Environment-friendly magnesia-carbon brick heat treatment kiln and treatment method thereof

A heat treatment kiln and magnesia-carbon brick technology, applied in the field of refractory materials, can solve problems such as energy waste, environmental pollution, high calorific value of gas, etc., and achieve the effects of improving thermal efficiency, reducing environmental pollution, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

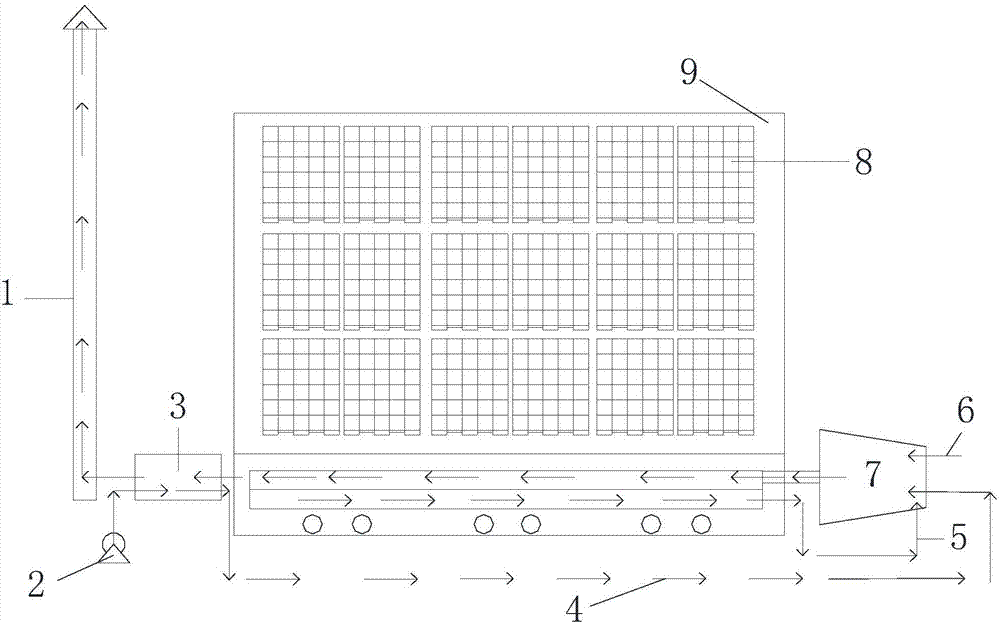

[0023] Please see attached figure 1 As shown, an environmentally friendly magnesia-carbon brick heat treatment kiln includes a chimney 1, a combustion-supporting fan 2, a heat exchanger 3, a combustion-supporting air pipeline 4, a harmful gas volatilization pipeline 5, a combustible gas pipeline 6, a combustion chamber 7, and a plurality of magnesia carbon Bricks 8 and heat treatment kiln body 9; the plurality of magnesia carbon bricks 8 are arranged at intervals in the heat treatment kiln body 9; the combustion-supporting fan 2 is connected to an inlet end of the heat exchanger 3, An output end of the heat exchanger 3 is connected to the inlet end of the combustion air pipeline 4, and an outlet end of the flame retardant air pipeline 4 is connected to an inlet end of the combustion chamber 7; The combustible gas pipeline 6 is connected to the other inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap