Artificial leather treating agent, polyvinyl chloride artificial leather, preparation method and application thereof

A polyvinyl chloride and artificial leather technology, which is applied in the field of automotive interiors, can solve the problems of friction noise, friction noise, and stiff feel between surface materials and plastic parts, and achieve the effect of good low-temperature bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

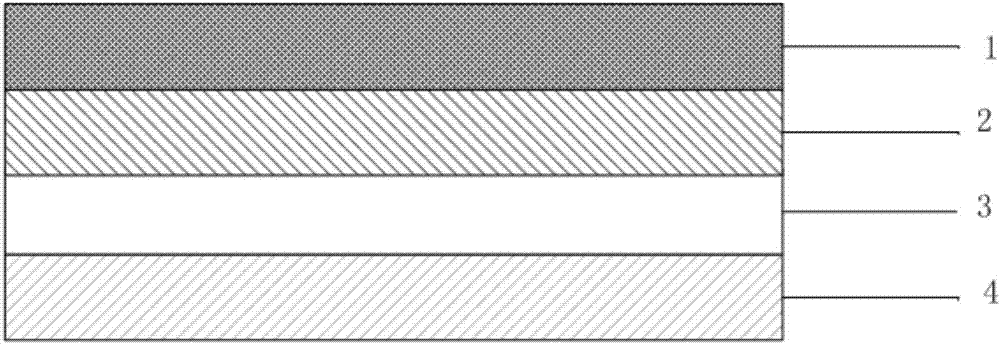

[0074] The invention also discloses a preparation method of polyvinyl chloride artificial leather, comprising the following steps:

[0075] Prepare polyvinyl chloride non-foamed layer and polyvinyl chloride foamed layer respectively;

[0076] placing the polyvinyl chloride foamed layer mixture and the polyvinyl chloride non-foamed layer mixture on the backing fabric in sequence for calendering and bonding to obtain a semi-finished product;

[0077] Coating the artificial leather treatment agent described in the above technical solution on the semi-finished product according to 45-70g / ㎡, forming a treatment layer;

[0078] Foaming and embossing the semi-finished product after forming the treatment layer to obtain polyvinyl chloride artificial leather.

[0079] According to the present invention, the polyvinyl chloride non-foaming layer mixture and the polyvinyl chloride foaming layer mixture are firstly prepared respectively.

[0080] The preparation method of the polyvinyl c...

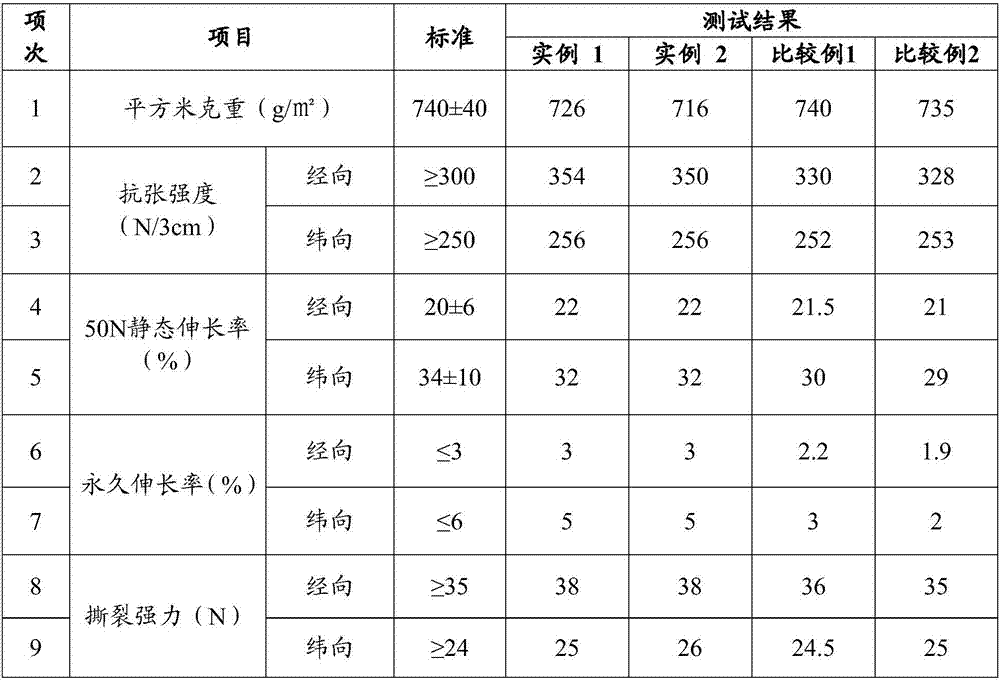

Embodiment 1

[0089] After mixing 3 parts by weight of curing agent; 0.2 parts by weight of defoamer; 1.5 parts by weight of leveling agent; and 8 parts by weight of hand feeling agent, the auxiliary agent is obtained. Get 8 parts by weight of the auxiliary agent and mix it with 100 parts by weight of acrylic acid-modified water-based polyurethane, and use a viscosity modifier to adjust the viscosity to 30 seconds when it flows out through the hole at the bottom of the No. 3 Ford cup to obtain the artificial leather treatment agent.

Embodiment 2

[0091] After mixing 3 parts by weight of curing agent; 0.2 parts by weight of defoamer; 1.5 parts by weight of leveling agent; and 8 parts by weight of hand feeling agent, the auxiliary agent is obtained. Get 6 parts by weight of the auxiliary agent and mix it with 100 parts by weight of acrylic acid-modified water-based polyurethane, and use a viscosity regulator to adjust the viscosity to 40 seconds when it flows out through the hole at the bottom of the No. 3 Ford cup to obtain the artificial leather treatment agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com