Process for producing white layered film, and white layered polyester film

A manufacturing method, white layer technology, applied in the field of white film, achieves the effect of less quality change and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

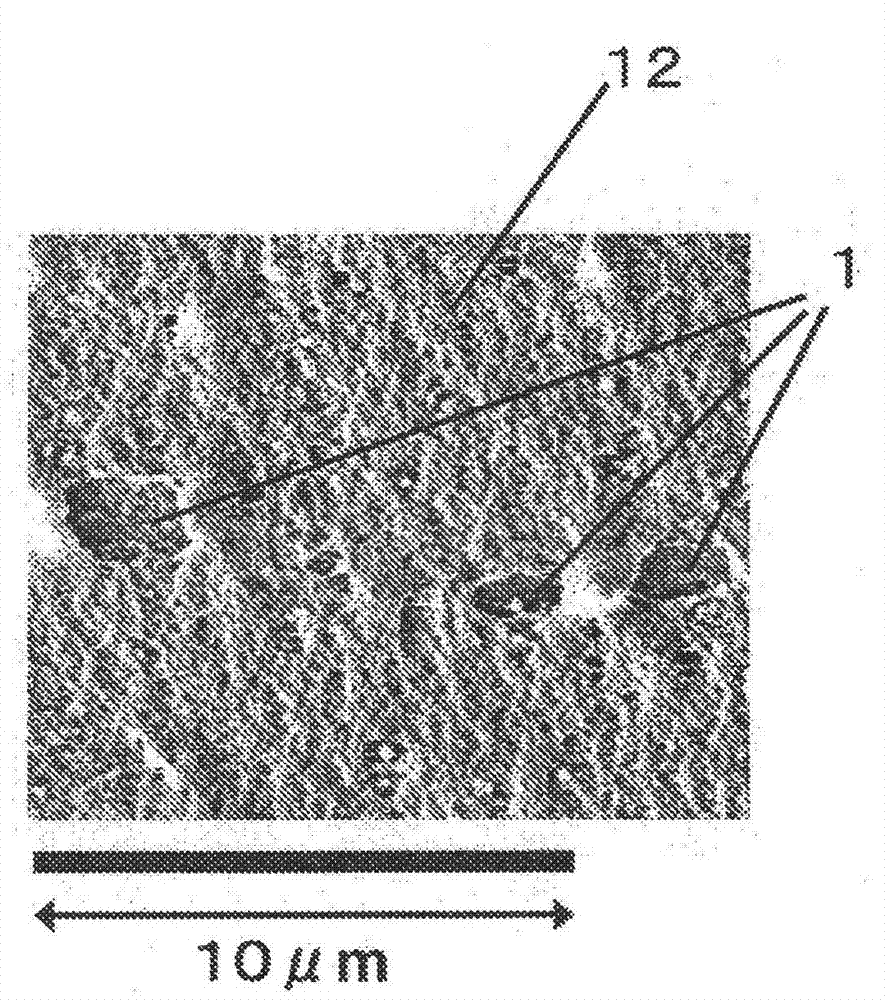

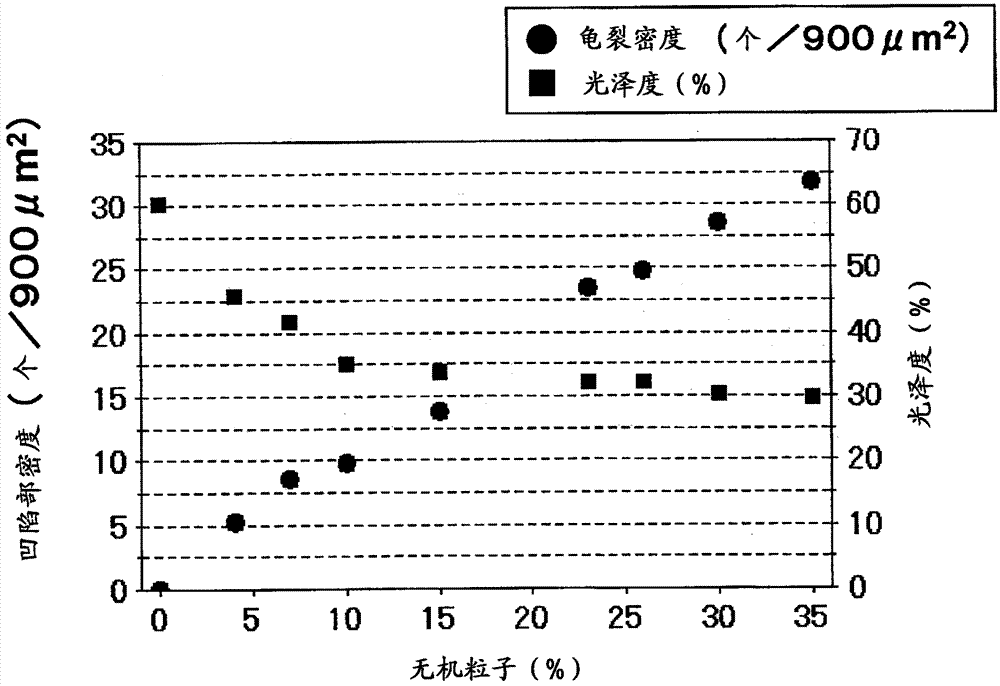

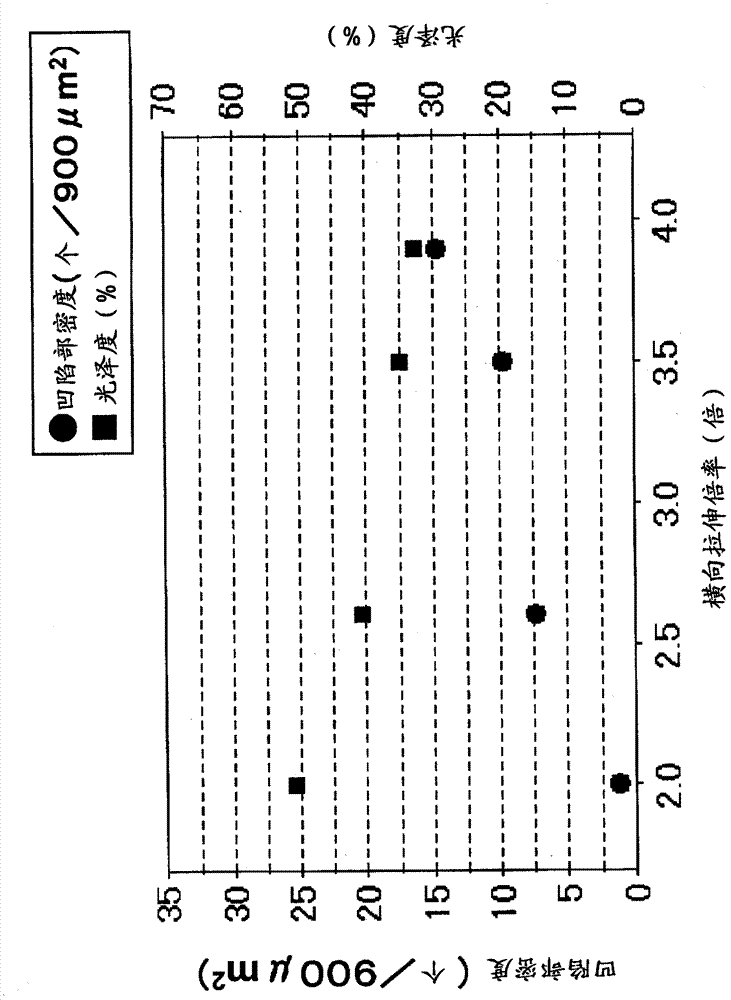

Image

Examples

Embodiment 1

[0207] The mixture of raw materials shown in Tables 1 to 4 was vacuum-dried at a temperature of 180°C for 3 hours, then supplied to an extruder, melted and extruded at a temperature of 280°C, filtered with a 30 μm cut filter, and then introduced into T mold nozzle.

[0208]Then, it is extruded into a sheet form from a T-die nozzle to form a molten single-layer sheet, and the molten single-layer sheet is adhered to a drum whose surface temperature is kept at 25°C by electrostatic application method for cooling and solidification to obtain Unstretched monolayer film. Then, after preheating the unstretched single-layer film with the roll group heated to 70° C., it was heated from both sides by an infrared heater (output 1.4 kW, distance from the film 15 mm, irradiation time 0.72 seconds). While being irradiated, it was stretched to 3.6 times in the longitudinal direction (longitudinal direction), and cooled with a roll set at a temperature of 25° C. to obtain a uniaxially stretc...

Embodiment 2~31

[0214] A film was prepared in the same manner as in Example 1 according to the film composition, production conditions, and coating liquid composition shown in Tables 1 and 3. Table 5 shows the evaluation results of physical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com