Method for protecting fine pattern and depositing metal layer using back exposure technology

A technology of backside exposure and metal layer, applied in microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problems of consistent patterns and difficult patterns, and achieve the effect of saving manufacturing time and cost, and reducing film stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

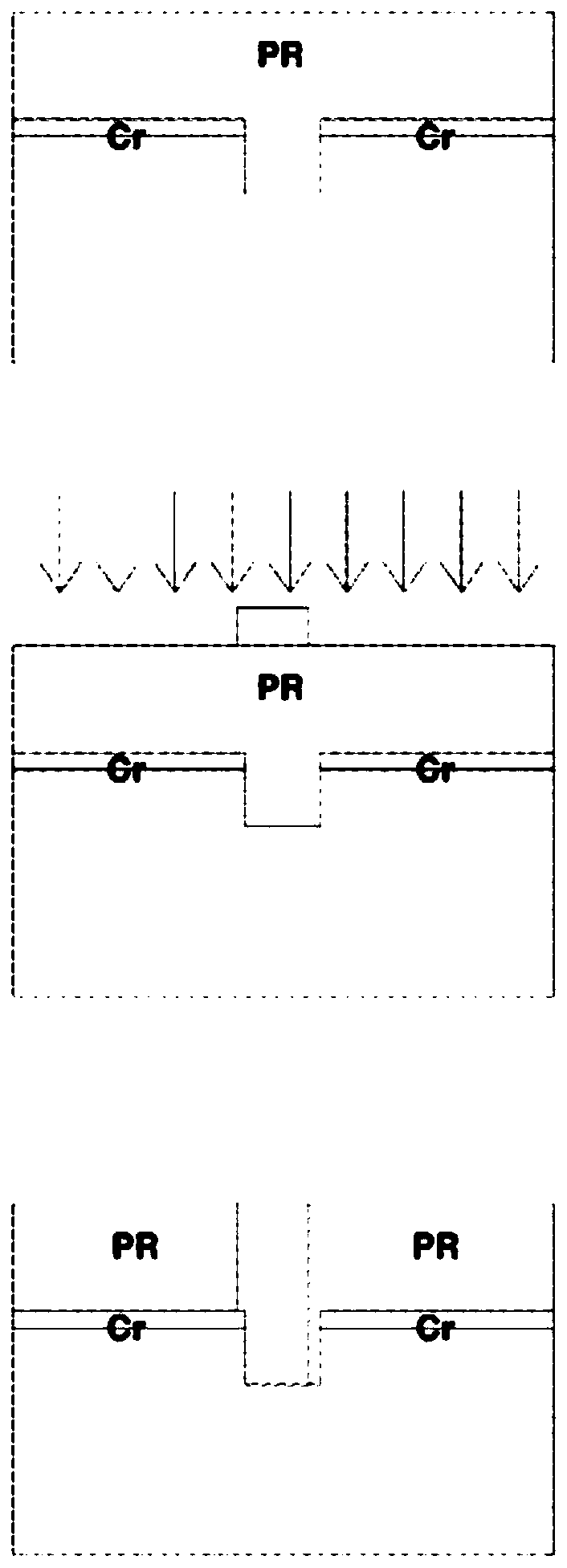

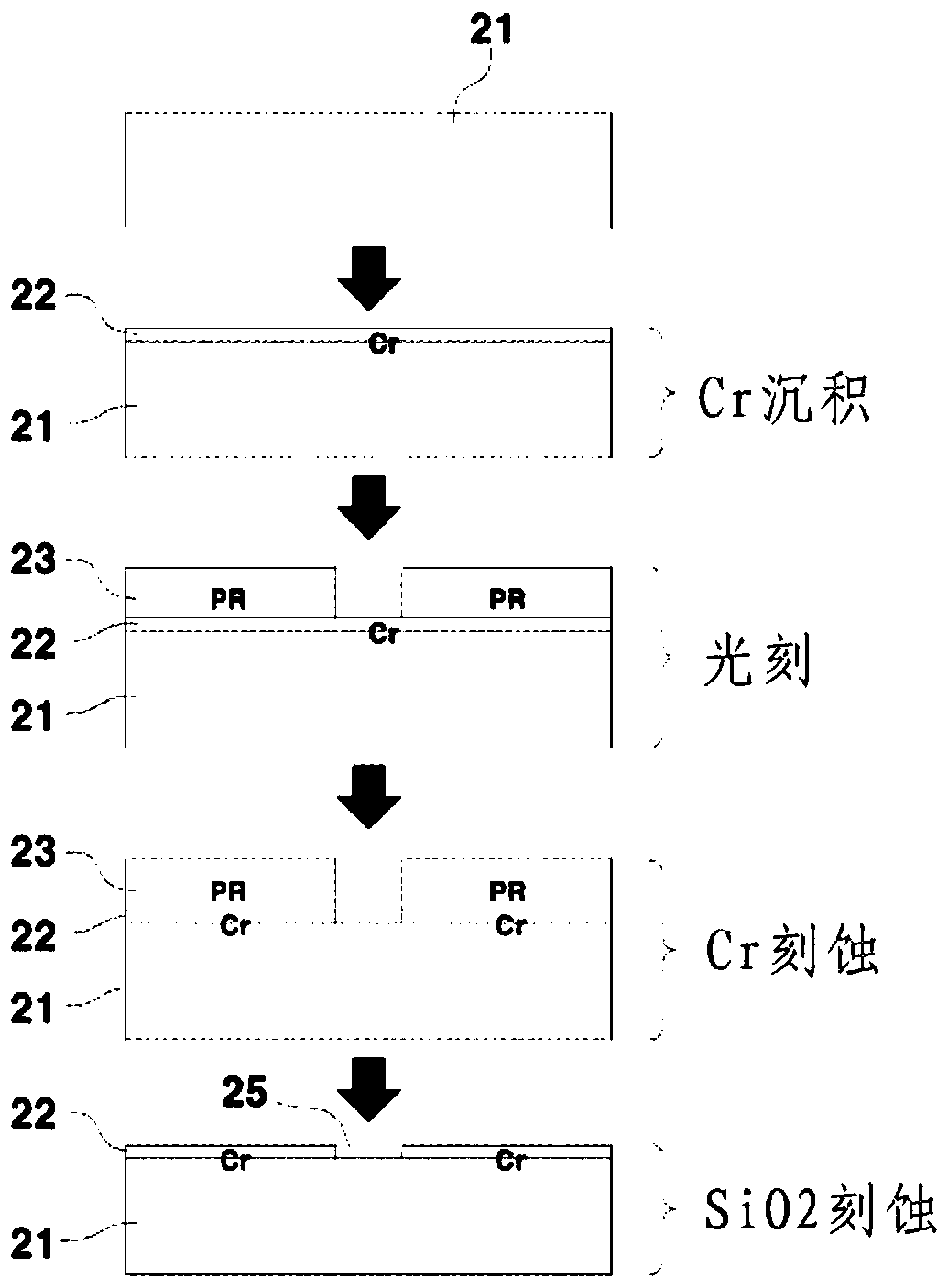

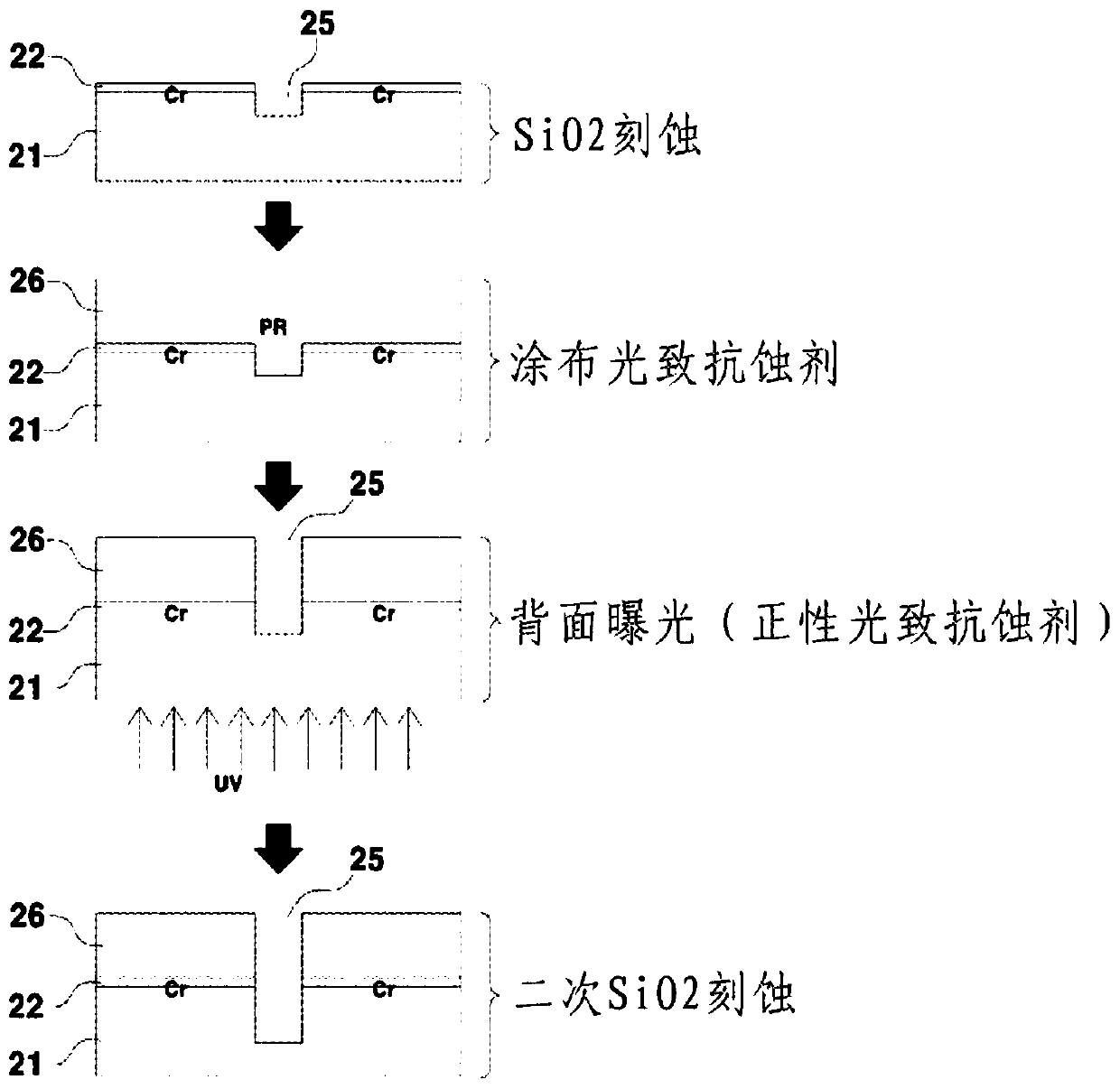

[0077] Through the above-mentioned backside exposure process of the optical element and the like of the present invention, the fine pattern of the optical element can be protected, and at the same time, the metal mask layer can be easily deposited. The following are related examples.

[0078] That is, the transparent substrate 21 is preferentially prepared. Such a transparent substrate 21 forms a photoresist, a metal layer, etc. substantially on the upper surface, and constitutes a base of components.

[0079]And, as shown in the figures and the following description, elements such as optical elements, semiconductor layers, and display panels are manufactured through a plurality of processes. Therefore, the present invention implements back exposure in this process, so that additional processing of the pattern holes formed on the transparent substrate can be realized, and the metal layer can be easily formed again on the upper part of the metal layer, while having the advantag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com