Pin extractor

A technology of pins and outer casings is applied in the field of pin lifters, which can solve the problems of difficult cylindrical pin extraction, damage to parts and complicated operations, and achieve the effects of preventing falling off, being convenient to use and simple to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

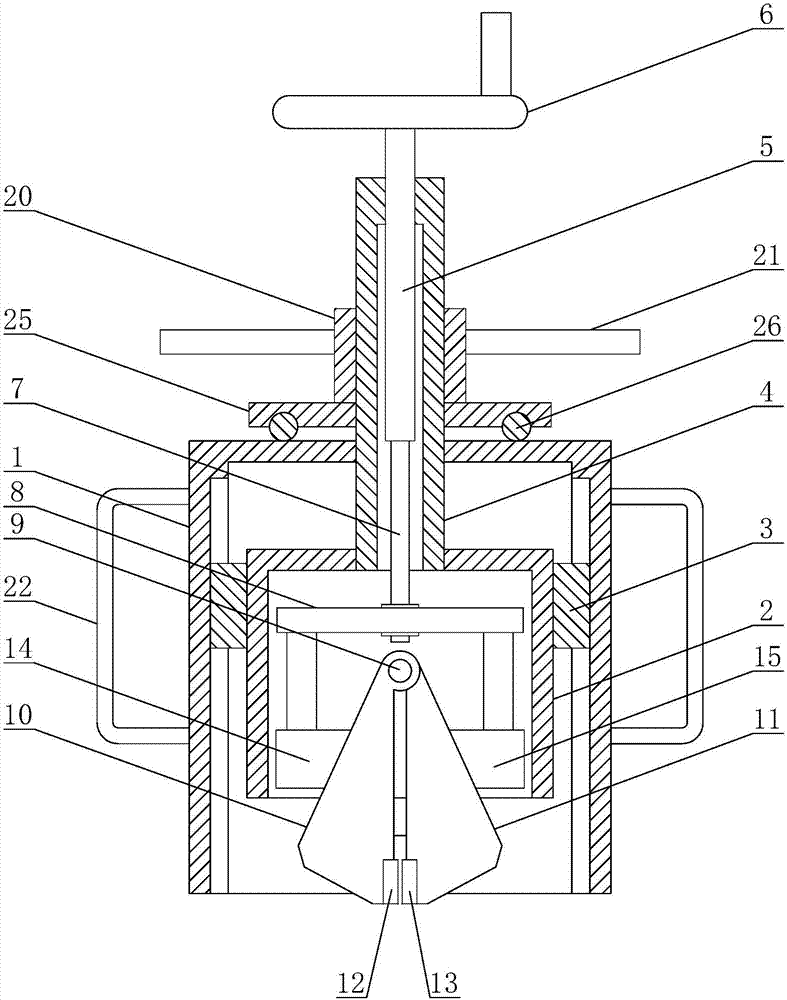

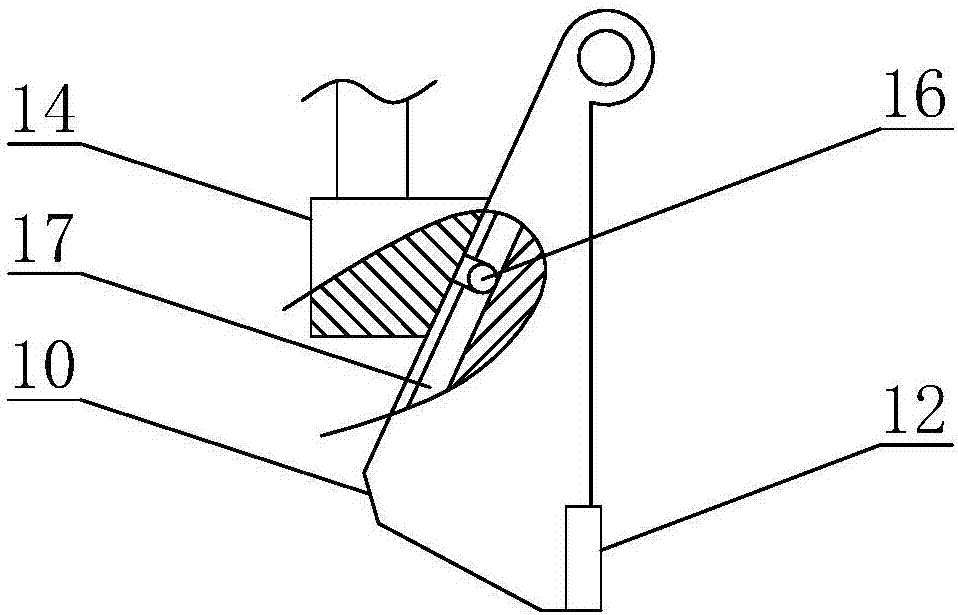

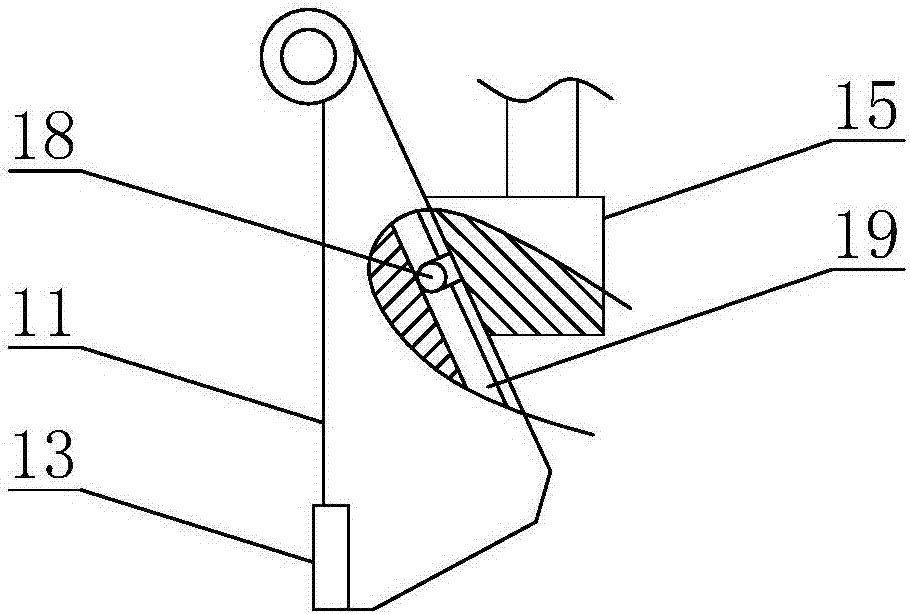

[0028] Embodiment: The present invention is a pin extractor, which includes an outer shell 1, and a handle 22 is welded on the outer wall of the outer shell 1, which can facilitate the carrying of the present invention and the use of the present invention. The outer shell 1 is provided with an inner shell 2, the outer wall of the inner shell 2 is provided with two sliders 3, and the inner wall of the outer shell 1 is provided with a chute adapted to the slider 3, The inner casing 2 is slidingly connected with the outer casing 1 . One end of the outer casing 1 is provided with an opening compatible with the inner casing 2, and the inner casing 2 can extend out of the outer casing 1 through the opening. The end of the inner casing 2 away from the opening is welded with a support cylinder 4 , and the support cylinder 4 communicates with the inner casing 2 . The end of the outer shell 1 away from the opening is provided with a through hole adapted to the support cylinder 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com