Deodorizing and sterilizing device for making shoes

A technology for sterilization equipment and shoes, applied in footwear, application, shoe-making machinery, etc., can solve the problems of time-consuming and laborious, low deodorization and sterilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

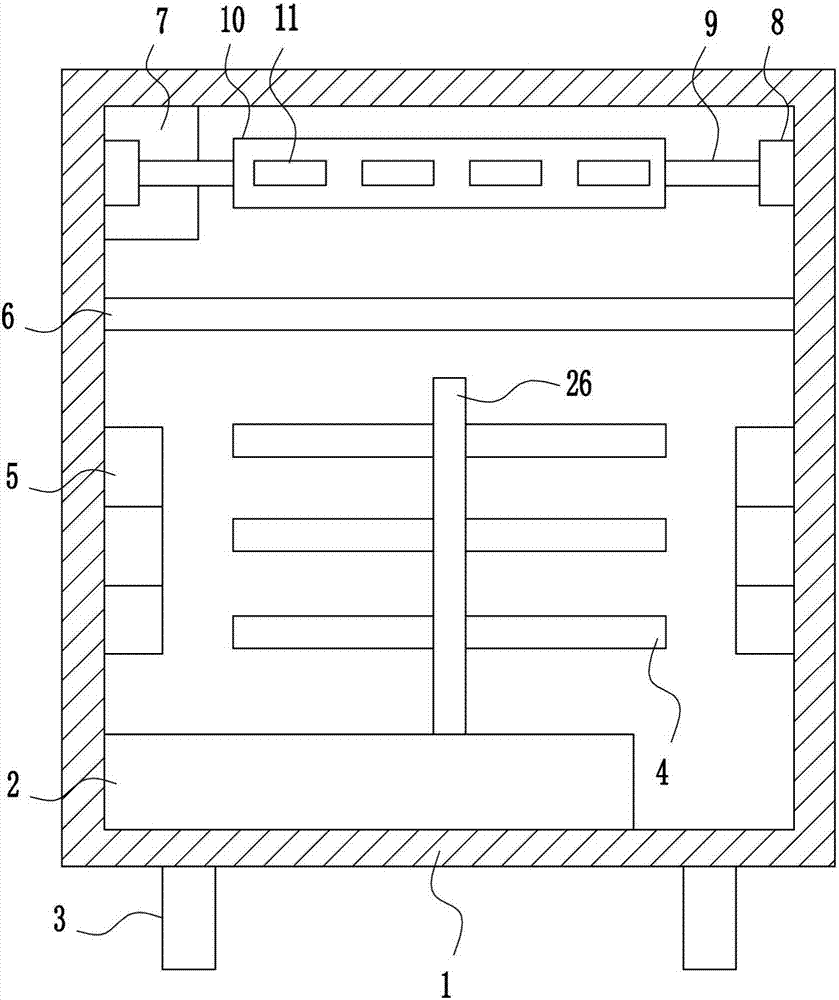

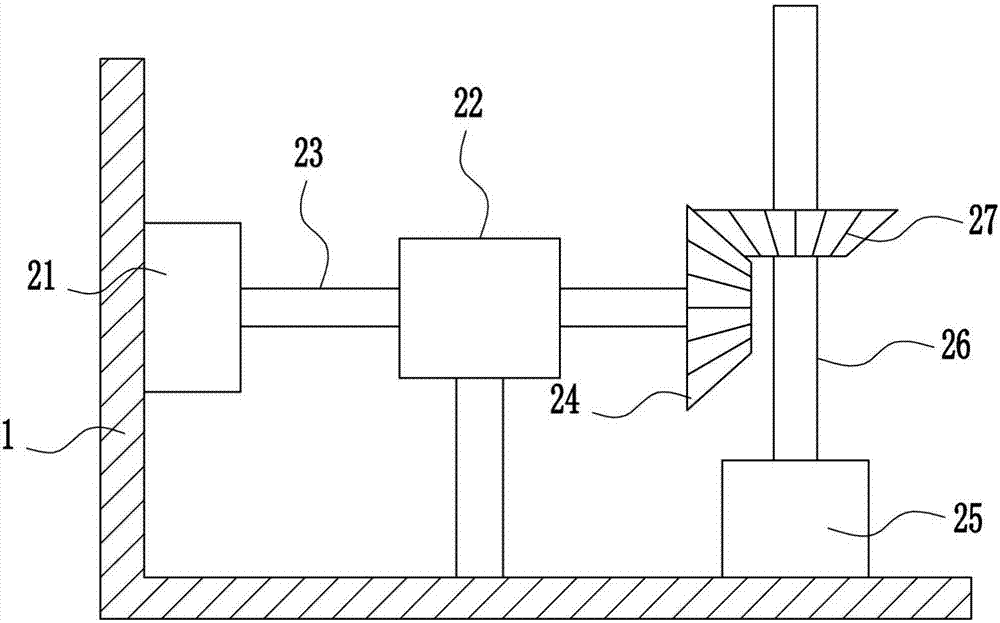

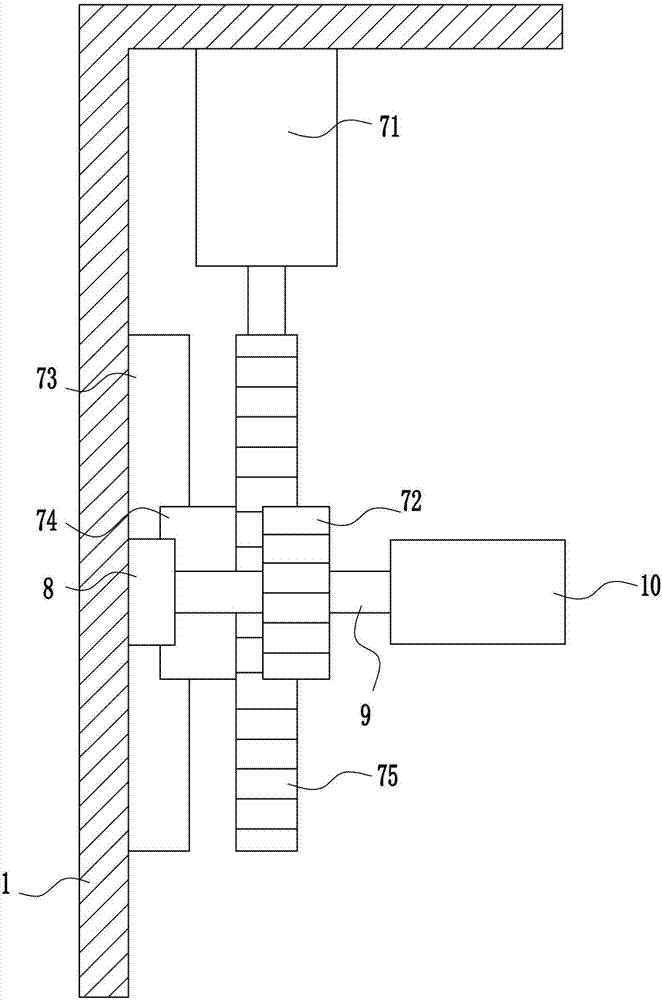

[0030] A kind of deodorizing and sterilizing equipment for making shoes, such as Figure 1-4As shown, it includes a housing 1, a first rotating device 2, a support rod 3, a placement plate 4, an ozone generator 5, a photocatalyst filter plate 6, a second rotating device 7, a first bearing seat 8, a second rotating shaft 9, The lamp holder 10 and the ultraviolet lamp 11 are welded with the first rotating device 2 on the upper left side of the inner bottom of the housing 1, the first rotating device 2 is connected with the first rotating shaft 26, and the left and right sides of the first rotating shaft 26 are evenly welded with the placement plate 4 The left and right sides below the bottom of the housing 1 are symmetrically welded with support rods 3, the middle part of the left and right walls of the housing 1 is symmetrically connected with an ozone generator 5 by means of bolt connection, and a photocatalyst filter plate is welded between the left and right walls of the hous...

Embodiment 2

[0032] A kind of deodorizing and sterilizing equipment for making shoes, such as Figure 1-4 As shown, it includes a housing 1, a first rotating device 2, a support rod 3, a placement plate 4, an ozone generator 5, a photocatalyst filter plate 6, a second rotating device 7, a first bearing seat 8, a second rotating shaft 9, The lamp holder 10 and the ultraviolet lamp 11 are welded with the first rotating device 2 on the upper left side of the inner bottom of the housing 1, the first rotating device 2 is connected with the first rotating shaft 26, and the left and right sides of the first rotating shaft 26 are evenly welded with the placement plate 4 The left and right sides below the bottom of the housing 1 are symmetrically welded with support rods 3, the middle part of the left and right walls of the housing 1 is symmetrically connected with an ozone generator 5 by means of bolt connection, and a photocatalyst filter plate is welded between the left and right walls of the hou...

Embodiment 3

[0035] A kind of deodorizing and sterilizing equipment for making shoes, such as Figure 1-4 As shown, it includes a housing 1, a first rotating device 2, a support rod 3, a placement plate 4, an ozone generator 5, a photocatalyst filter plate 6, a second rotating device 7, a first bearing seat 8, a second rotating shaft 9, The lamp holder 10 and the ultraviolet lamp 11 are welded with the first rotating device 2 on the upper left side of the inner bottom of the housing 1, the first rotating device 2 is connected with the first rotating shaft 26, and the left and right sides of the first rotating shaft 26 are evenly welded with the placement plate 4 The left and right sides below the bottom of the housing 1 are symmetrically welded with support rods 3, the middle part of the left and right walls of the housing 1 is symmetrically connected with an ozone generator 5 by means of bolt connection, and a photocatalyst filter plate is welded between the left and right walls of the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com