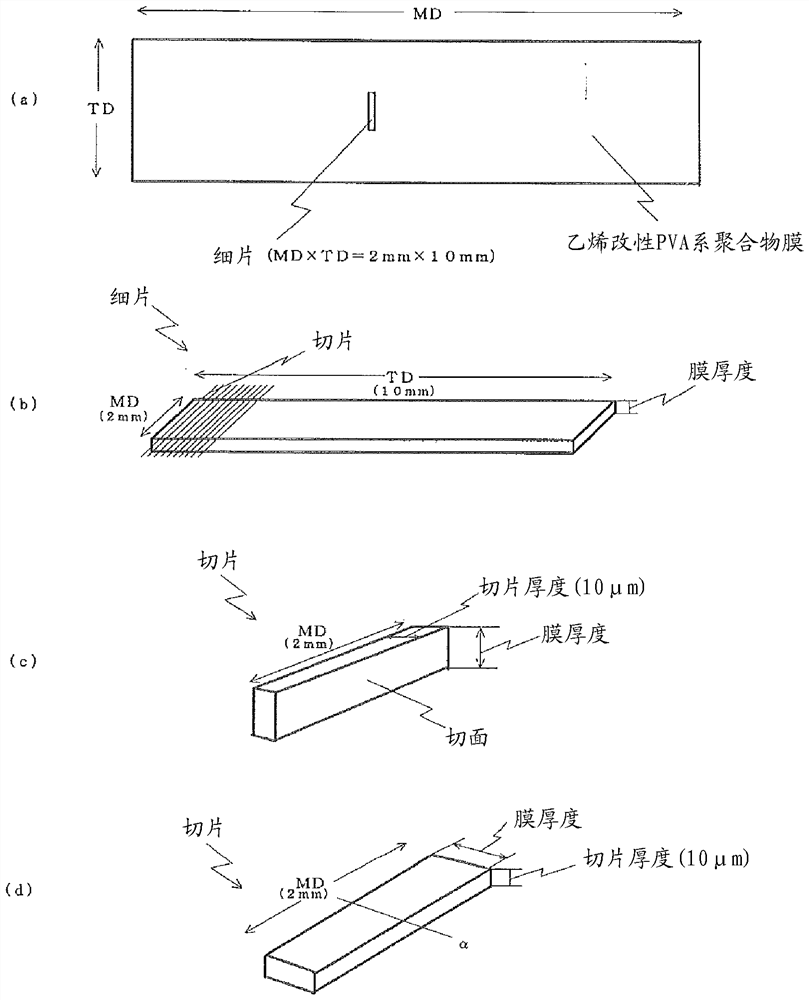

[0173] (1) Manufacture of PVA-based polymer film:

[0174] (i) 100 parts by mass of PVA obtained by saponification of polyvinyl acetate (saponification degree: 99.9 mol%, polymerization degree: 2400), 12 parts by mass of glycerin, 0.1 part by mass of lauric acid diethanolamide, and water and volatile matter The film-forming stock solution with a ratio of 66% by mass was passed from the T mold to the first drying roll of a film-forming device equipped with a plurality of drying rolls whose rotation axes were parallel to each other (the surface temperature was 93°C, and the peripheral speed (S 1 ) is 16.0m / min) to form a film, and on the first drying roller, blow hot air at 90°C at a wind speed of 5m / second to the entire non-contact surface of the first drying roller, while drying to volatile The ratio reaches 21% by mass, then peeled from the first drying roll, further dried with the second drying roll and subsequent drying rolls, and then heat-treated with a drying roll (heat ...

Embodiment 2、3 and comparative example 1~3

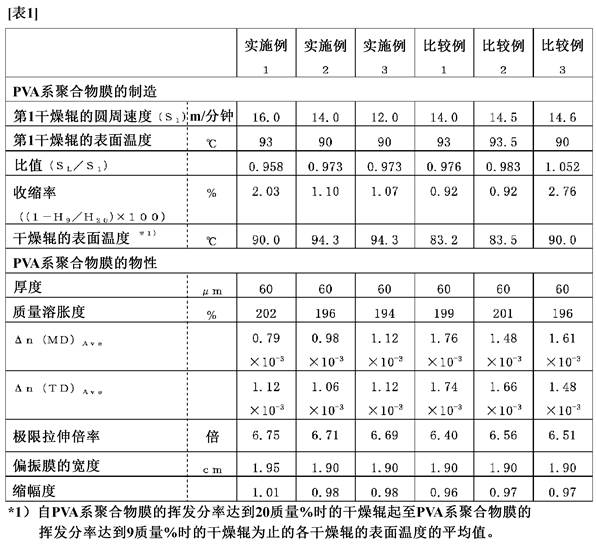

[0178] (1) In Example 1, the film formation conditions at the time of producing a PVA-type polymer film were changed as shown in following Table 1, and it carried out similarly to Example 1 (1), and produced the PVA-type polymer film.

[0179] The Δn(MD) of each PVA-based polymer film thus obtained was measured by the method described above. Ave , Δn(TD) Ave , mass swelling degree, ultimate stretch ratio and shrinkage range, as shown in Table 1 below.

[0180]

[0181] As shown in Table 1 above, it can be seen that by setting the Δn(MD) of the PVA-based polymer films of Examples 1 to 3 Ave [The value obtained by averaging the birefringence in the mechanical flow direction of the PVA-based polymer film in the thickness direction of the film] and Δn(TD) Ave[The value obtained by averaging the birefringence in the width direction of the PVA-based polymer film in the thickness direction of the film] satisfies the formulas (I) and (II), although stretching to a higher tensile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com