Filtering cloth cleaning device and filter press

A cleaning device and filter cloth technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, can solve the problems of low work intensity, low cleaning efficiency, high work intensity, etc., to reduce work intensity, improve utilization efficiency, The effect of improving water spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

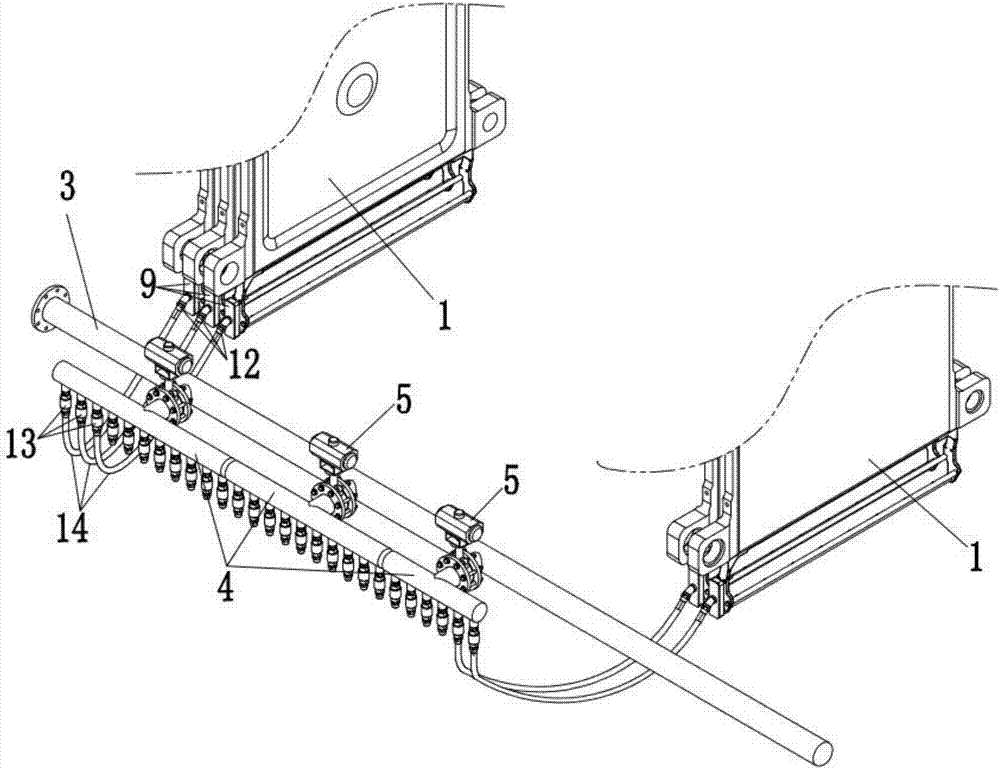

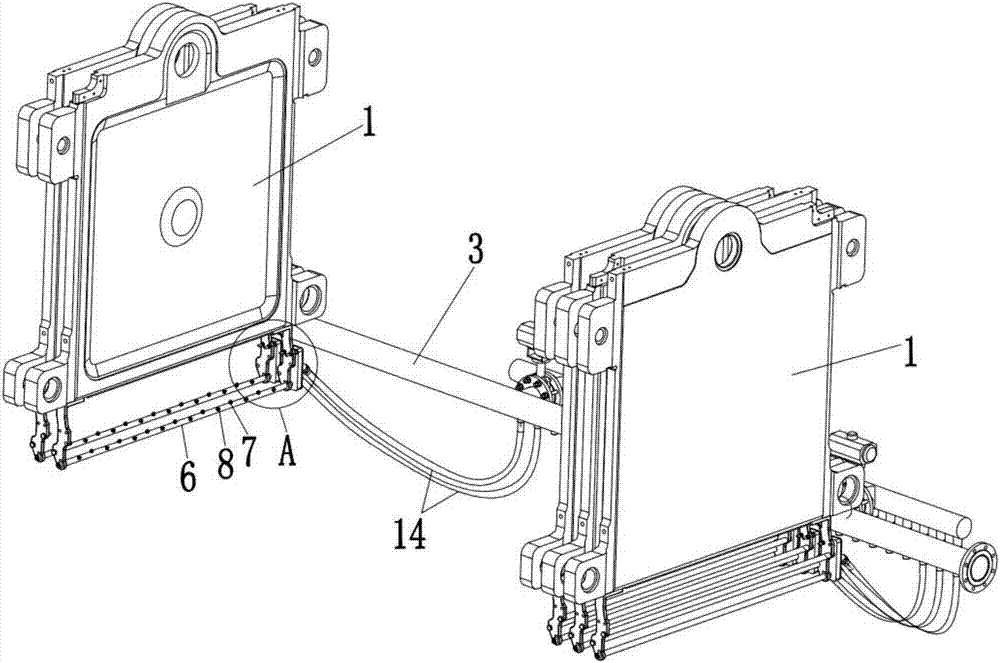

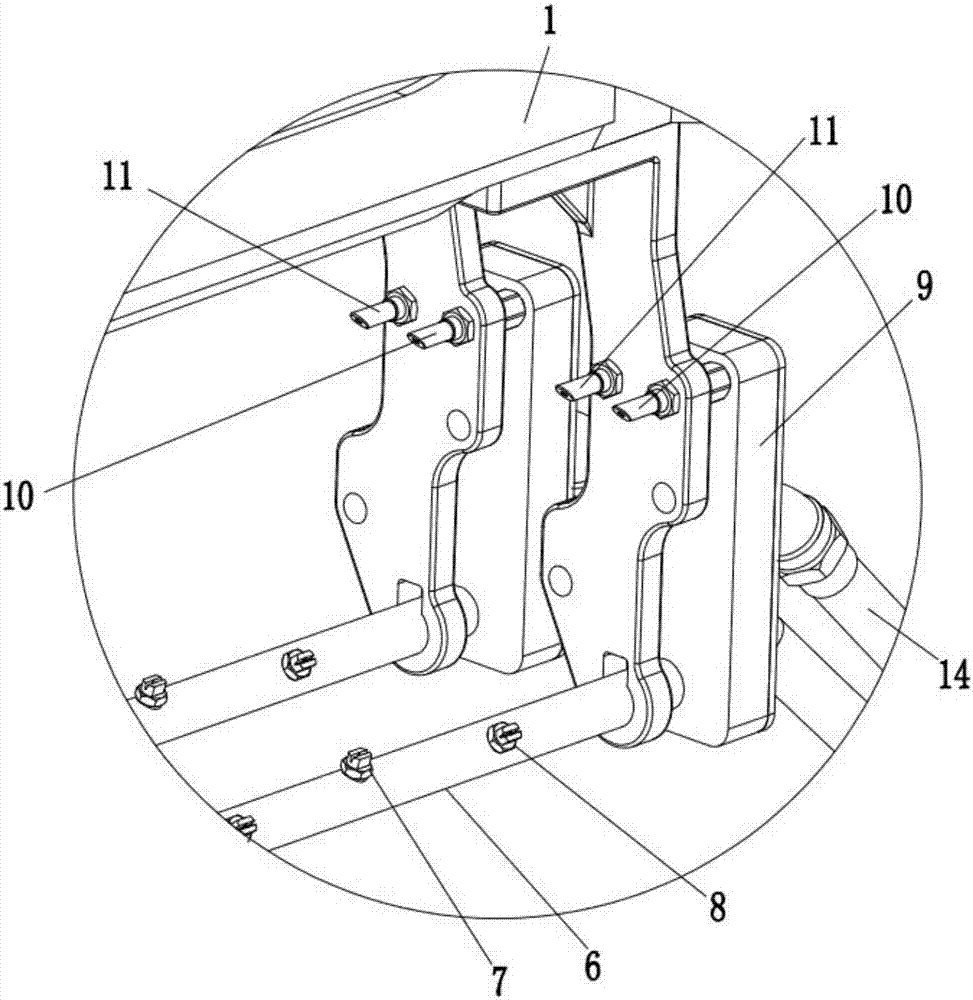

[0032] like figure 1 As shown, the filter cloth cleaning device of this embodiment includes a high-pressure water supply pump, a water supply channel connected with the high-pressure water supply pump, and a water spray structure connected with the water supply channel to spray the filter cloth 2 The water supply channel includes a main water supply pipe 3 and a plurality of auxiliary water supply pipes 4 communicated with the main water supply pipe 3 through a control structure, and the water spray structure includes several spray nozzles communicated with the auxiliary water supply pipe 4 through a communication structure. Water pipe 6, and several nozzle assemblies arranged at intervals on the water spray pipe 6; wherein, the water spray pipe 6 is arranged at the lower end of the filter plate 1 and its length direction is consistent with the width direction of the filter cloth 2 When cleaning, the control structure communicates with the main water supply pipe 3 and the auxi...

Embodiment 2

[0047] On the basis of Embodiment 1, this embodiment further provides a filter press, which includes the above-mentioned filter cloth cleaning device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com