Uniform material distributing device and method adaptable to various kinds of materials

A technology for evenly distributing materials and materials, applied in the directions of packaging, transportation and packaging, loading/unloading, etc., can solve the problems of poor adaptability, short service life, low productivity, etc., and achieve the effect of good adaptability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments. The embodiments described below are exemplary, and are only used to explain the present invention, but should not be construed as limiting the present invention. Where specific techniques or conditions are not indicated in the examples, the procedures shall be carried out in accordance with the techniques or conditions described in the literature in the field or in accordance with the product specification.

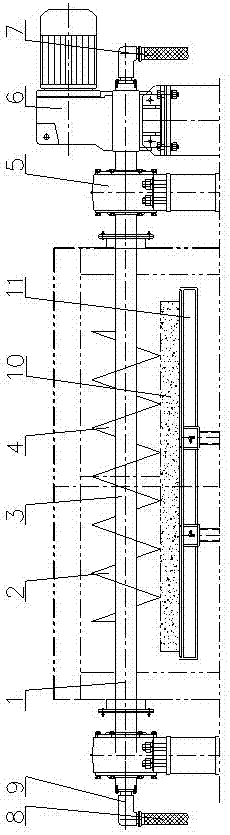

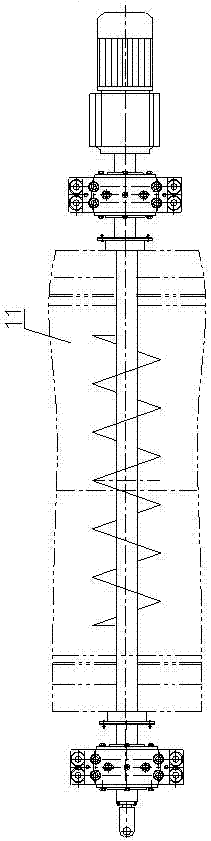

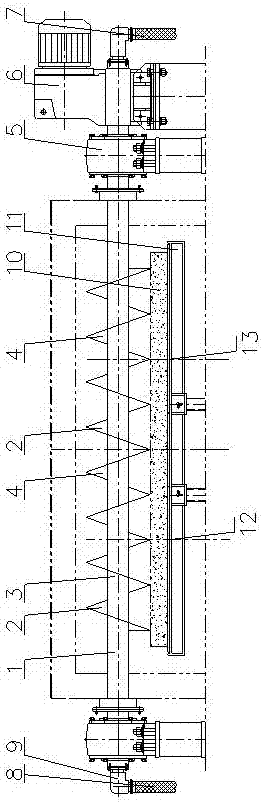

[0033] Hereinafter, in conjunction with the accompanying drawings, the uniform distribution device and method of the present invention which can adapt to various types of materials will be further described in detail.

[0034] according to figure 1 The schematic diagram of the vertical structure of the uniform distribution device of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com