Plastic pipeline fire retardant ring

A technology of plastic pipes and fire arresting rings, which is applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of easy falling off of parts, inconvenient, lost installation, etc., to save manpower and cost, save installation time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

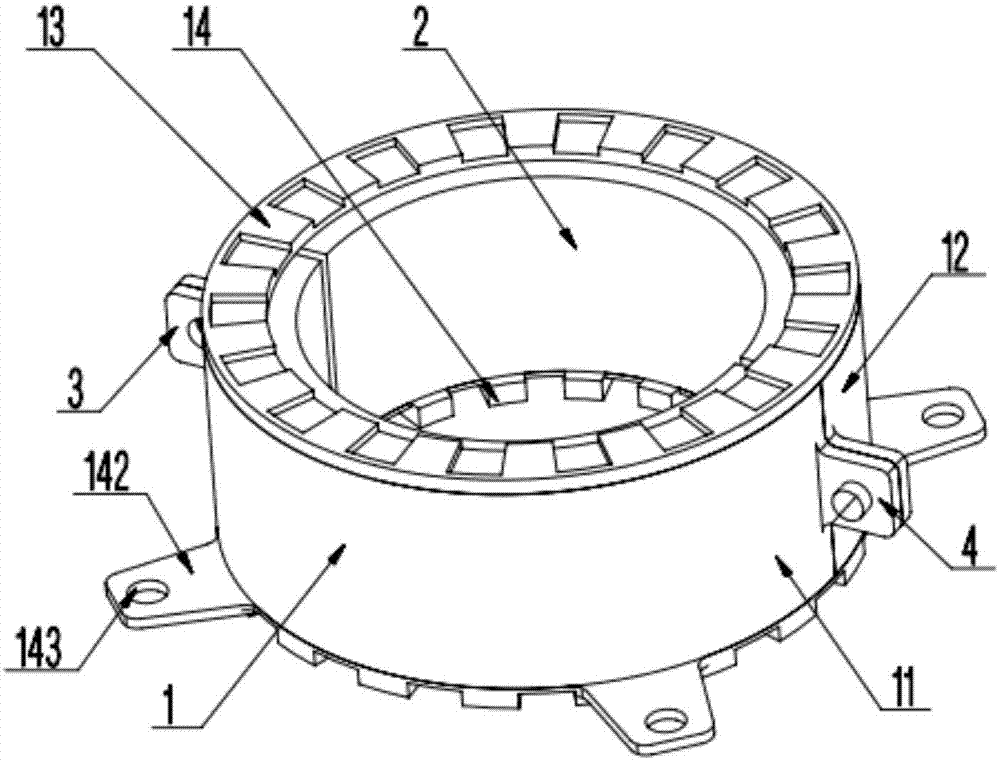

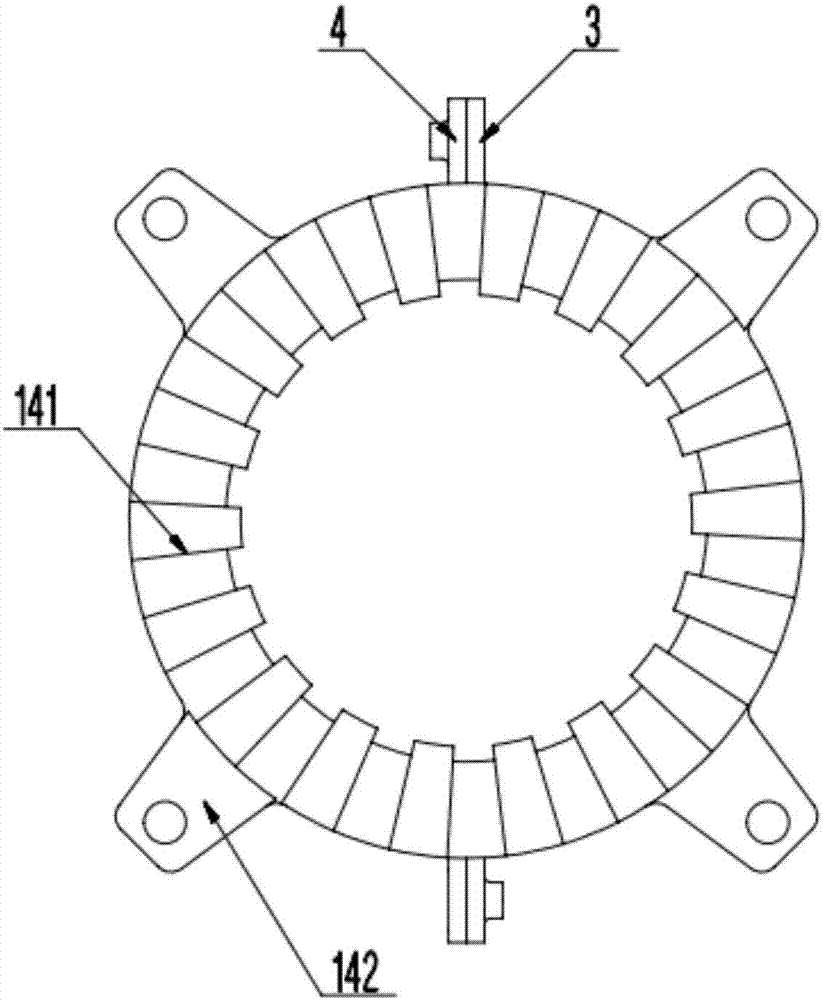

[0036] figure 1 It is a three-dimensional structural schematic diagram of the plastic pipe fire stop ring provided by the embodiment of the present invention; figure 2 is the bottom view of the plastic pipe flame arrester provided by the embodiment of the present invention; such as figure 1 and 2 As shown, this embodiment provides a plastic pipe fire stop ring, including an outer shell 1 and an annular inner core 2; the annular inner core 2 is made of a flame-retardant expansion core material, which is used for thermal expansion and blocking the pipe penetration to prevent The fire spread along the mouth of the cave.

[0037] Preferably, the flame-retardant expanded core material is an annular graphite ribbon.

[0038] Plastic pipes are widely used in all kinds of public and civil buildings, but plastic pipes are often easy to become a channel for fire propagation. The holes formed by plastic pipes after being burned by heat are like a chimney, which makes flames and smoke...

Embodiment 2

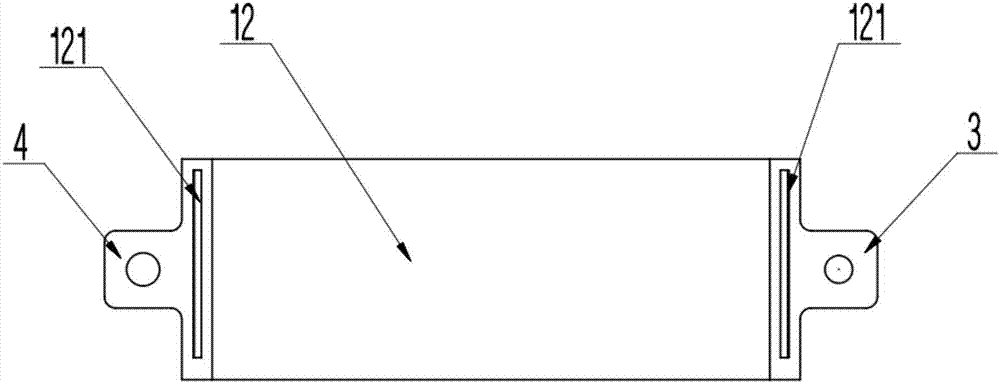

[0045] image 3 Yes figure 1 Front view of the second side housing shown; Figure 4 Yes image 3 a top view of the second side housing shown; Figure 5 Yes figure 1 Front view of the first side housing shown; Image 6 Yes Figure 5 Sectional view at A-A of the first side housing shown; as Figure 3-6 As shown, on the basis of the above-mentioned embodiment, this embodiment further improves the plastic pipe flame arrester. It is integrally formed with the second ear plate 4 .

[0046] Preferably, both the first ear plate 3 and the second ear plate 4 are arranged at the ends of the first side shell 11 and the second side shell 12 .

[0047]Preferably, both the first ear plate 3 and the second ear plate 4 are arranged in the middle position of the junction of the first side shell 11 and the second side shell 12 .

[0048] Preferably, both the first ear plate 3 and the second ear plate 4 are configured as rectangular flat plates.

[0049] Preferably, the connecting surfa...

Embodiment 3

[0054] Figure 7 Yes figure 1 front view of the housing shown; Figure 8 Yes Figure 7 Sectional view shown at housing B-B; as Figure 7 and 8 As shown, on the basis of the above-mentioned embodiment, this embodiment further improves the plastic pipe flame arrester. Specifically, the first side shell 11 is provided with a tongue groove 111, A tongue 121 is provided to be inserted into the tongue groove 111; the tongue groove 111 and the tongue 121 (eg Figure 4 shown) to form an interference fit.

[0055] Preferably, the tongue groove 111 is provided with a convex portion, and the tongue 121 is provided with a concave portion matched with the boss.

[0056] The plastic pipe flame arrester provided by the present invention can strengthen the connection strength between the first side shell 11 and the second side shell 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com