led flood light

A technology of LED floodlights and air vents, applied in the field of floodlights, can solve the problems of increased manufacturing cost, obstruction, and difficulty in obtaining heat dissipation effects, and achieve the effects of avoiding overheating, deterioration or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

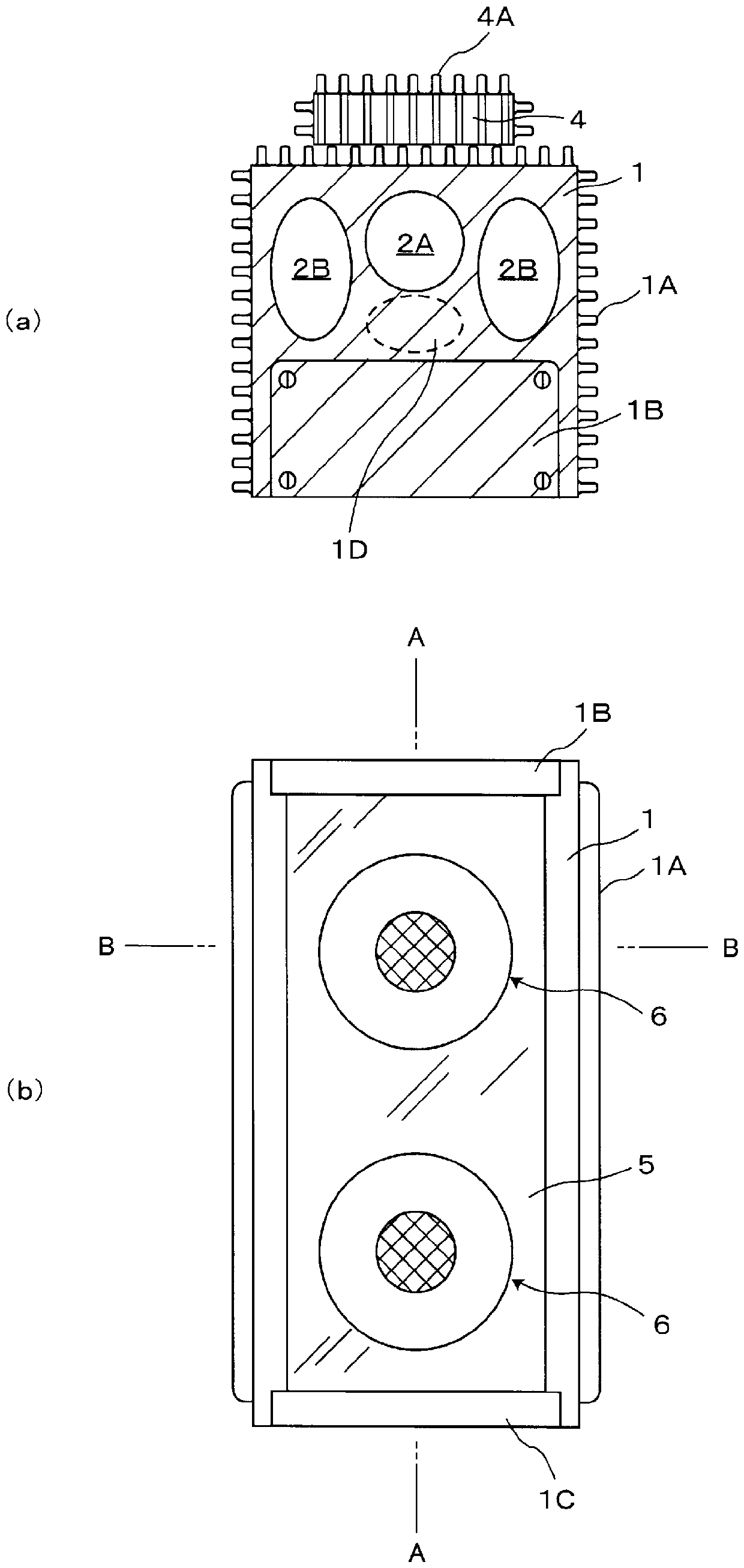

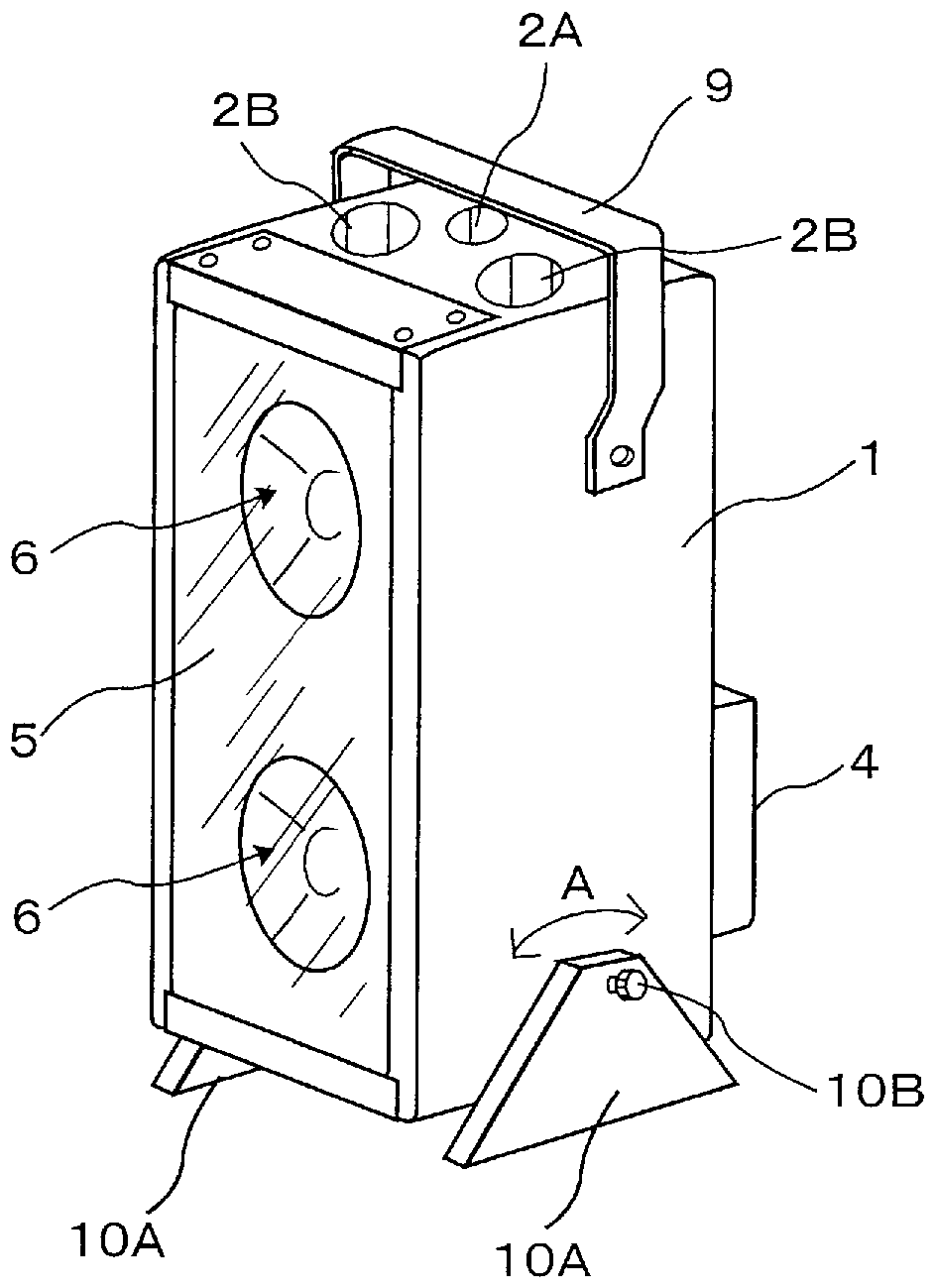

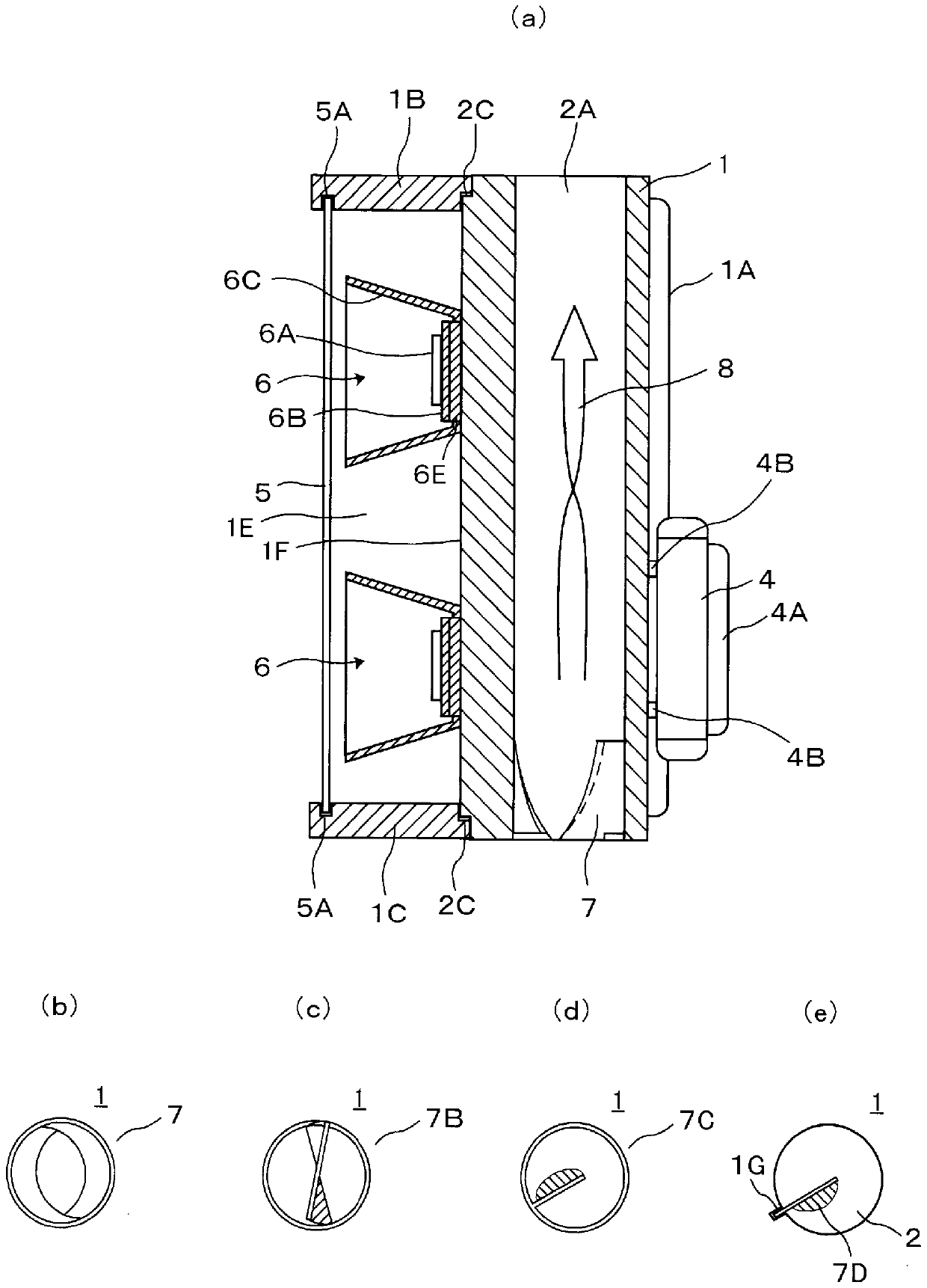

[0071] figure 1 Embodiment 1 of the LED floodlight of this invention is demonstrated, (a) is a top view, (b) is a front view. also, figure 2 right figure 1 Example 1 of the shown LED floodlight will be described, (a) is a right side view, and (b) is a bottom view. image 3 is along figure 1 (a) Cross-sectional view of line A-A. Such as figure 1 , figure 2 and image 3 As shown, regarding the LED floodlight of Example 1 of the present invention, an opening formed vertically by extruding a bulk material of aluminum as a metal material and having a groove 1E on one side is produced. The main body 1 of the groove 1E has a U-shaped cross-section perpendicular to the extrusion direction (longitudinal direction) of the extrusion molding. In the present embodiment, two LED units 6 are fitted in the longitudinal direction at the central portion viewed in the transverse section of the inner bottom wall 1F of the main body 1 formed as described above, in which the groove 1E is ...

Embodiment 2

[0081] Figure 4 It is an explanatory diagram of Embodiment 2 of the LED floodlight of the present invention, (a) is the same as image 3 In the same sectional views, (b) to (e) are plan views of the vent hole viewed from the lower end or upper end of the vent hole for explaining various structural examples of the drift unit. In this embodiment, most of its structures and functions are the same as those described above with reference to Figure 1 to Figure 3 The described Example 1 is the same, so the description will focus on the parts different from Example 1. FIG. In Embodiment 1, the vent hole 2 provided on the main body 1 has a structure in which the air flowing in from the opening at the lower end rises directly along the inner wall of the vent hole 2 and is discharged to the external environment through the opening at the upper end.

[0082] In Example 2, a deflector means is provided inside the vent hole 2 to provide a swirling or turbulent flow to the air flow 8 ris...

Embodiment 3

[0087] Figure 5 It is the description of Embodiment 3 of the LED floodlight of the present invention along the line corresponding to figure 1 (b) Cross-sectional view of the cutting line of the B-B line. In this embodiment, the configuration is such that three ventilation holes with the same cross-sectional area are provided in the main body 1, and the region 1D having a large heat capacity is arranged on the back of the inner bottom wall 1F of the main body 6, and three ventilation holes are used. 2A, 2B, and 2C surround this region 1D having a large heat capacity. Furthermore, inner fins or flow deflecting units may also be provided inside the vent hole 2 .

[0088] Heat generated from the light emitting portion 6A of the LED unit 6 is transmitted to the main body 1 through the substrate 6B and the insulating base plate 6E similarly to the above-described respective embodiments. The transferred heat is first absorbed by the region 1D having a large heat capacity, suppres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com