Material guiding and processing mechanism for thin film

A processing mechanism and film technology, applied in the direction of thin material processing, winding strips, sending objects, etc., can solve complex structure, inconsistent film unwinding speed and winding speed, and difficult to accurately control the amount of glue on the film surface and other problems, to achieve the effect of reasonable structural design, efficient and convenient pick-and-place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further describe the present invention, a specific implementation of a film guide processing mechanism will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

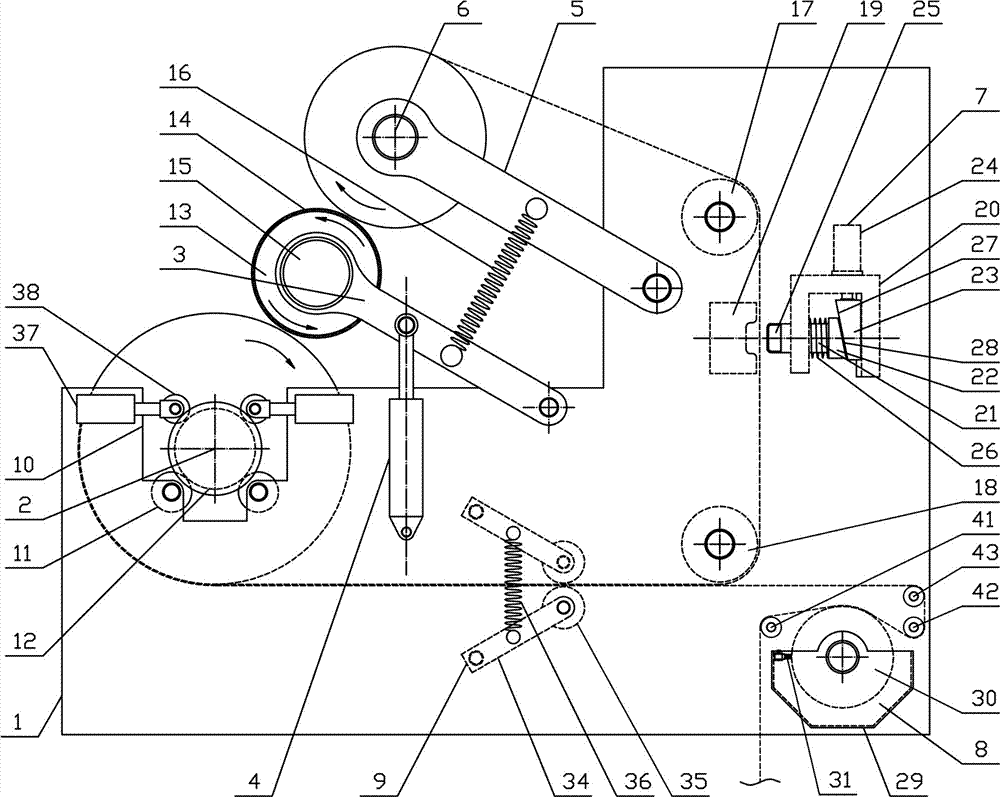

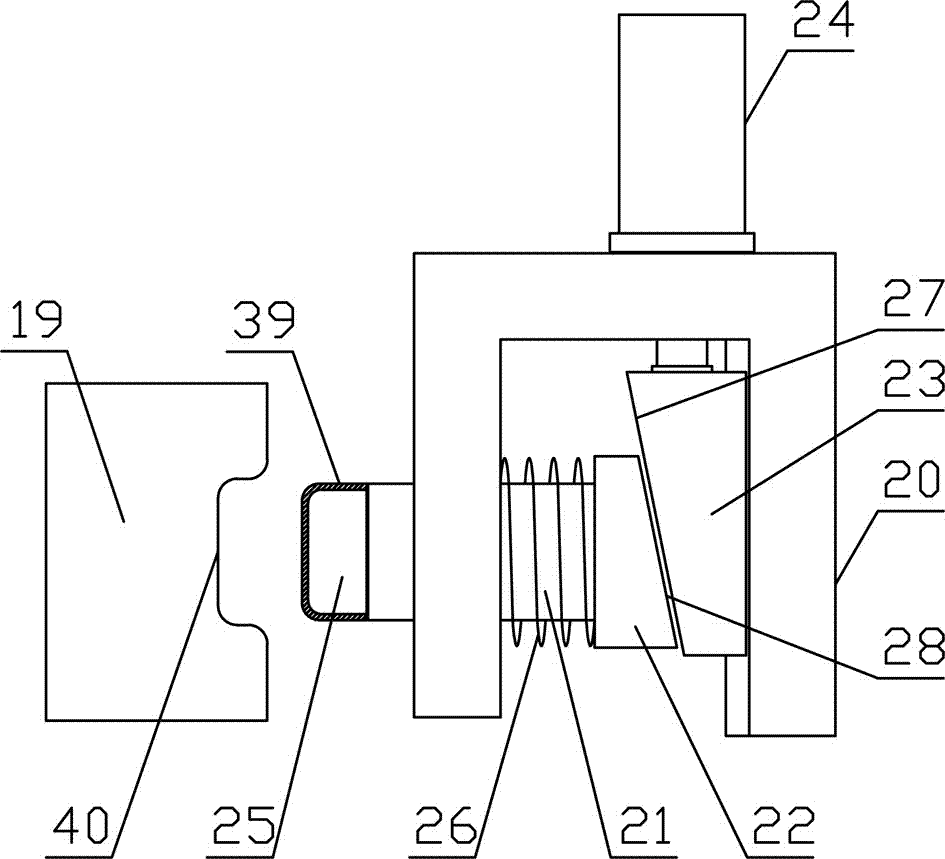

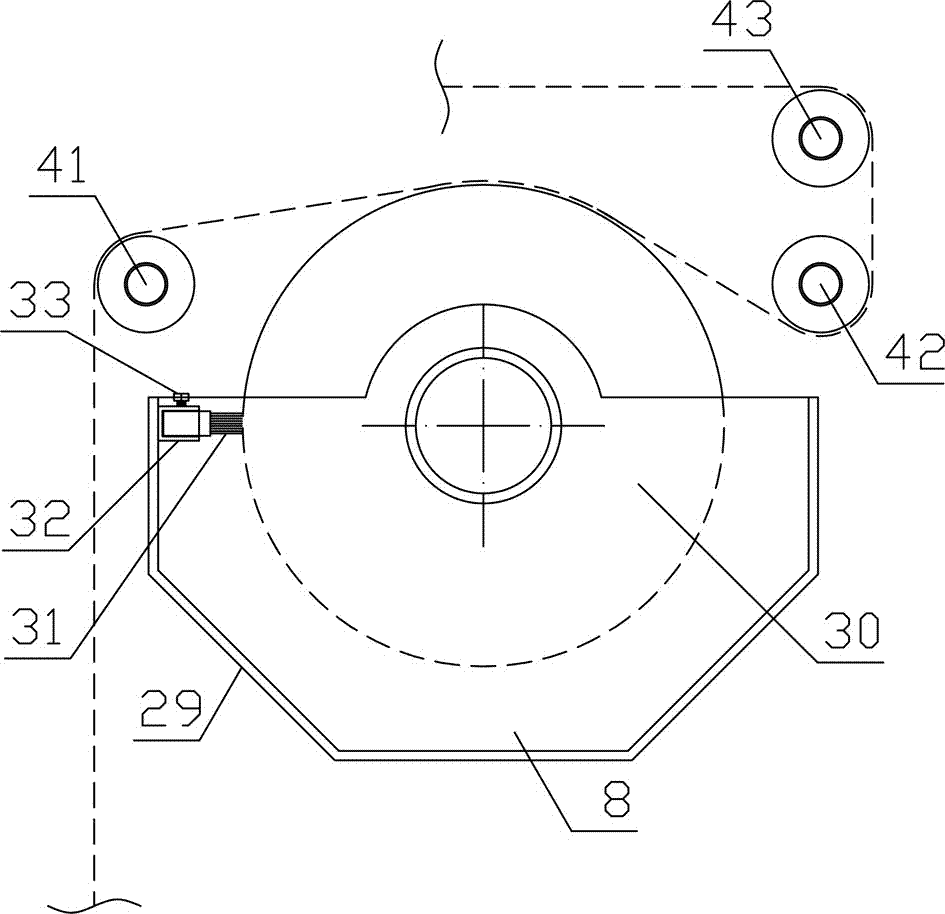

[0013] like figure 1 As shown, a film guiding material processing mechanism of the present invention comprises a material guiding bracket 1, a winding roller 2, a rotating bracket 3, a tension cylinder 4, an unwinding bracket 5, an unwinding roller 6, a film fixing mechanism 7, a gluing Mechanism 8 and laminating compound mechanism 9, unwinding support 5, rotating support 3 and winding roller 2 are arranged on one side of material guide support 1 in sequence from top to bottom, and film fixing mechanism 7 is horizontally arranged on the other side of material guide support 1 At the upper end, the gluing mechanism 8 is horizontally arranged at the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap