Compound tool for automobile piston processing

A composite cutting tool and automobile piston technology, which is applied in the field of mechanical processing equipment, can solve the problems of affecting product size stability, rapid cutting tool wear, and low production efficiency, and achieve the effects of simple structure, accurate cutting edge shape, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

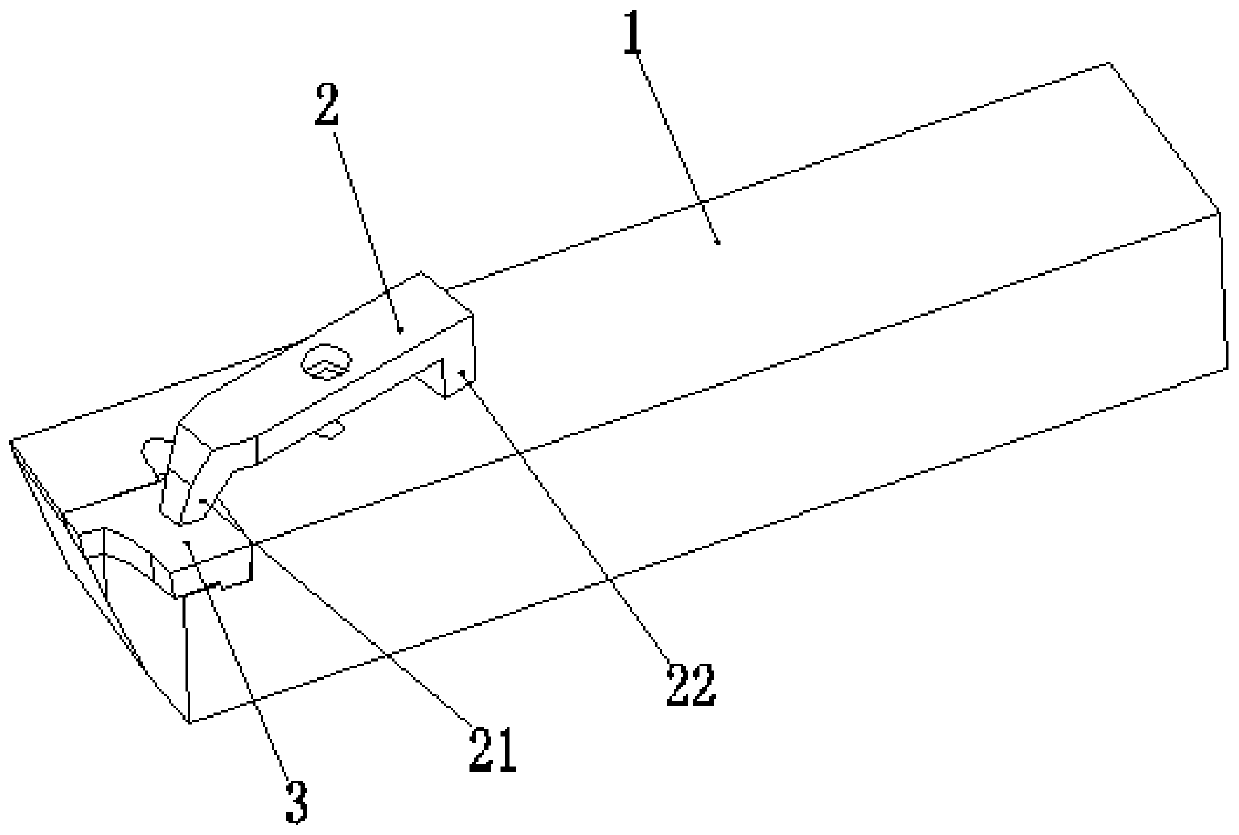

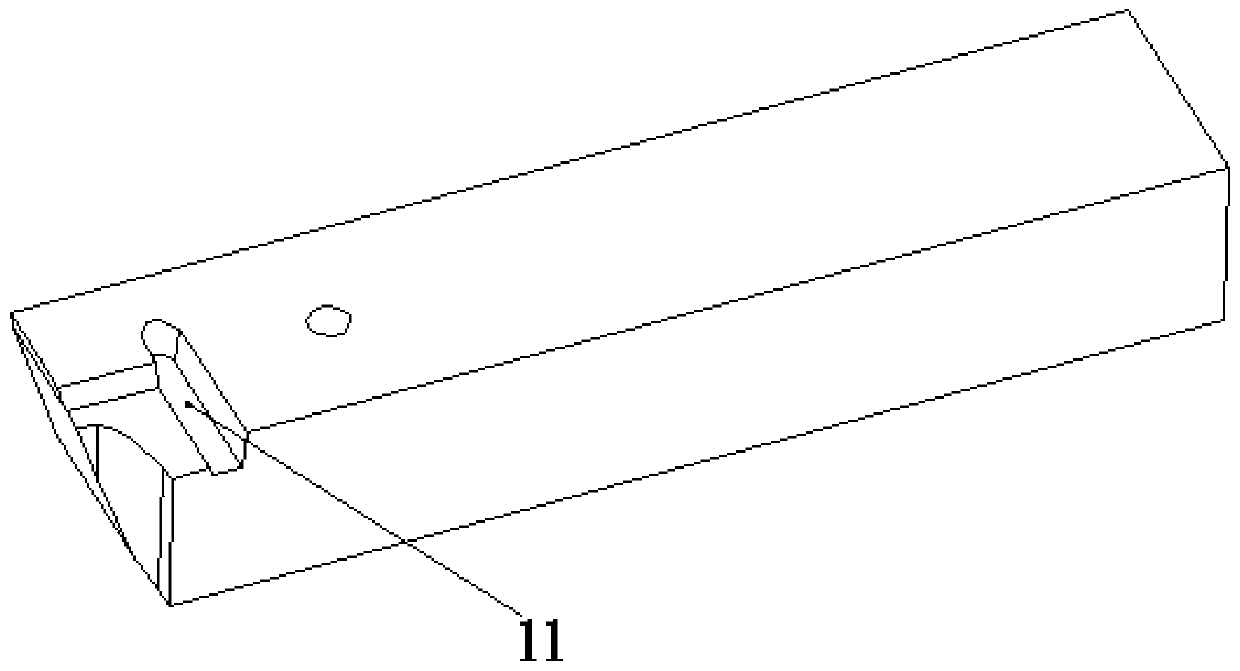

[0026] see Figure 1 to Figure 3 , the composite cutting tool for automobile piston processing in this embodiment is characterized in that it includes a handle, a blade and a clamping mechanism.

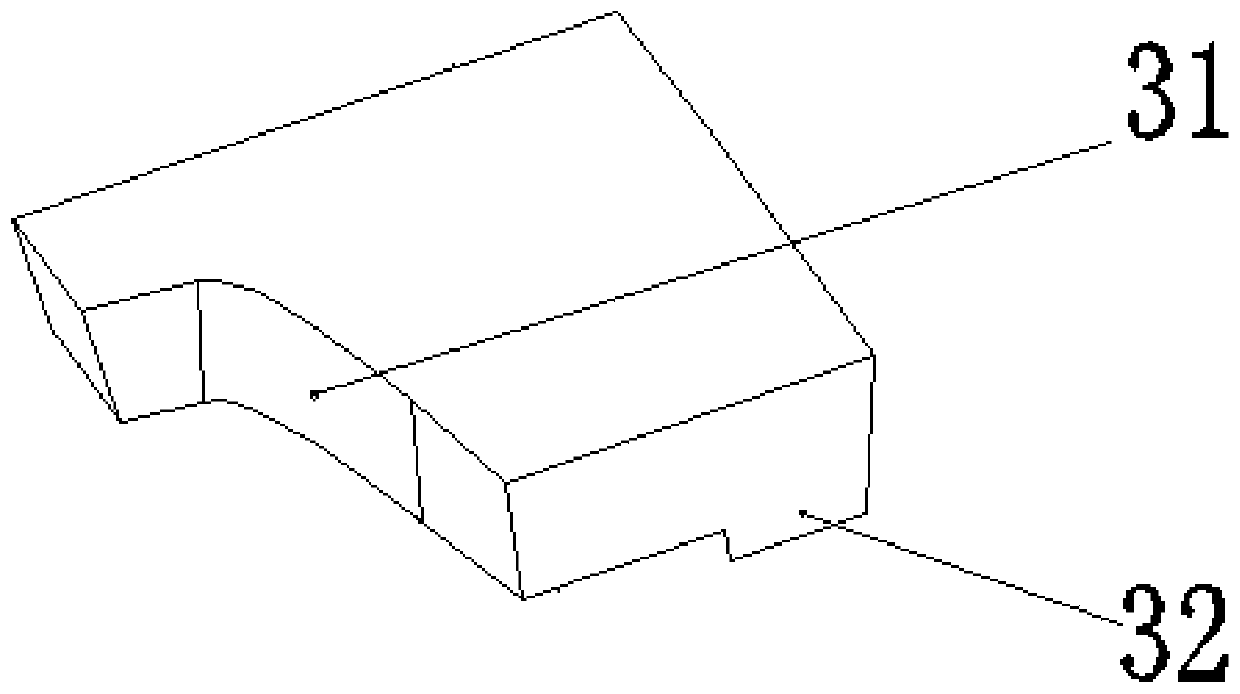

[0027] The clamping mechanism includes a clamping piece, a screw hole is provided on the clamping piece, and a contact portion and a clamping portion are respectively formed at both ends of the clamping piece, and a clip for clamping the blade in the axial direction is provided on the handle. The connecting groove and the threaded hole for fixing the holder, the bottom of the blade has a buckle strip that matches the buckle groove and is arranged on the end of the handle through the buckle strip so as to form a snap fit with the handle. The clamping part is connected to the knife handle by screws, and its clamping part is pressed against the blade and its contact part is pressed against the end surface of the knife handle. As a preference, the blade forms a composite deflection angl...

Embodiment 2

[0032] see Figure 4 , the content of this embodiment is substantially the same as that of Embodiment 1, the difference is that the handle 1 has a wedge-shaped boss 12 near the contact portion 22, the wedge-shaped boss 12 has an inclined surface, and the contact portion 22 has a The contact surface matched with the inclined surface abuts against the inclined surface of the wedge-shaped boss 12 through the contact surface. In addition, the clamping portion 21 is conical.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap