Vertical-horizontal combined machining centre

A compound machining center, vertical and horizontal technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem that the structure of the machine tool cannot meet the requirements of high-efficiency precision machining, cannot perform left and right feed movement, and cannot perform up-and-down precision feed give exercise and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

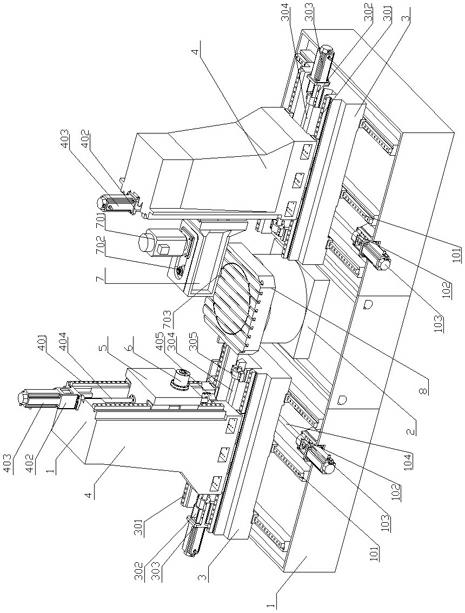

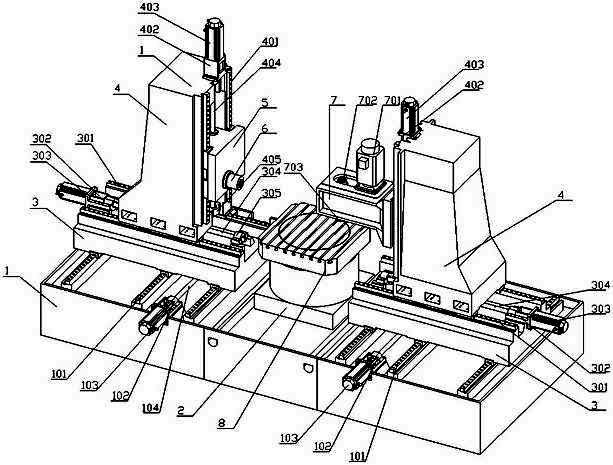

[0015] Embodiment: the vertical and horizontal compound machining center of this example, such as figure 1 , there is a base 1, a fixed workbench 2 is arranged in the middle of the base, and a numerical control rotary workbench 8 is installed on the fixed workbench 2. Three base slide rails 101 are fixed on the bases at both ends of the fixed workbench, and a sliding seat 3 that can move forward and backward is slidably connected to the base slide rails at both ends. Base motor 103 is fixed with base motor seat 102 on the base, base motor is connected with base screw mandrel 104, base screw mandrel connects slide seat 3, and the other end of base screw mandrel is connected with base screw mandrel bearing seat, base screw mandrel nut seat, Bearings are arranged in the base screw bearing seat. Two sliding seats 3 are fixed with two sliding seat slide rails 301, and the sliding seat slide rails are slidably connected with uprights 4 that can slide left and right. Seat motor 303...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap