Soy sauce pouring equipment

A technology for soy sauce and equipment, which is applied in the field of soy sauce drench equipment, can solve the problems of low production efficiency, time-consuming and labor-intensive, etc., and achieve the effects of uniform spraying, easy dredging, and promotion of wine production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

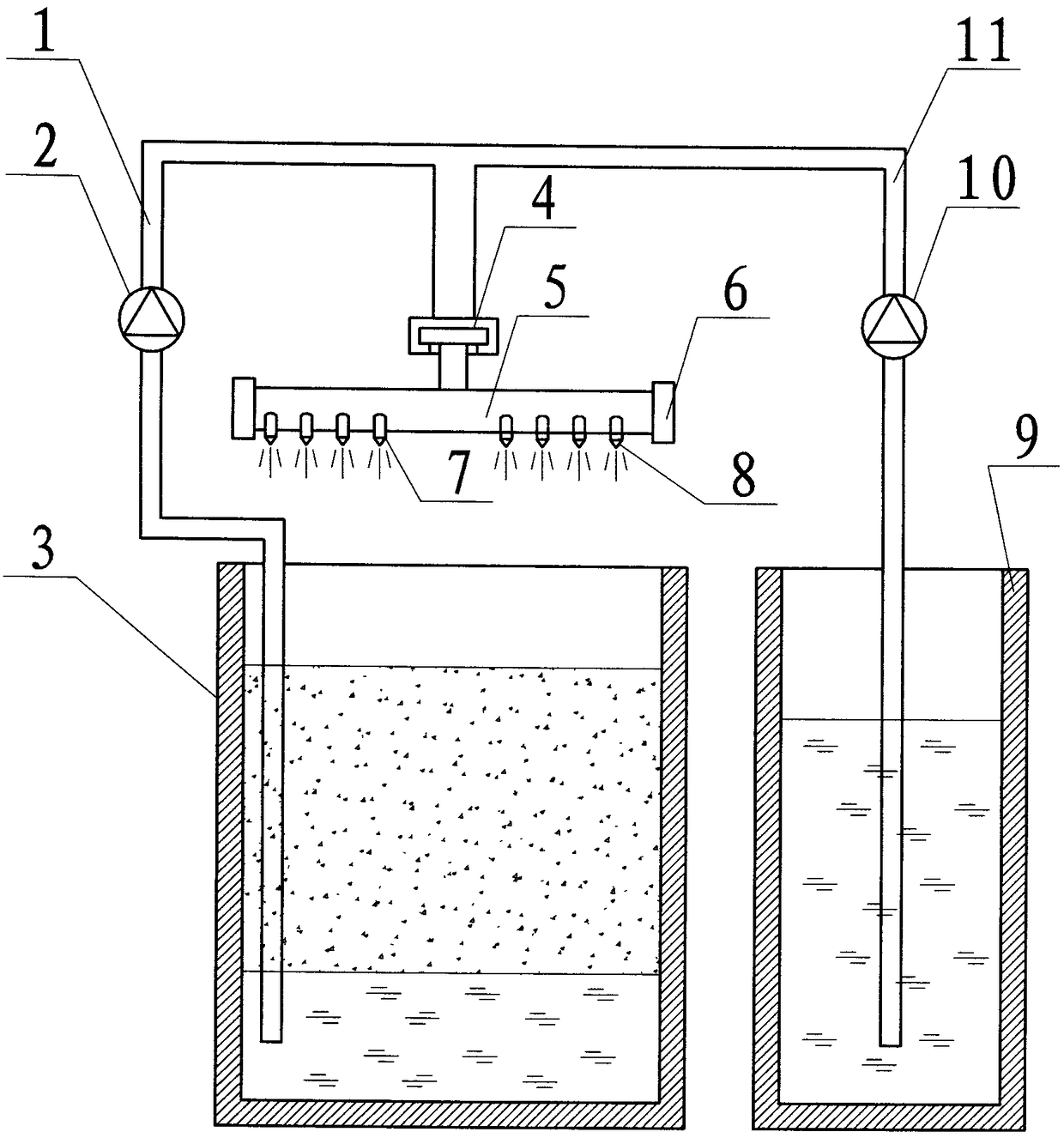

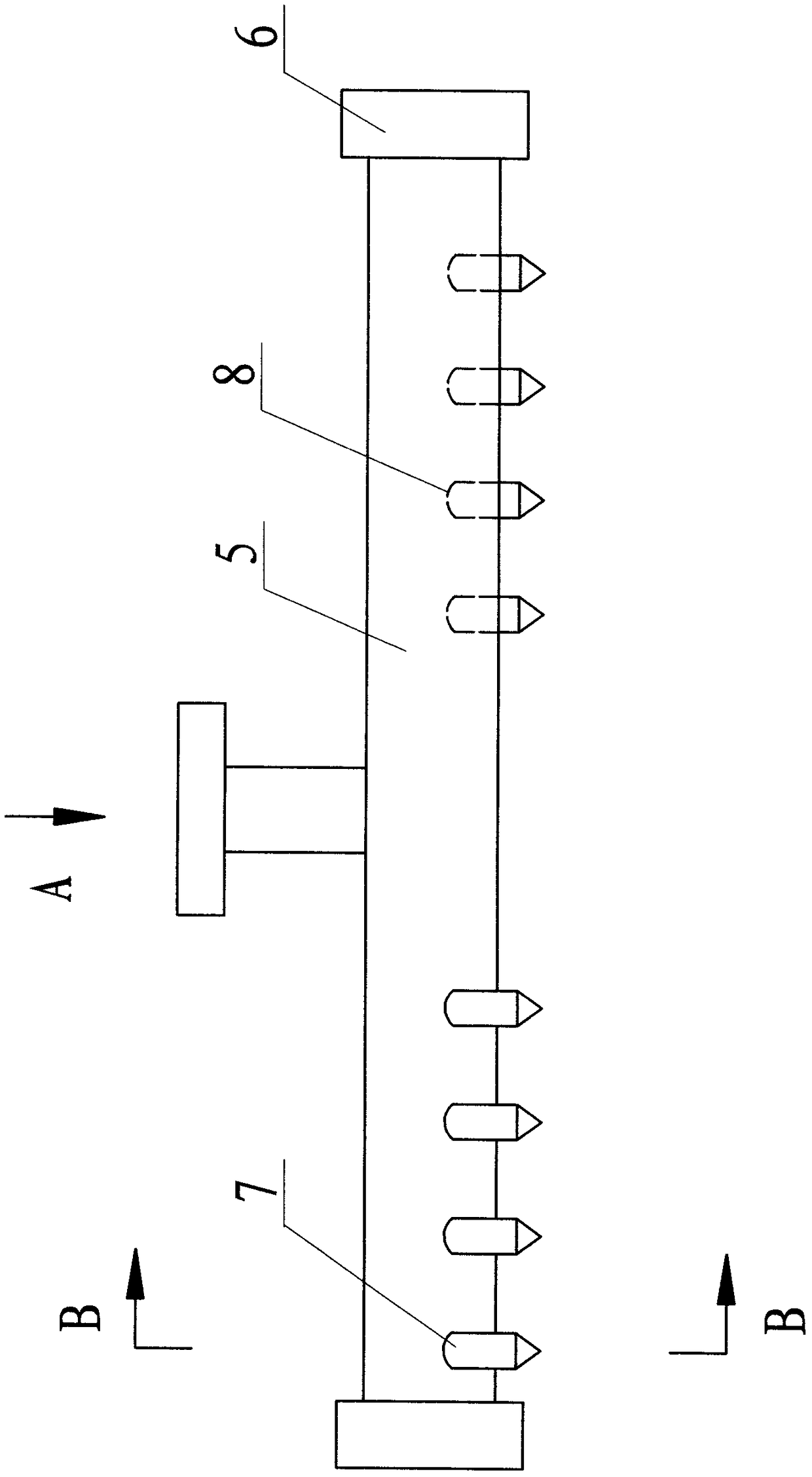

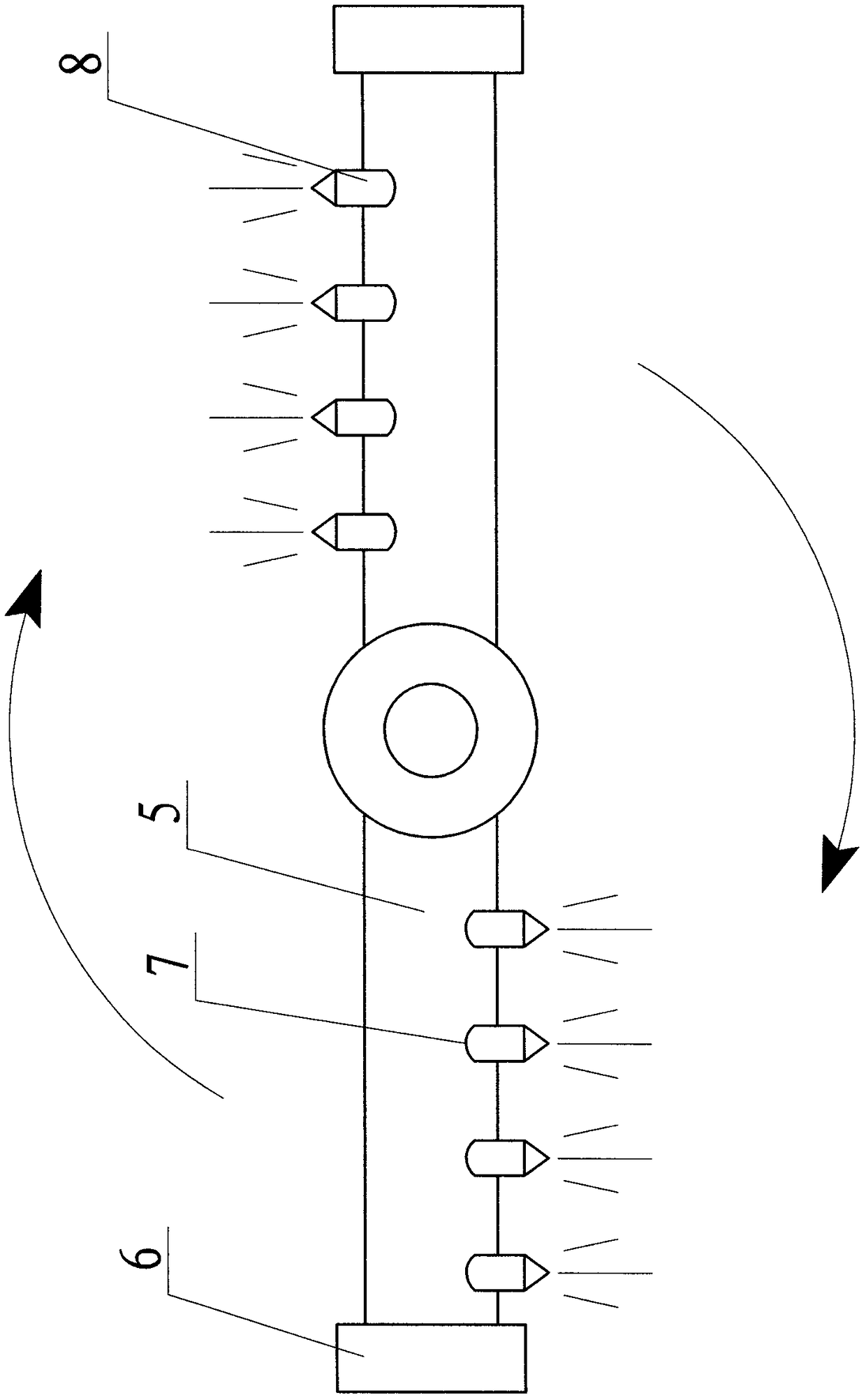

[0027] like figure 1 As shown, in the present invention, the main pump 2 is installed on the main pipe 1 , the auxiliary pump 10 is installed on the auxiliary pipe 11 , and the auxiliary pipe 11 communicates with the main pipe 1 . The main pipe 1 communicates with the middle part of the shower pipe 5 in a hinged manner through the rotating shaft 4, and the shower pipe 5 can freely rotate around the hinge point. The length of the return shower pipe 5 is slightly less than the diameter of the soy sauce fermenter 3, preventing the oil from being sprayed outside the tank and causing waste. Set dredging valves 6 at both ends of the return shower pipe 5. After the equipment has been used for a period of time, the dredging valves 6 at both ends can be opened to allow oil to flow out from both ends, which is convenient for dredging and equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com