Additive and subtractive composite 3D printing equipment and method for plasma multi-axis numerical control machine tool

A CNC machine tool and 3D printing technology, which is applied in the direction of additive processing, other manufacturing equipment/tools, and energy efficiency improvement, can solve the problems of low precision and low efficiency of workpieces, achieve high-efficiency compound processing of adding and subtracting materials, and increase the size Effects of precision and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The present invention will be described in further detail below in conjunction with specific embodiments.

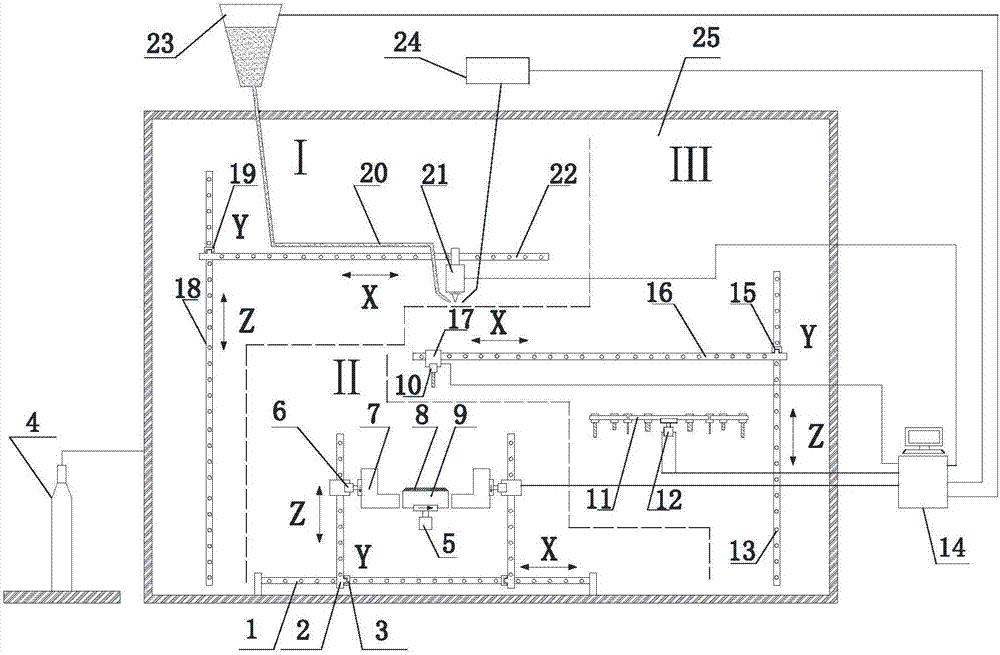

[0080] Such as Figures 1 to 7 shown. The invention discloses a plasma and multi-axis CNC machine tool addition and subtraction composite 3D printing equipment, including a central control system 14 and a sealed molding room 25;

[0081] The sealed molding chamber 25 is divided into: Zone I, Zone II and Zone III;

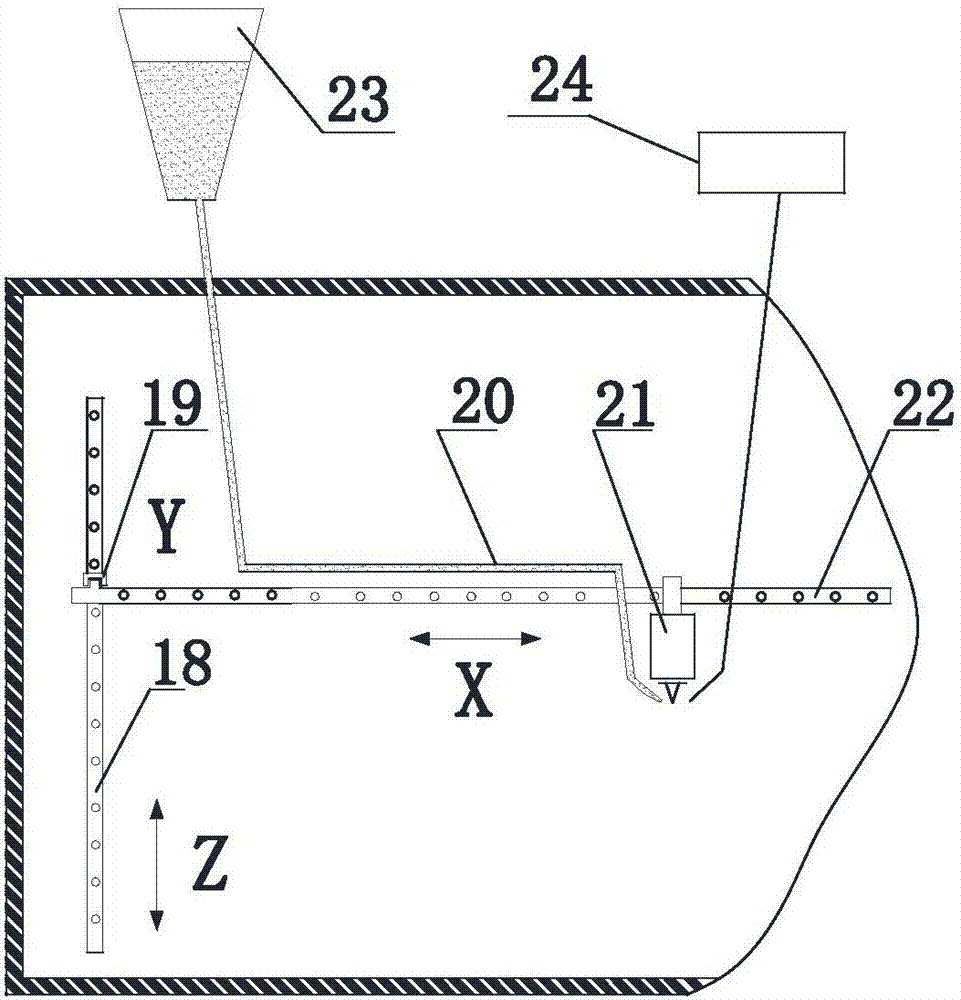

[0082] Area I is used to place micro-beam plasma processing devices;

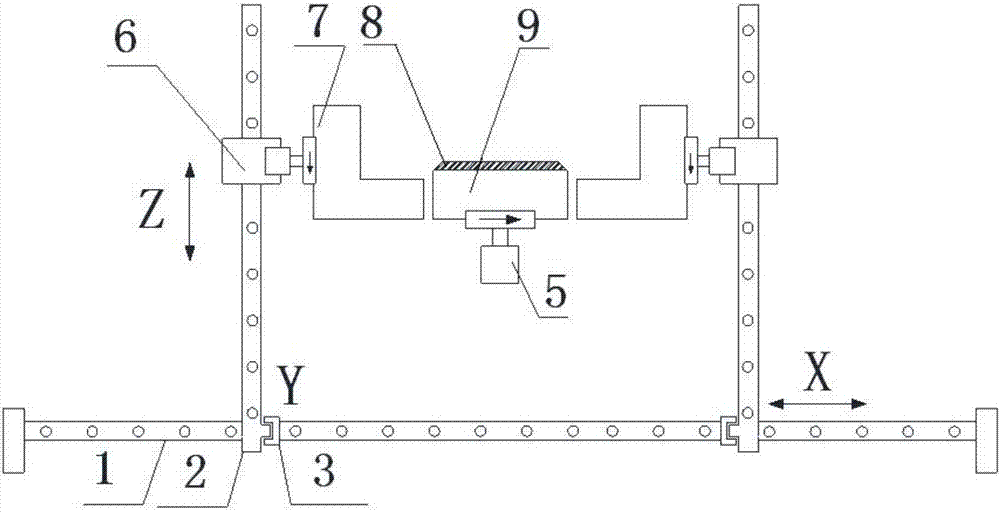

[0083] Area II is used to place five-axis five-linkage CNC machining platform;

[0084] Area III is used to place end milling and milling devices;

[0085] The central control system 14 is used to: control the micro-beam plasma processing device to complete the processing of the workpiece according to the planned path; control the five-axis and five-linkage CNC machining platform to realize the movement of the workpiece in the directions of X, Y, and Z axes according to the plann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap