Melt mixing mechanism for PVC thermal shrinkage film

A technology of melt mixing and heat-shrinkable film, which is applied to flat products, household appliances, and other household appliances, etc. It can solve the problems of film product thickness difference, multiple equipment, uneven coloring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

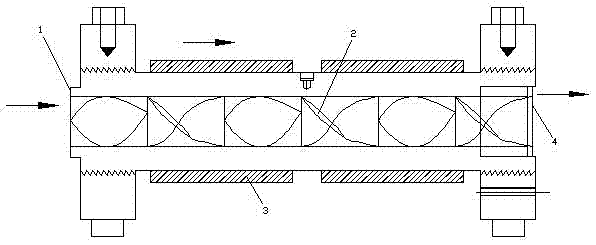

[0013] A PVC heat shrinkable film melt mixing mechanism, the melt mixing mechanism includes an extruder 1, a film blowing head 4 and a static mixer, and a static mixing is set between the extruder 1 and the film blowing head 4 One end of the static mixer is combined with the screw head of the extruder 1, and the other end of the static mixer is connected with the connecting section of the film blowing head 4 through a flange. The static mixer is composed of several series connected with each other The twisted elements 2 are composed of the twisted elements 2 fixedly arranged in the barrel of the extruder 1, and the twisted elements 2 are interlaced with each other to form an angle of 90°, and the diameter of the static mixer is the same as that of the extruder 1 The inner diameters of the barrels are the same, and a strip heater 3 is arranged outside the barrel of the extruder 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap